Oil and gas burning steam water boiler and outer wetback device thereof

A gas steam and hot water boiler technology, which is applied to the components of steam boilers, steam boilers, and steam boiler accessories, etc., can solve the problems of complex structure, large volume, occupation, etc., and achieve the effect of improving boiler life and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

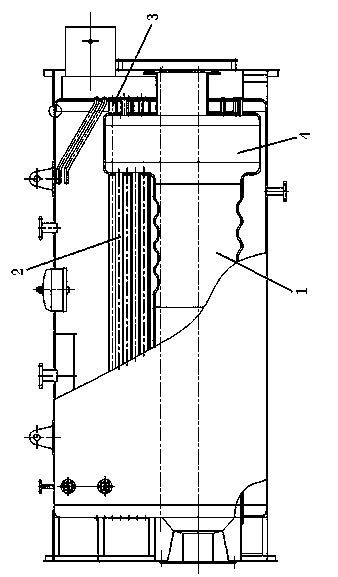

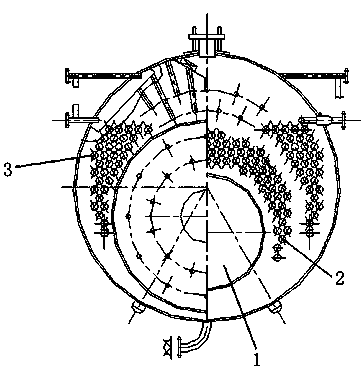

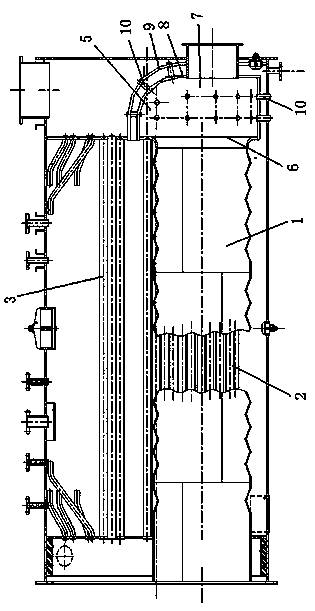

[0015] The invention discloses an external wet back device of a fuel gas steam hot water boiler, such as image 3 with Figure 4 As shown, it includes a smoke chamber 5, the smoke chamber 5 is composed of an outer wet back tube plate 6 located in front of the smoke chamber, a side wet back plate 7 located on both sides and below the smoke chamber, and an internal wet tube plate located behind and above the smoke chamber The inner wet back plate 8 is surrounded by an outer wet back plate 9, and the outer wet back plate 9 and the shell of the boiler are surrounded to form a chamber, and the chamber contains a smoke chamber 5. The inner space of the flue chamber is connected with the first return furnace and the second return flue pipe of the boiler, and the chamber space outside the flue chamber is filled with water to be heated in the boiler.

[0016] Such as Figure 4 As shown, the lower part of the smoke chamber 5 is arc-shaped corresponding to the shape of the boiler shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com