3D Realistic Digital Prototyping System and Construction Method for Spacecraft Assembly

A spacecraft assembly and digital prototyping technology, applied in the fields of electrical digital data processing, instruments, and special data processing applications, etc., can solve the problem of inability to realize association, difficulty in technical state control by craftsmen, inconvenient design and change of entire star product data package, etc. problem, to achieve the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

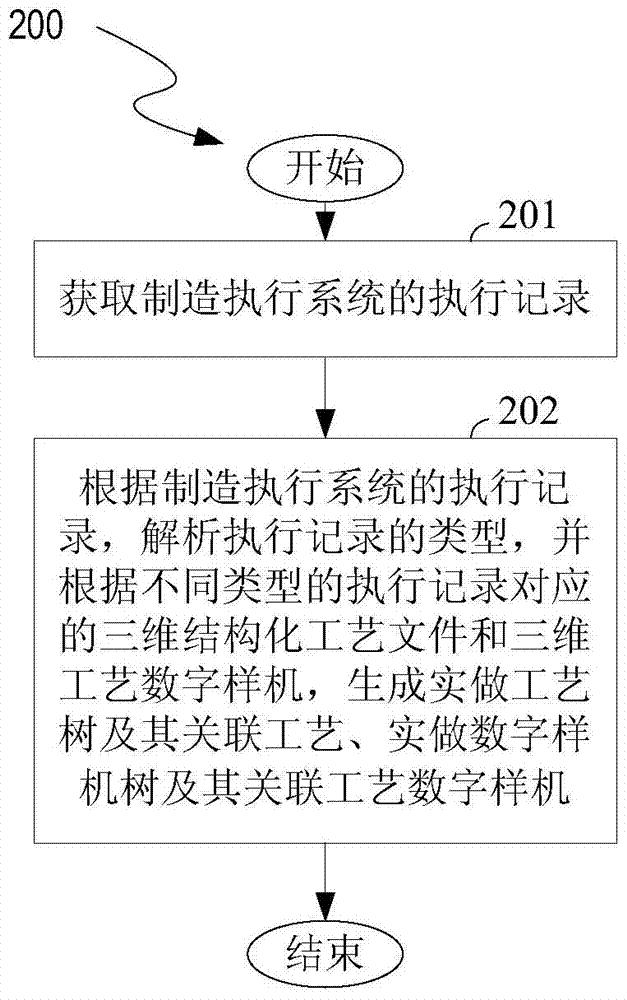

[0012] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

[0013] The present invention provides a three-dimensional actual digital prototype system and a three-dimensional actual digital prototype construction method for spacecraft assembly, to improve the efficiency of process preparation, and implement structured control and information collection on site through structured state parameters.

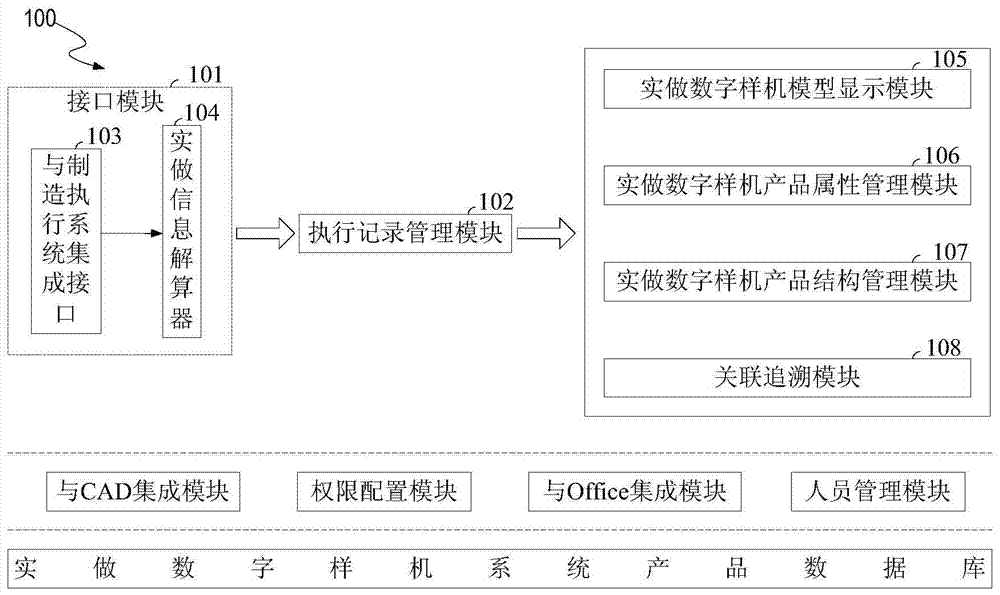

[0014] figure 1 Shown is a structural diagram of a three-dimensional digital prototype system 100 for spacecraft assembly according to the present invention. The three-dimensional digital prototype system 100 includes an interface module 101, an execution record management module 102, a digital prototype product structure management module 107, a digital prototype product attribute management module 106, a digital prototype model display module 105, and an associated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com