A kind of composite solder cored aluminum welding wire and preparation method thereof

A technology of flux-cored aluminum welding wire and composite solder, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as difficult brazing and inability to prepare solder, and achieve low melting point of solder and short alloying time , The effect of uniform composition of weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

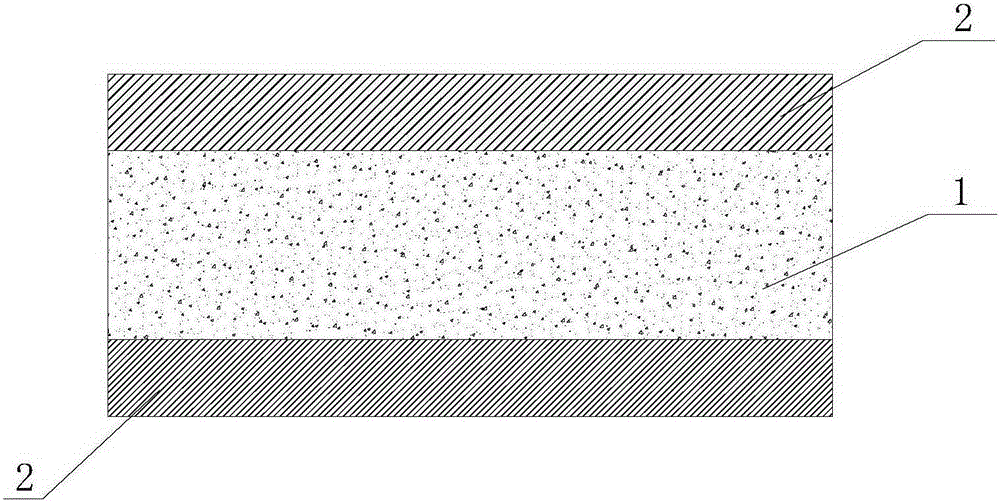

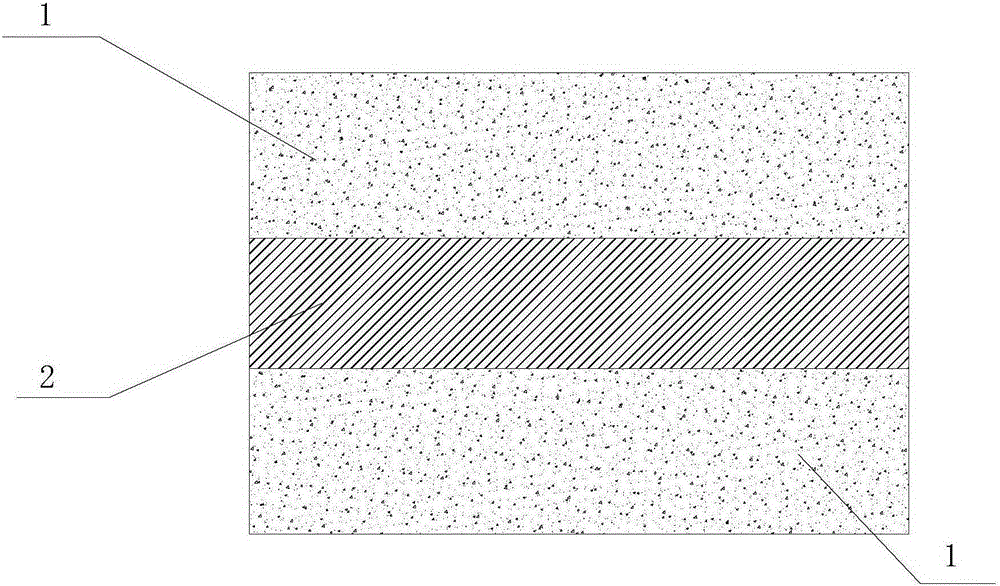

[0035] In the metal composite solder cored aluminum welding wire in the present embodiment, the outer skin is a metal composite solder, such as image 3 As shown, the aluminum alloy layer 1 is 4045 aluminum alloy, and the copper layer 2 is Cu.

[0036] Its preparation method is:

[0037] According to the thickness ratio 4045: Cu: 4045=5:1:5, the 4045 aluminum alloy, copper and 4045 aluminum alloy are rolled into a composite strip through a rolling mill; the composite strip is thinned to 0.3-0.6mm, and the strip width is 9 ~12mm; the prepared composite strip is rolled into a U shape through a rolling mill; the U-shaped composite strip is rolled into an O shape after adding a drug core; the diameter is reduced to 2.4~3.0mm; continue to reduce the diameter and make Composite solder flux-cored aluminum welding wire with a diameter of 1.0-3.0mm. Among them, Cu accounts for 24.8% of the total weight of the solder, Si accounts for 8.5% of the total weight of the solder, and the res...

Embodiment 2

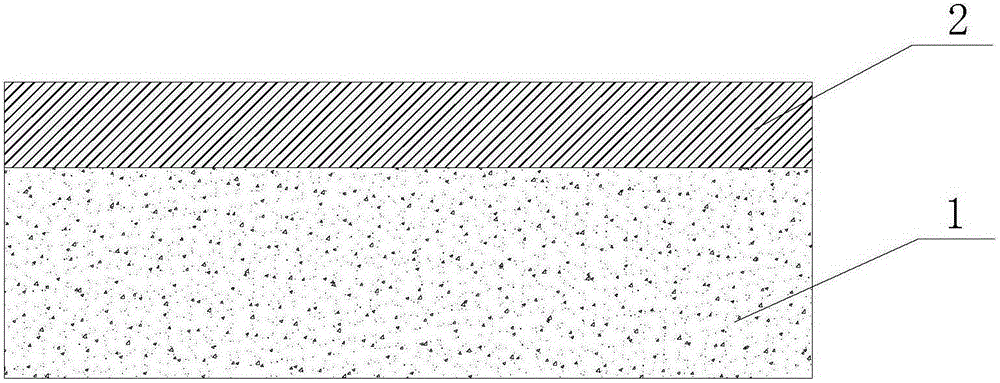

[0039] In the metal composite solder cored aluminum welding wire in the present embodiment, the outer skin is a metal composite solder, such as figure 2 As shown, the aluminum alloy layer 1 is Al-Si-Zn alloy, and the copper layer 2 is Cu. According to the thickness ratio of aluminum alloy layer: copper layer = 50:1, the Al-Si-Zn alloy and Cu are rolled into a composite strip through a rolling mill; the composite strip is thinned to 0.3~0.6mm, and the strip width is 9~ 12mm; the prepared composite strip is rolled into a U shape through a rolling mill; the U-shaped composite strip is rolled into an O shape after adding a drug core; the diameter is reduced to a diameter of 2.4-3.0mm; continue to reduce the diameter to make a diameter It is a composite solder flux-cored aluminum welding wire of 1.0-3.0mm. Among them, Cu accounts for 5% of the total weight of the solder, Si accounts for 10% of the total weight of the solder, Zn accounts for 6% of the total weight of the solder, a...

Embodiment 3

[0041] In the metal composite solder cored aluminum welding wire in the present embodiment, the outer skin is a metal composite solder, such as figure 2 As shown, the aluminum alloy layer 1 is Al-Si-Zn alloy, and the copper layer 2 is Cu. According to the thickness ratio of aluminum alloy layer: copper layer = 13:1, the Al-Si-Zn alloy and Cu are rolled into a composite strip through a rolling mill; the composite strip is thinned to 0.3~0.6mm, and the strip width is 9~ 12mm; the prepared composite strip is rolled into a U shape through a rolling mill; the U-shaped composite strip is rolled into an O shape after adding a drug core; the diameter is reduced to a diameter of 2.4-3.0mm; continue to reduce the diameter to make a diameter It is a composite solder flux-cored aluminum welding wire of 1.0-3.0mm. Among them, Cu accounts for 20% of the total weight of the solder, Si accounts for 10% of the total weight of the solder, Zn accounts for 5% of the total weight of the solder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com