Premixed closed module gas boiler

A gas-fired boiler, mixed-enclosed technology, applied in the burner, combustion method, combustion type, etc., can solve the problems of low thermal efficiency of gas-fired boilers, and achieve the effects of compact structure, long service life and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

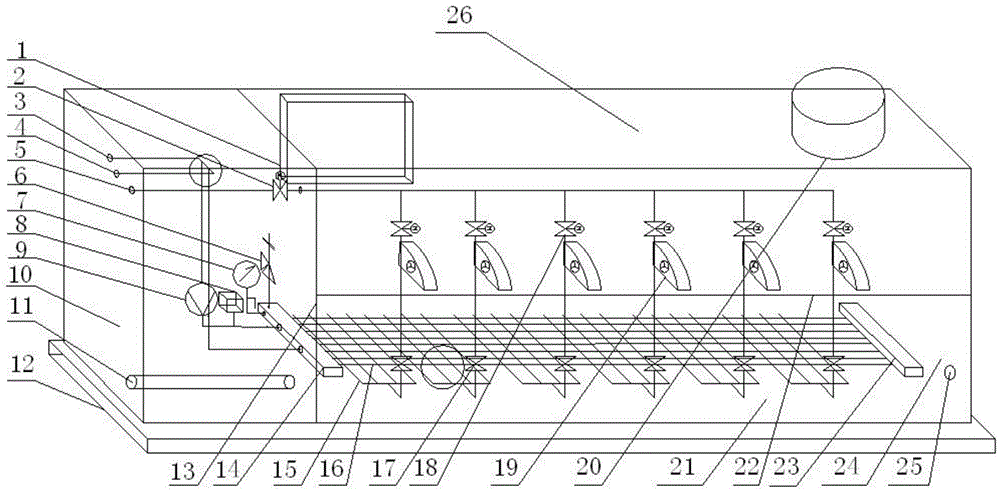

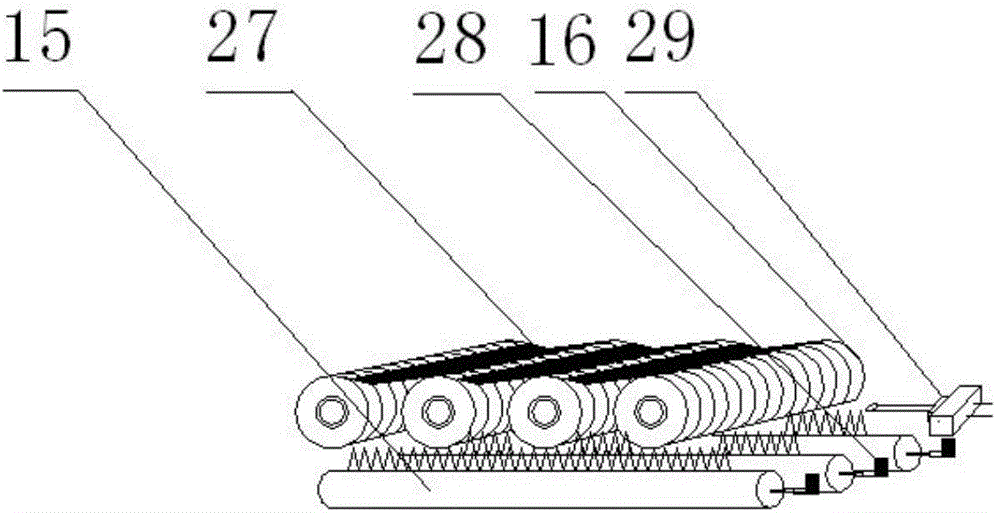

[0032] A premixed airtight modular gas boiler, comprising an upper plate 26, a front plate 10, a rear plate 24 and a side plate 21 to form a single modular boiler with a closed combustion chamber and a base 12;

[0033] The water inlet 3 and the water outlet 4 arranged on the panel 10 are respectively connected to the water inlet of the front sub-collection tank 14 and the water outlet of the water collection tank 14 through the water inlet pipe and the water outlet pipe, wherein the water inlet 3 is connected to the built-in circulating water pump through the water inlet pipe 9 is connected to the water inlet of the previous water diversion tank 14 again; On the pipeline of the water inlet of the diverter water tank 14 before access, a temperature and pressure gauge 7 and a water flow switch 8 have also been installed successively;

[0034] Further, the water inlet pipe and the water outlet pipe are laid in parallel from the water inlet 3 and the water outlet 4, and their term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com