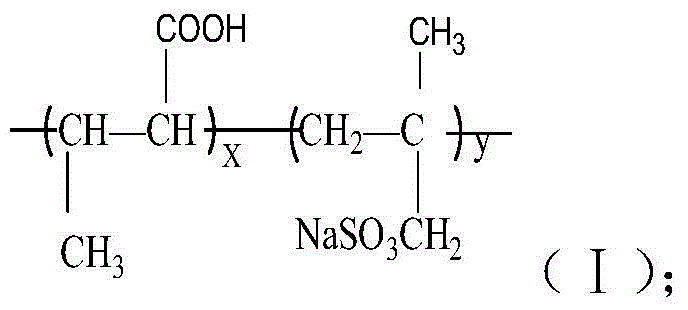

A kind of crotonic acid copolymer dispersant and its preparation method and application

A kind of copolymer and crotonic acid technology, applied in the direction of coating, etc., can solve the problems that the coating is easily affected by the solvent, the environmental protection performance of the coating is reduced, and the dispersion effect is not very good, so as to save time and raw materials, not easy to settle, and reduce synthesis The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

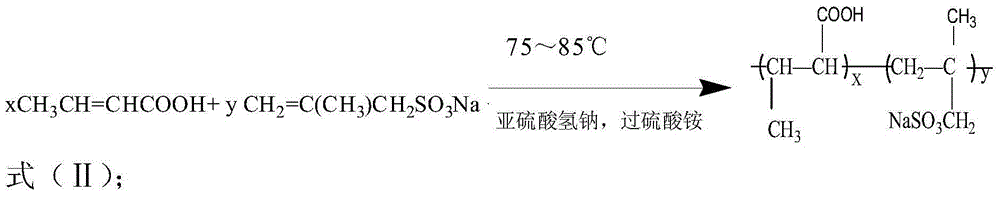

[0039] A preparation method of crotonic acid copolymer dispersant, comprising the following steps:

[0040] (1) In a 250mL four-neck flask equipped with a stirrer, dropping funnel, thermometer and reflux condenser, add 1.1 parts of crotonic acid, 1 part of sodium methacrylate and 0.04 parts of sodium bisulfite, add distilled water for 20 part, then stirred and dissolved to obtain a mixed solution;

[0041] (2) Heat the mixed solution to 75°C; then slowly add dropwise an aqueous solution containing 0.15 parts of ammonium persulfate at a rate of 1 drop / second, and complete the dropwise addition within half an hour, then keep warm for 3 hours and then stop the reaction to obtain a polymer ;

[0042] (3) Cool the polymer to 40°C; slowly add NaOH solution with a mass fraction of 30% dropwise to make the pH of the system 8-9, and finally obtain a light yellow transparent liquid, namely the crotonic acid copolymer dispersant A.

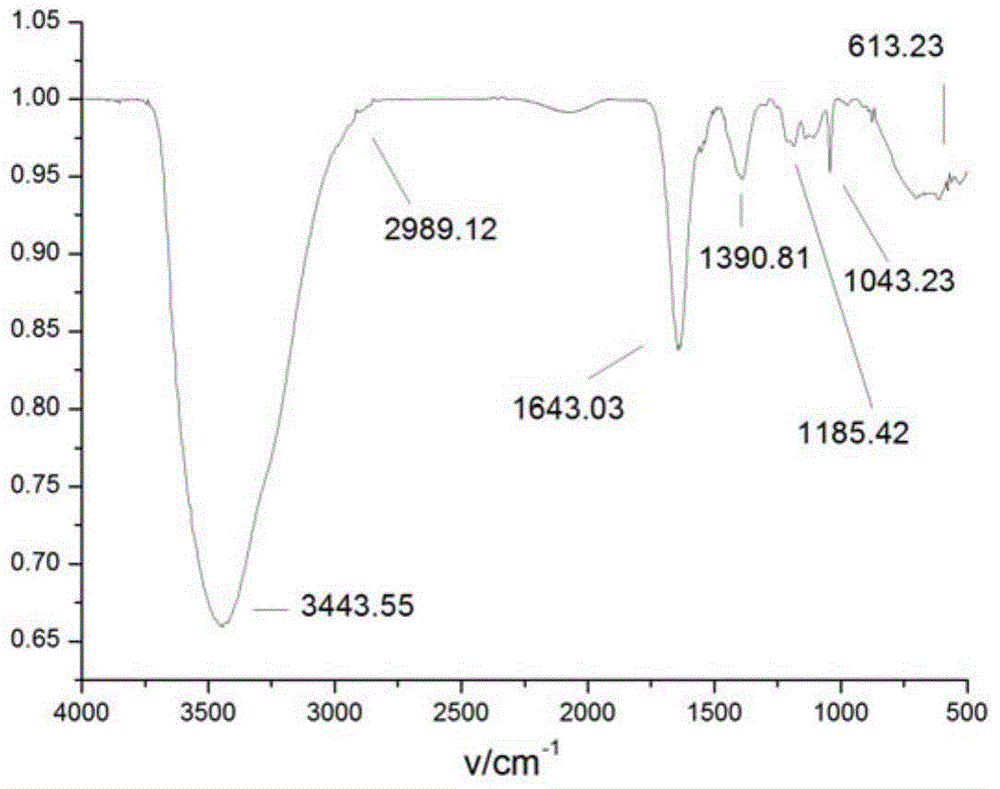

[0043] attached figure 1 For the infrared spectrum ...

Embodiment 2

[0045] A preparation method of crotonic acid copolymer dispersant, comprising the following steps:

[0046] (1) In a 250mL four-neck flask equipped with a stirrer, dropping funnel, thermometer and reflux condenser, add 2.2 parts of crotonic acid, 1.5 parts of sodium methacrylate and 0.06 parts of sodium bisulfite, add distilled water for 25 part, then stirred and dissolved to obtain a mixed solution;

[0047] (2) Heat the mixed solution to 85°C; then slowly add ammonium persulfate (0.2 parts) aqueous solution dropwise at a rate of 1 drop / second, the dropwise addition is completed within half an hour, and then keep warm for 3.5 hours to stop the reaction to obtain polymerization thing;

[0048] (3) Cool the polymer to 50°C; slowly add NaOH solution with a mass fraction of 30% dropwise to make the pH of the system 8-9, and finally obtain a light yellow transparent liquid, that is, crotonic acid copolymer dispersant B.

[0049] The obtained product infrared spectrum data is as ...

Embodiment 3

[0051] A preparation method of crotonic acid copolymer dispersant, comprising the following steps:

[0052] (1) In a 250mL four-neck flask equipped with a stirrer, dropping funnel, thermometer and reflux condenser, add 3.3 parts of crotonic acid, 2 parts of sodium methacrylate and 0.08 parts of sodium bisulfite, add distilled water for 30 part, then stirred and dissolved to obtain a mixed solution;

[0053] (2) Heat the mixture to 80°C; then slowly add ammonium persulfate (0.25 parts) aqueous solution dropwise, the speed is controlled at 1 drop / second, and the dropwise addition is completed within half an hour, and then keep warm for 2.5 hours to stop the reaction to obtain polymerization thing;

[0054] (3) Cool the polymer to 50°C; slowly add NaOH solution with a mass fraction of 30% dropwise to make the pH of the system 8-9, and finally obtain a light yellow transparent liquid, that is, crotonic acid copolymer dispersant C.

[0055] The obtained product infrared spectrum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com