A circuit board of an igbt module

A technology of circuit boards and substrates, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of reduced reliability of IGBT modules, uneven current flow of chips with saturated voltage drop, complicated connection procedures, etc., to reduce the occupied installation volume, The structure of the circuit board is simple, and the effect of fast and accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

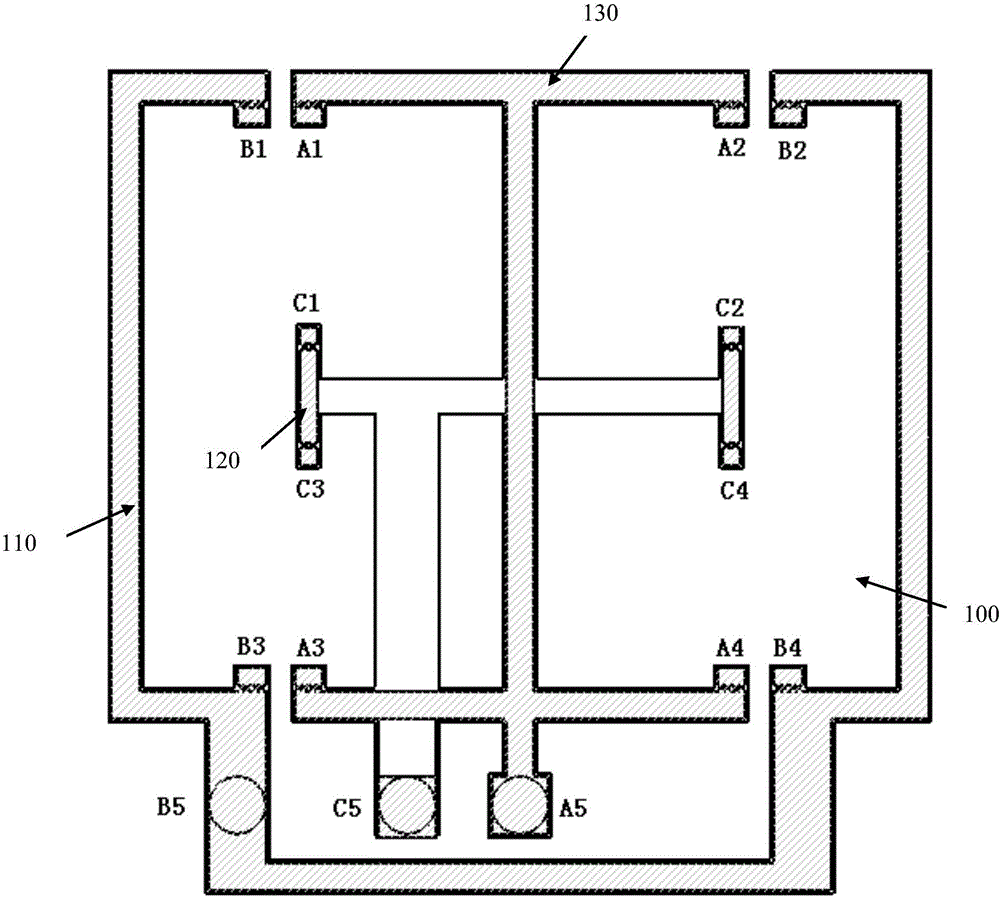

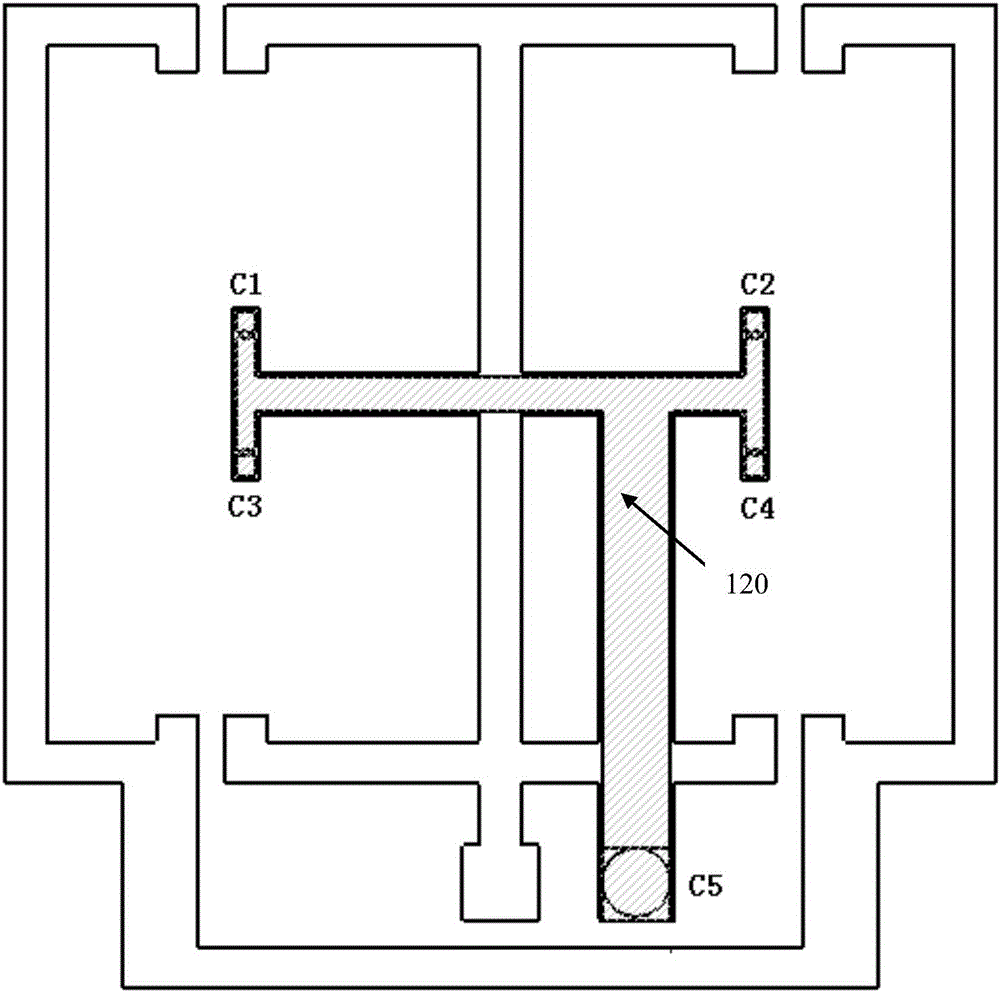

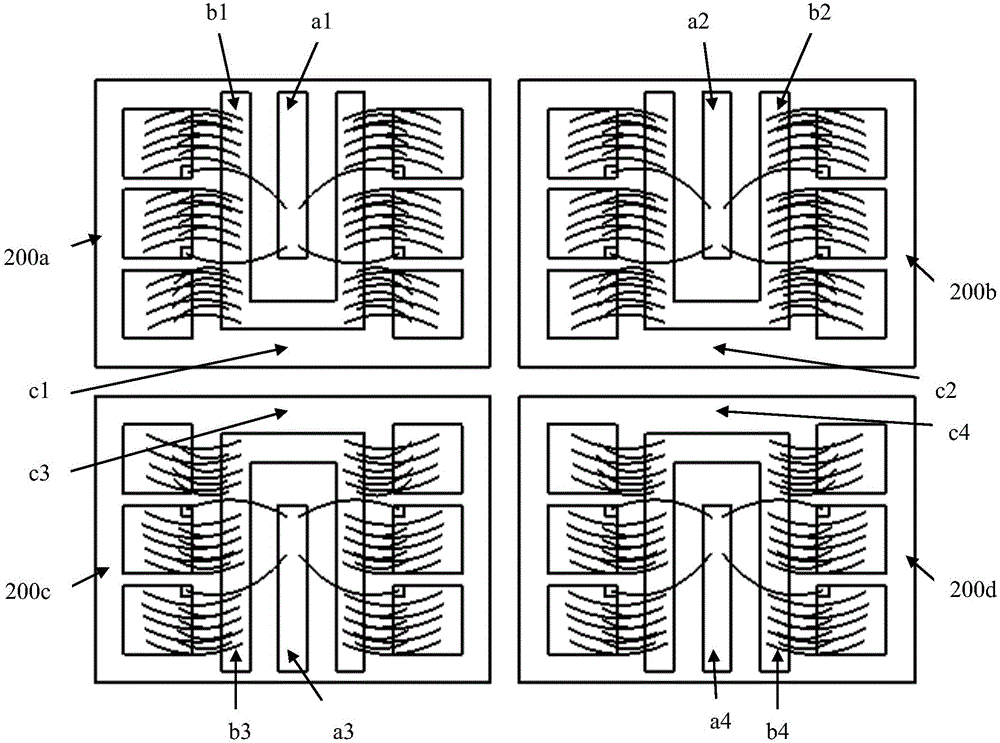

[0027] The embodiment of the invention discloses a circuit board of an IGBT module. The IGBT module includes at least two IGBT module subunits, and each IGBT module subunit is arranged on the circuit board, wherein the circuit board is an insulating substrate on which a module Conductive domains drawn from the emitter electrode, conductive domains drawn from the collector electrode of the module, and conductive domains drawn from the module grid. The domain-connected subunit emitter lead-out point, subunit collector lead-out point and subunit gate lead-out point are used for the parallel connection between the subunits of each IGBT module.

[0028] Preferably, an IGBT module emitter lead-out point, an IGBT module collector lead-out point and an IGBT module gate lead-out point are respectively provided on the module emitter lead-out conductive domain, the module collector lead-out conductive domain and the module gate lead-out conductive domain, for Electrically reliable lead-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com