Three-dimensional (3D) printing method of micro-nano structure based on near-field electrostatic spinning

A micro-nano structure and near-field electrostatic technology, which is applied in the field of micro-nano manufacturing and additive manufacturing, can solve the problems that it is difficult to manufacture three-dimensional solid parts and limit the popularization and application of 3D printing technology, so as to achieve low cost, improve forming accuracy, expand Effect of material selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] When preparing the liquid materials used in the preparation of micro-nano structures by the 3D printing method based on near-field electrospinning, take N,N-dimethylformamide and acetone at a volume ratio of 1:1, and N,N-dimethylformamide The mixture of methyl formamide and acetone press is used as a solvent, and polylactic acid-polyglycolic acid (PLGA) is dissolved in the solvent to form a PLGA solution with a mass fraction of 15%. When preparing micro-nano structures, the PLGA solution is used as a liquid material.

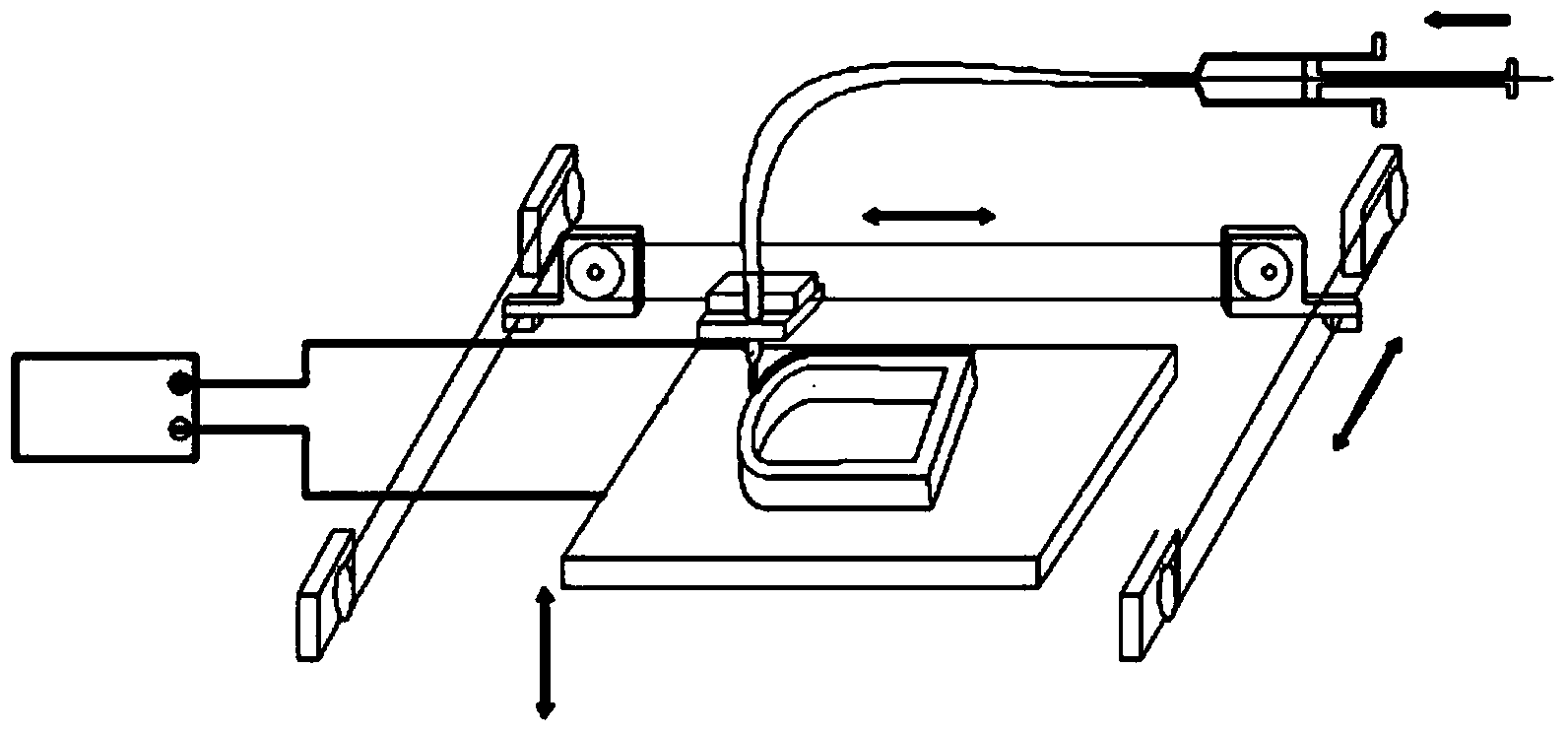

[0031] The 3D printing method of the micro-nano structure based on near-field electrospinning comprises the following steps:

[0032] 1) Use computer-aided design software to design a three-dimensional part model with a micro-nano structure, and then perform layered processing on the three-dimensional part model, with a layer thickness of 0.01mm, so as to form the contour data and filling data of each layered section of the three-dimensional part model ; ...

Embodiment 2

[0038] Isotactic polypropylene particles were heated and melted at 282 °C to prepare liquid materials required for a near-field electrospinning-based 3D printing method.

[0039] The 3D printing method of the micro-nano structure based on near-field electrospinning comprises the following steps:

[0040] 1) Use computer-aided design software to design a three-dimensional part model with a micro-nano structure, and then perform layered processing on the three-dimensional part model, with a layer thickness of 0.01mm, so as to obtain the contour data and filling data of each layered section of the three-dimensional part model ;

[0041] 2) Put the prepared liquid material into the precision extrusion syringe pump, heat the syringe pump to 282°C, control the extrusion speed of the liquid material to 0.4ml / h, and connect the extrusion nozzle to the positive pole of the DC high voltage generator , adjust the output voltage of the direct high-voltage generator to 0.5kV, and ground the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com