Horse oil containing moisturizing and nourishing cosmetic composite and preparation method thereof

A technology for cosmetic compositions and compounds, which is applied in the field of skin care products to achieve the effects of obvious effects, unique formulas and stable processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

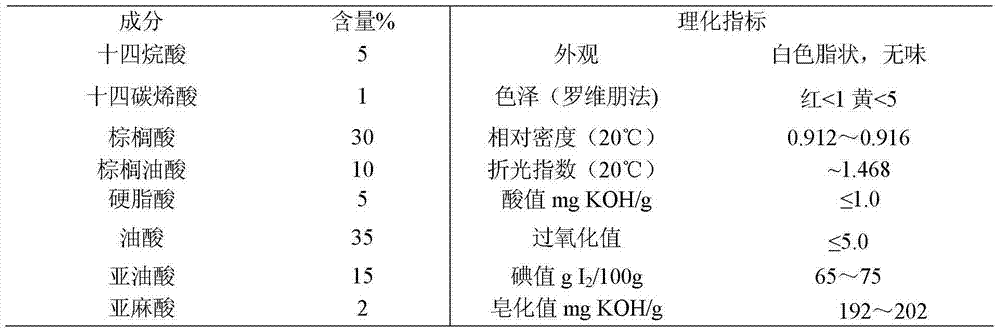

Method used

Image

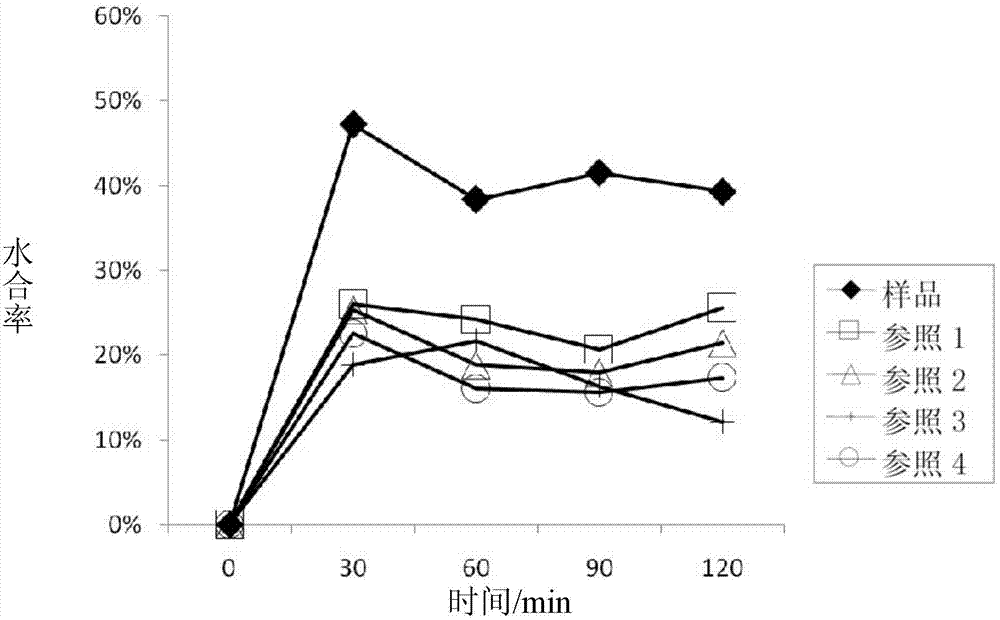

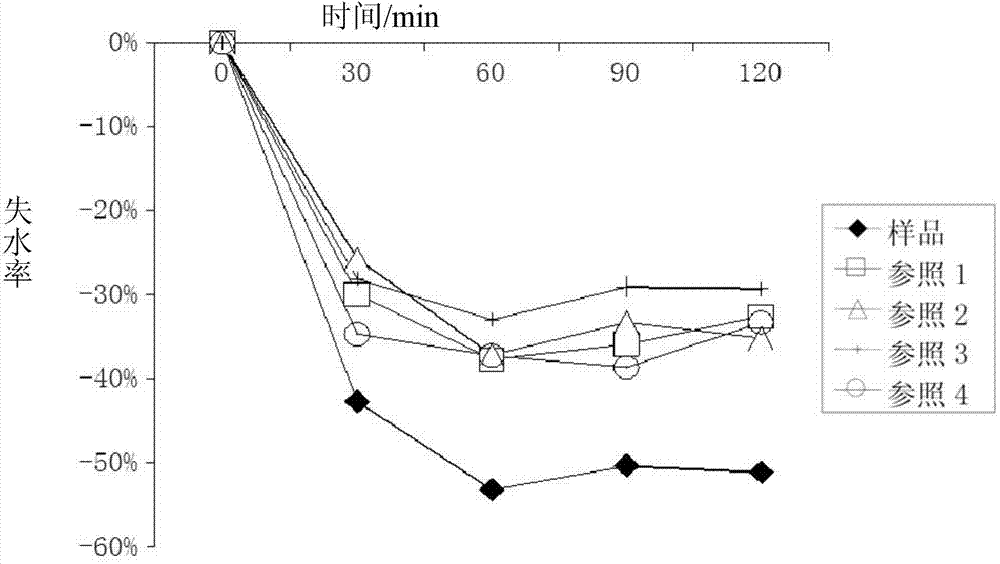

Examples

Embodiment 1

[0058]

[0059] Production process: Add the raw materials in phase A except tocopherol acetate to the oil phase reaction kettle in sequence, add the raw materials in phase B to the water phase reaction kettle, suck all the oil phase into the vacuum emulsification kettle after filtration, add Tocopheryl acetate. Start the scraper to stir. After filtration, all the oil phase is sucked into the vacuum emulsification tank, and then the water phase is sucked through filtration. Turn on stirring and homogeneous emulsification. At this time, the temperature in the emulsification tank should not be lower than 80°C. Keep warm and stir for 10-15 minutes, then start to cool down. When the temperature drops below 70°C, add Carbomer 981 (2% aqueous solution) in phase C, stir evenly, and add neutralizing agent sodium hydroxide solution when the temperature drops below 60°C; when the temperature of the paste drops to 45°C, add phase C For other materials, fully stir and discharge at 35...

Embodiment 2

[0061]

[0062] Production process: Add the raw materials in phase A except tocopherol acetate to the oil phase reaction kettle in sequence, add the raw materials in phase B to the water phase reaction kettle, suck all the oil phase into the vacuum emulsification kettle after filtration, add Tocopheryl acetate. Start the scraper to stir. After filtration, all the oil phase is sucked into the vacuum emulsification tank, and then the water phase is sucked through filtration. Turn on stirring and homogeneous emulsification. At this time, the temperature in the emulsification tank should not be lower than 80°C. Keep warm and stir for 10-15 minutes, then start to cool down. When the temperature drops below 70°C, add U20 (2% aqueous solution) in phase C, stir evenly, and add neutralizing agent sodium hydroxide solution when the temperature drops below 60°C to adjust the pH value; when the temperature of the paste drops to 45°C, add C With other materials, fully stir and discha...

Embodiment 3

[0064]

[0065] Production process: Add the raw materials in phase A except tocopherol acetate to the oil phase reaction kettle in sequence, add the raw materials in phase B to the water phase reaction kettle, suck all the oil phase into the vacuum emulsification kettle after filtration, add Tocopheryl acetate. Start the scraper to stir. After filtration, all the oil phase is sucked into the vacuum emulsification tank, and then the water phase is sucked through filtration. Turn on stirring and homogeneous emulsification. At this time, the temperature in the emulsification tank should not be lower than 80°C. Keep warm and stir for 10-15 minutes, then start to cool down. When the temperature drops below 70°C, add Carbomer 934 (3.5% aqueous solution) in phase C, stir evenly, and add neutralizing agent sodium hydroxide solution when the temperature drops below 60°C; when the temperature of the paste drops to 45°C, add phase C For other materials, fully stir and discharge at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com