Full-sealed efficient panel type solar heat collector

A solar heat collector, flat-plate technology, applied in solar heat collectors, solar heat collectors using working fluid, solar thermal energy, etc., can solve the inevitable air convection, heat-absorbing coating peeling off, affecting light transmittance and other problems, to achieve the effect of good comprehensive performance of heat insulation, reduce heat loss, and suppress heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following descriptions are only preferred embodiments of the present invention, and are not intended to limit the scope of the present invention. On the premise of not departing from the design concept of the present invention, various modifications and improvements made to the technical solutions of the present invention shall fall within the scope of the present invention. within the scope of protection determined by the claims.

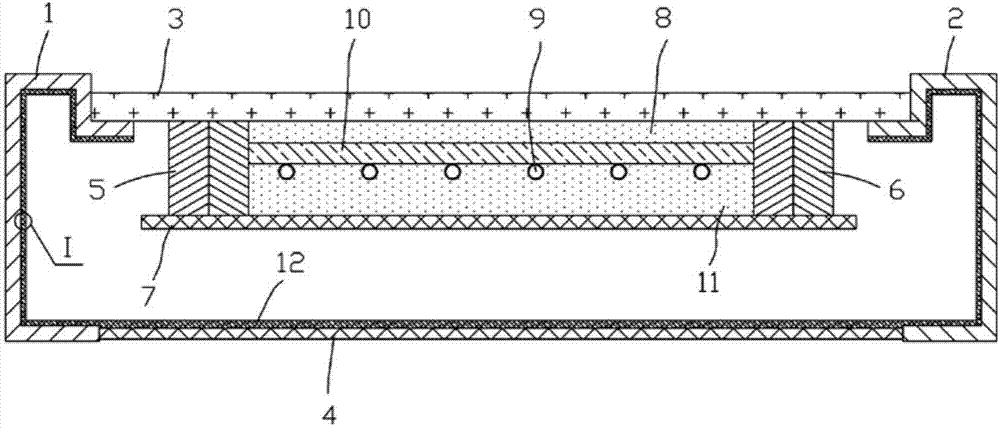

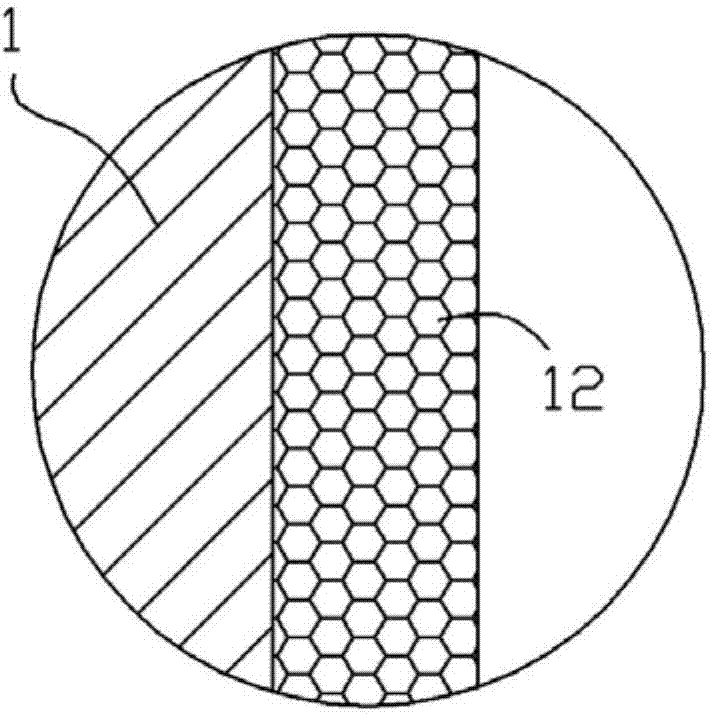

[0016] Examples, see attached Figure 1~2 As shown: a fully sealed high-efficiency flat-plate solar collector, including a left frame 1 and a right frame 2, and a glass cover plate 3 and a back plate 4 are fixed between the left and right frames 1 and 2; the glass cover plate 3 Left and right aluminum strip partitions 5,6 are fixed on the lower surface of the bottom surface, and a baffle plate 7 is fixed on the left and right aluminum strip partitions 5,6, and the left and right aluminum strip partitions 5 and the left and right aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com