Waste hydraulic pump dismantling line

A hydraulic pump and waste technology, which is applied in the field of waste hydraulic pump dismantling line, can solve the problems of unclamping, high surface accuracy and smoothness, and difficult compression, etc., and achieve the effect of improving dismantling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention and creation content, characteristics and effects of this patent, the following examples are exemplified, and detailed descriptions are as follows in conjunction with the accompanying drawings:

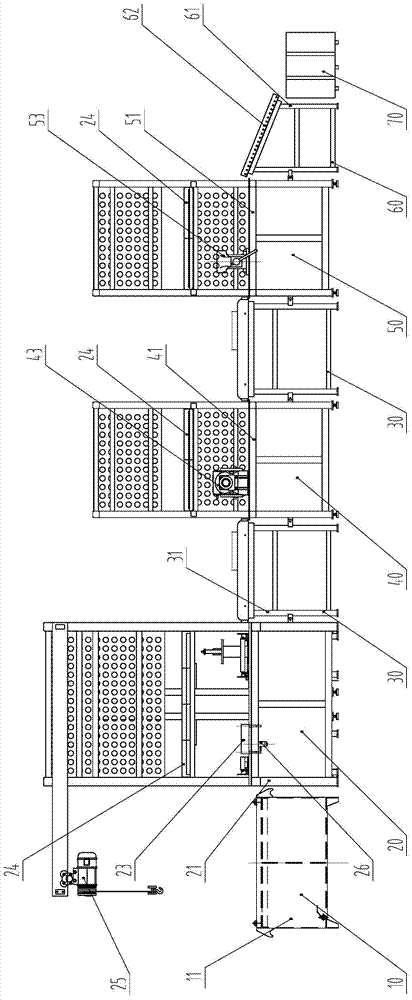

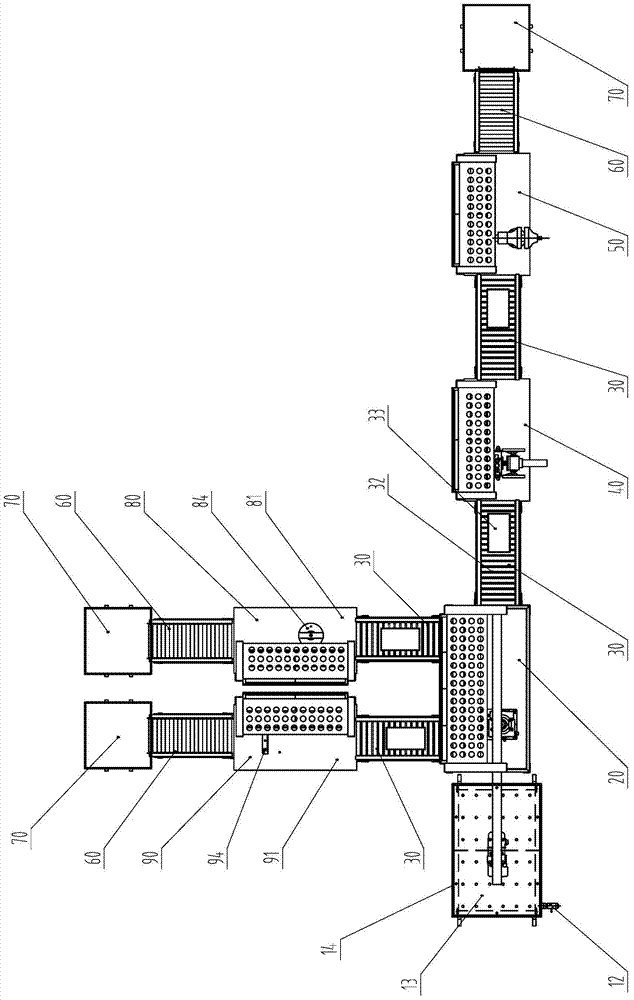

[0031] Such as figure 1 , 2 , 4, 5,

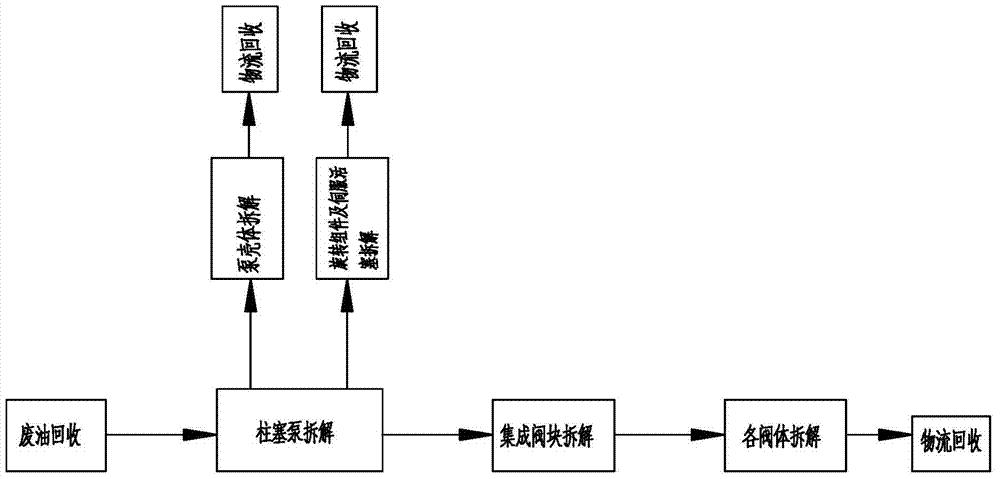

[0032] A waste hydraulic pump dismantling line, including a plunger pump dismantling station 20, the upstream of the plunger pump dismantling station is connected to a waste oil recovery device 10, and the plunger pump dismantling station is connected to an integrated valve through a parts transmission line 30 Block dismantling station 40, servo piston dismantling station 80, and pump shell dismantling station 90 are connected. The integrated valve block dismantling station is connected to the valve body dismantling station 50 through the parts transmission line. The bit is connected to the material recovery bin 70 through the material recovery transmission line 60 .

[0033] The waste oil re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com