Automatic control device of powder height

An automatic control device and high-level technology, applied in non-electric variable control, liquid level control, control/regulation systems, etc., can solve problems such as production process errors and product quality decline, and achieve real-time control and improve the quality of finished drugs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

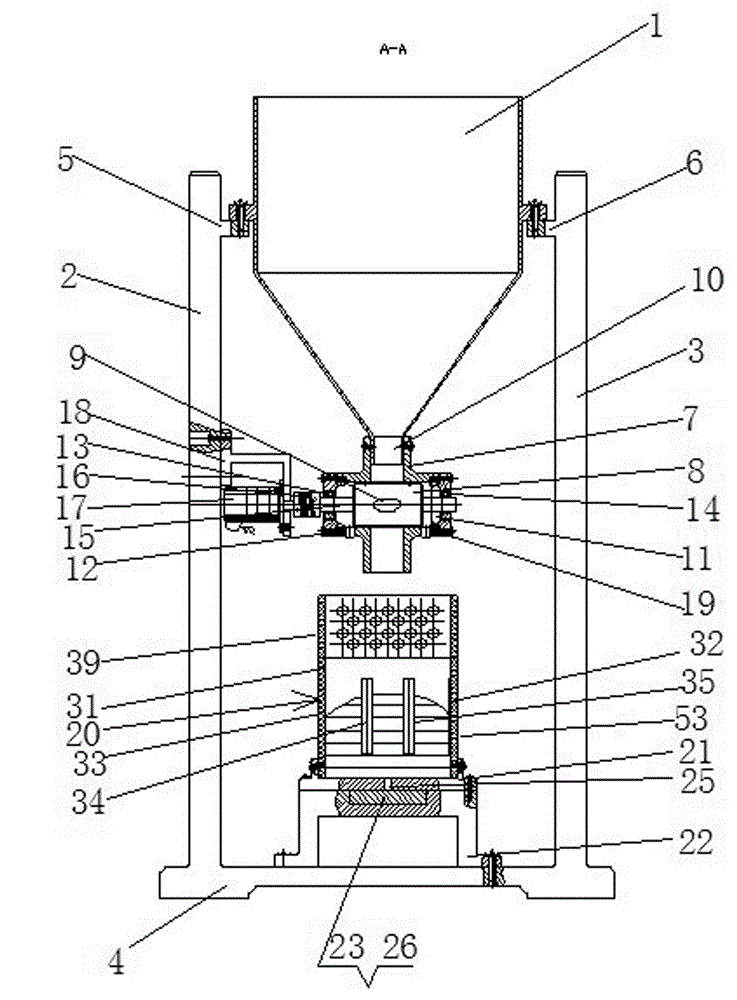

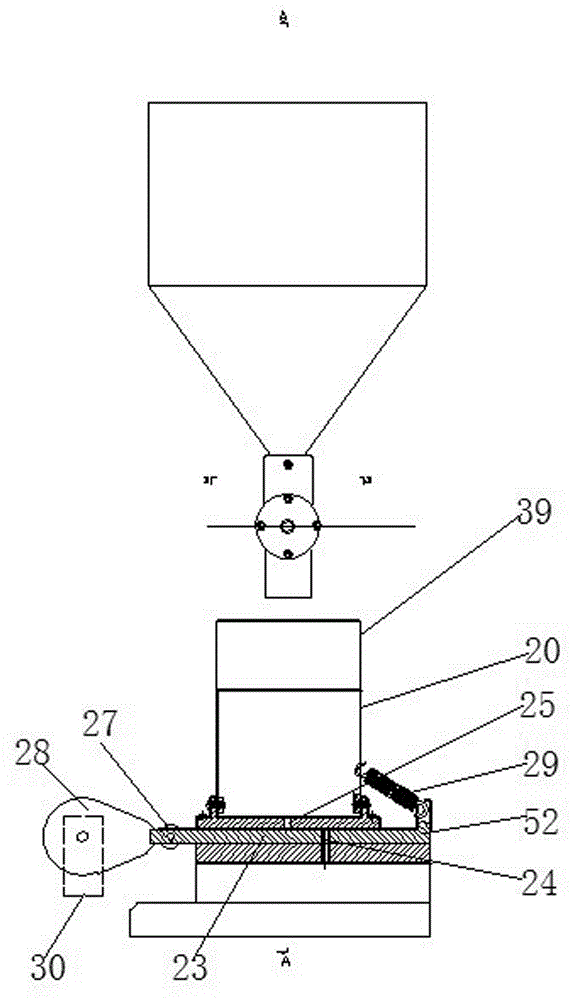

[0030] An automatic powder height control device includes a hopper 1, a feeding mechanism, a powder height detection mechanism and a bracket assembly.

[0031] The bracket assembly includes the left support plate 2, the right support plate 3 and the bottom plate 4, the left support plate 2 and the right support plate 3 are vertical and arranged in parallel, the left support plate 2 and the right support plate 3 The lower ends are respectively fixedly connected with the bottom plate 4 . There are left boss 5 and right boss 6 respectively at the corresponding positions of the upper ends of the left side support plate 2 and the right side support plate 3, and the two lifting lugs on the hopper 1 are fixedly connected with the left boss 5 and the right boss 6 respectively. It is characterized by:

[0032] The feeding mechanism includes a stepper motor 17, a feeding device 7 and a feeder 8, the feeder 8 is cylindrical, and the feeder 8 is provided with a trough 9. Blanking device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com