Light cotton fiber decorative panel and preparation method thereof

A cotton fiber and decorative panel technology is applied in the field of building materials to achieve the effects of low price, beautifying the ecological environment and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A preparation method for lightweight cotton fiber veneer, comprising the following steps:

[0022] (1) First mix epoxy resin glue and cotton fiber, and the mass ratio of epoxy resin glue is 30%;

[0023] (2) The mixed material is processed by air spinning process, and then the epoxy resin glue and cotton fiber mixed material are semi-cured or fully cured, and the heat curing temperature is 170o;

[0024] (3) After the curing treatment, the cotton fiber layer is subjected to a hot pressing process, and the melamine facing paper and the cotton fiber of the facing layer are formed into a board, wherein the hot pressing temperature is 180° to obtain a cotton fiber facing board.

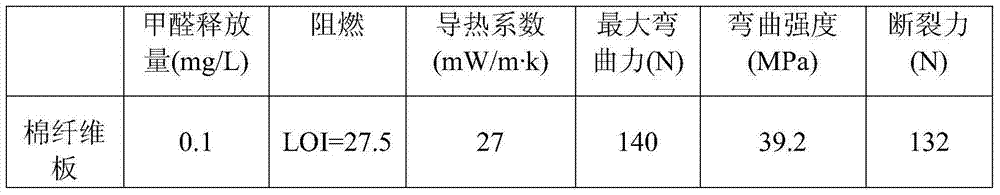

[0025] The performance parameters of cotton fiberboard are as follows:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com