PLC glow control method and device for diamond growth

A control method, diamond technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of not being able to provide good conditions for diamond growth, and not being able to achieve organic unity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

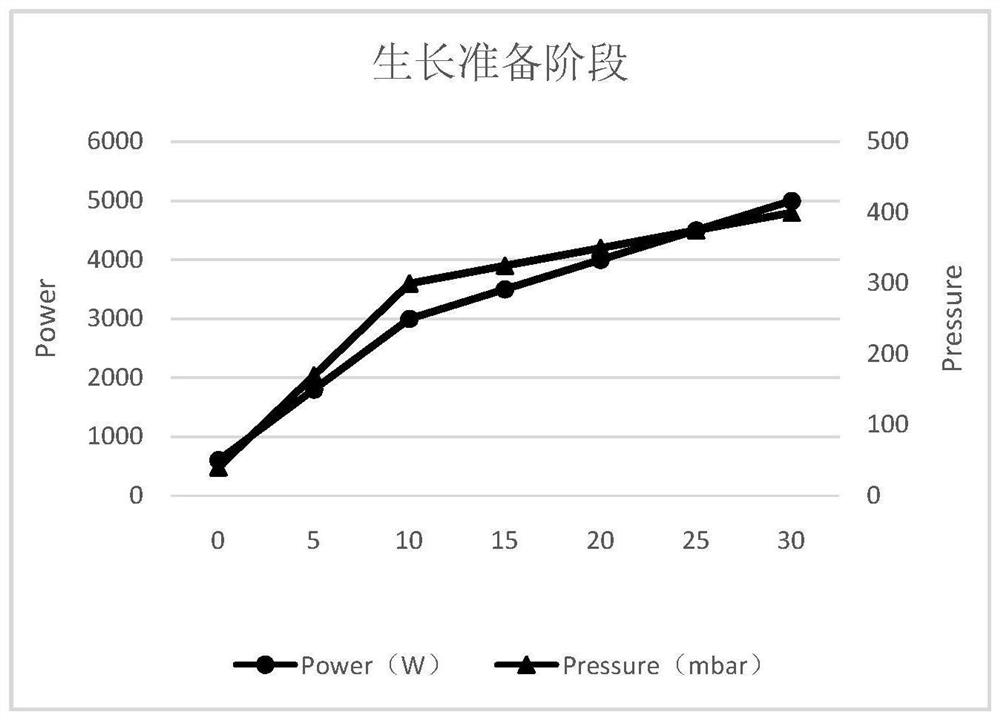

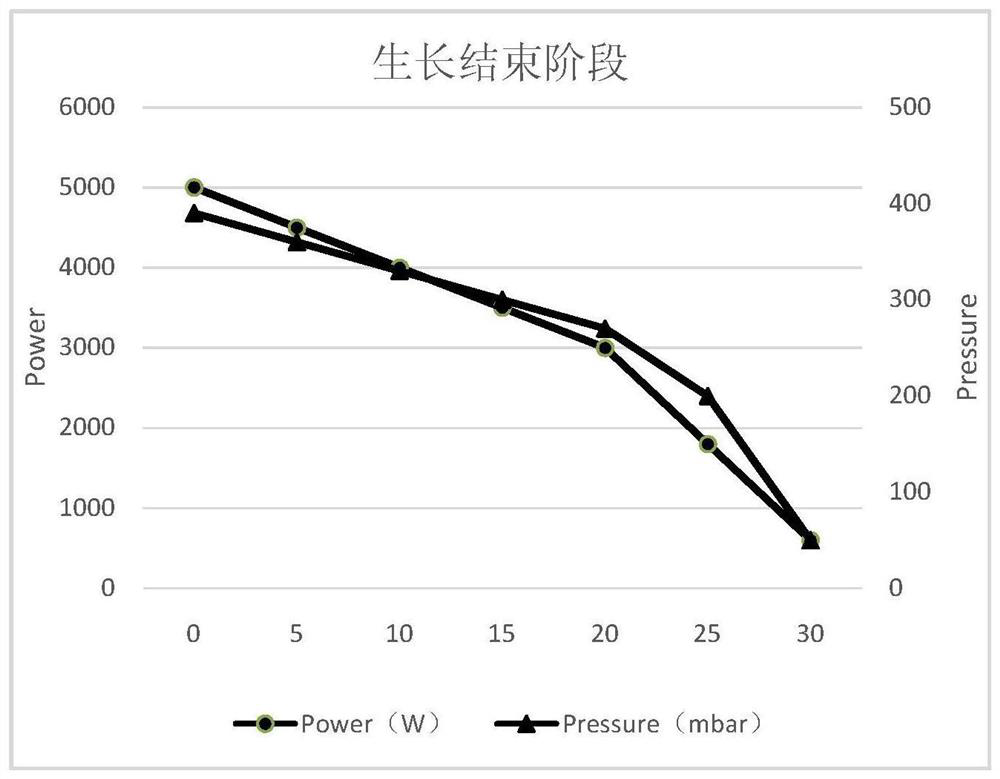

[0052]During the diamond growth process, it is necessary to control the glow discharge, which is the basic condition to ensure the normal growth of the crystal. According to the requirements of the diamond process, this embodiment divides the glow control into three stages: the growth preparation stage, the growth maintenance stage and the growth end stage, and describes the PLC glow control method in combination with each stage.

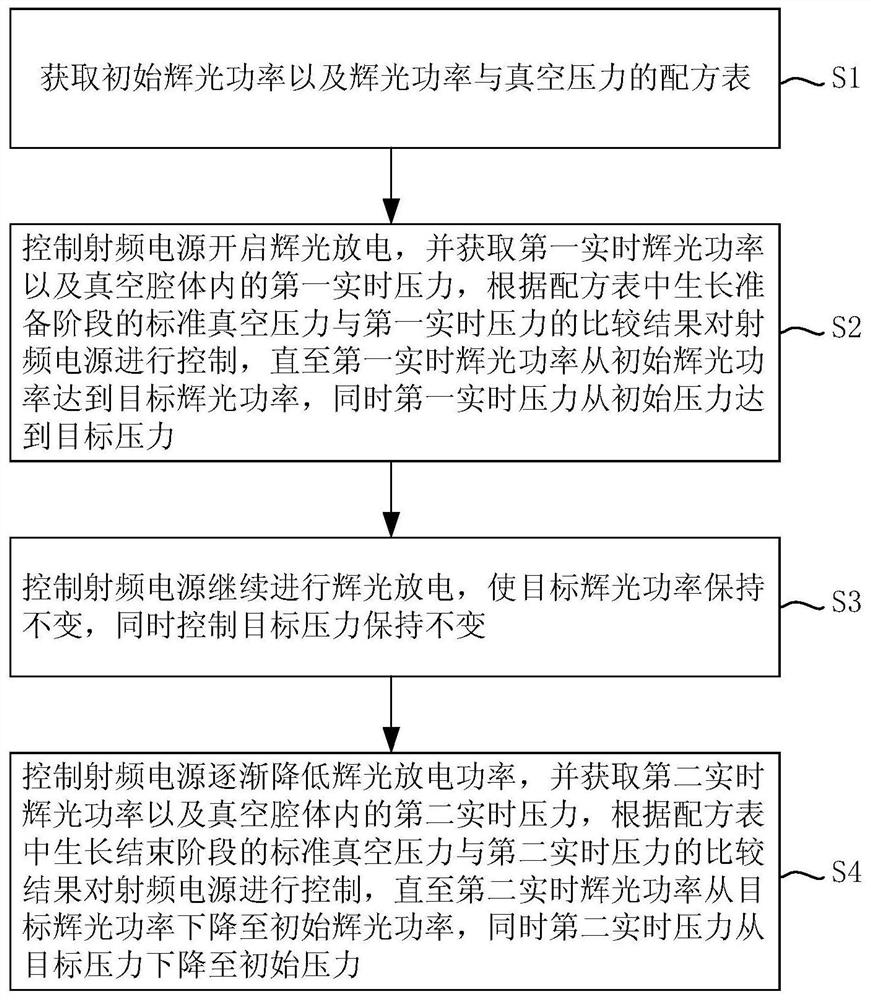

[0053] See figure 1 , figure 1 It is a schematic flowchart of a PLC glow control method for diamond growth provided by an embodiment of the present invention. The PLC glow control method comprises steps:

[0054] S1. Obtain the initial glow power and the formula table of glow power and vacuum pressure.

[0055] Specifically, the operator sets the glow parameters on the host computer, including setting the initial glow power and the recipe table of glow power and vacuum pressure during the diamond growth process, and the PLC controller obtains the...

Embodiment 2

[0070] On the basis of Example 1, please refer to Figure 4 , Figure 4 It is a schematic flowchart of another PLC glow control method for diamond growth provided by the embodiment of the present invention. The PLC glow control method comprises steps:

[0071] S1. Obtain the initial glow power and the formula table of glow power and vacuum pressure.

[0072] S2. Control the radio frequency power supply to turn on the glow discharge, and obtain the first real-time glow power and the first real-time pressure in the vacuum chamber, and compare the radio frequency power supply according to the comparison result between the standard vacuum pressure in the growth preparation stage and the first real-time pressure in the formula table Controlling is performed until the initial glow power reaches the target glow power, and at the same time the initial pressure in the vacuum chamber reaches the target pressure.

[0073] S3. Control the radio frequency power supply to continue the gl...

Embodiment 3

[0084] On the basis of Embodiment 1 and Embodiment 2, please refer to Figure 5 , Figure 5 It is a schematic structural diagram of a PLC glow control device for diamond growth provided by an embodiment of the present invention. The PLC glow control device includes a parameter acquisition module 51 , a glow discharge enabling module 52 , a glow discharge maintaining module 53 and a glow discharge closing module 54 . in,

[0085] The parameter obtaining module 51 is used to obtain the initial glow power and the formula table of glow power and vacuum pressure. The glow discharge start module 52 is connected with the parameter acquisition module 51, and is used to control the radio frequency power supply to start the glow discharge, and obtain the first real-time glow power and the first real-time pressure in the vacuum chamber, according to the standards in the growth preparation stage in the formula table The comparison result of the vacuum pressure and the first real-time p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com