Tappet bottom face height difference gauge

A technology of height difference and pillar bottom, which is applied in the field of project detection of the geometric characteristics of tappet products, can solve the problems of disputes in measurement results, difficulty in determining the reference plane, and high measurement costs, so as to avoid long measurement time, accurate measurement results, and solve problems. Build puzzle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

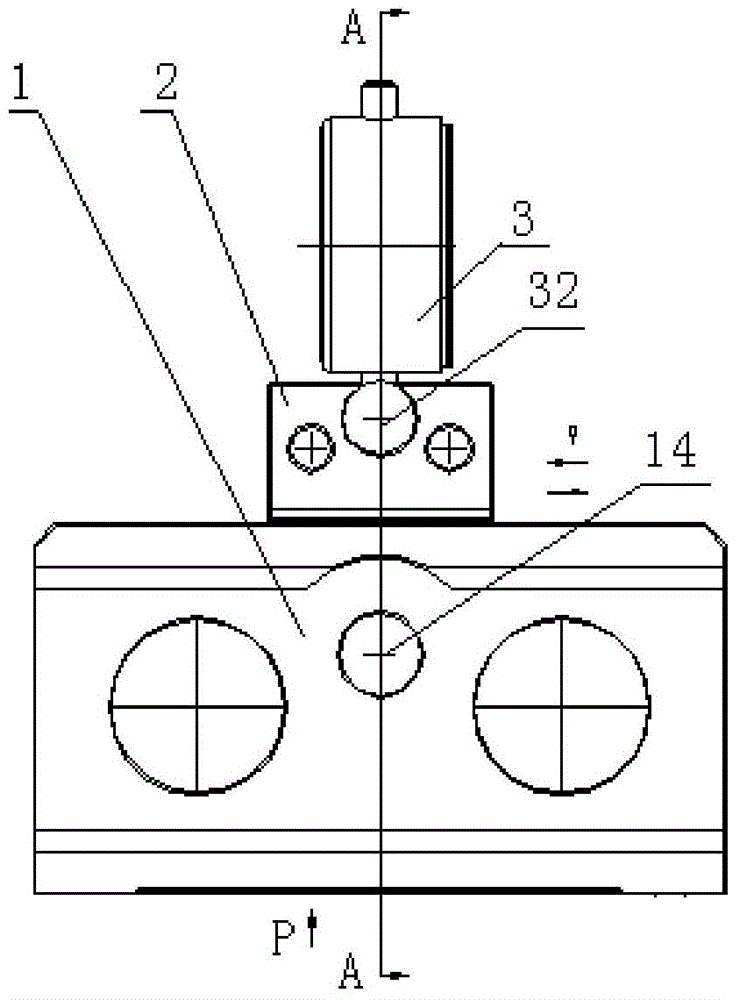

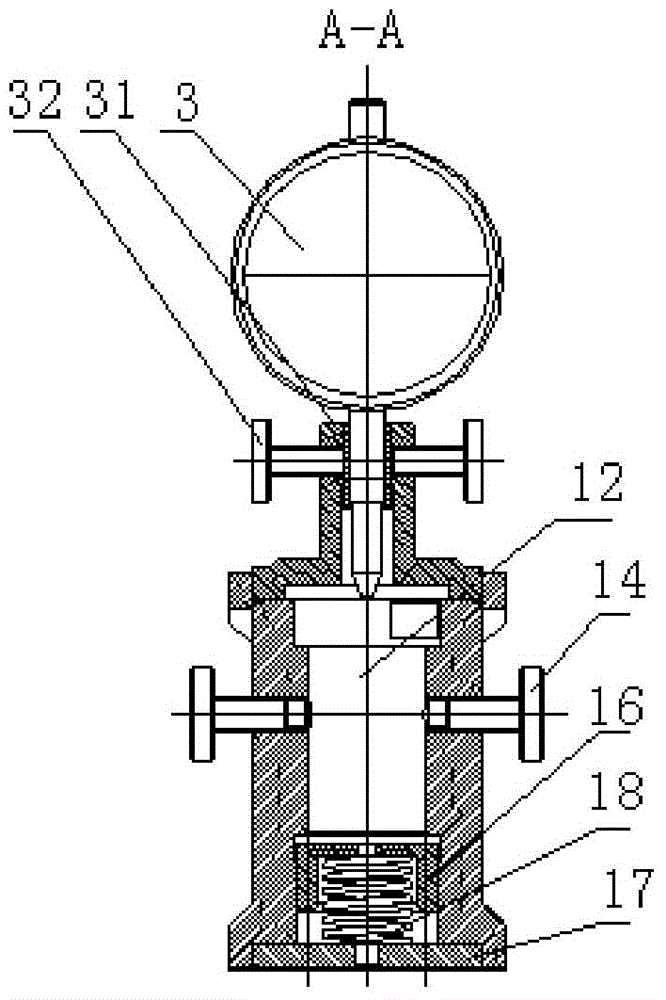

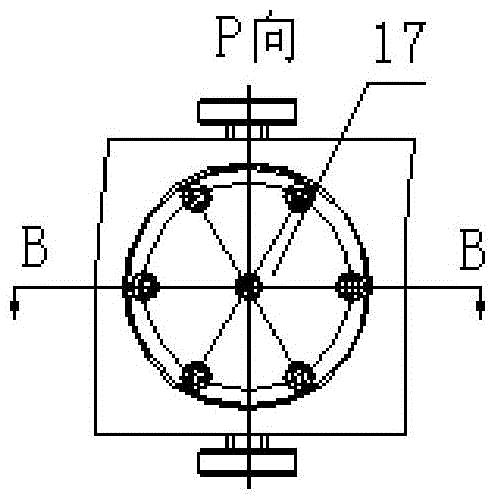

[0029] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment. It should be understood that the "upper", "lower", "left", "right", "front" and "reverse" mentioned in the following embodiments of the present invention are all based on the directions shown in the figures, These words used to limit the direction are only for convenience of description, and do not mean to limit the specific technical solution of the present invention.

[0030] The structure of the tappet bottom surface height difference checker of the present invention is simple and reasonable, and the checker body with guide grooves and the table frame slider with two guide sides are designed to be used in pairs, which can ensure that the measuring head touches each time. The path is the same, which solves the problem of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com