A method for producing alumina from high-alumina fly ash

A high-alumina fly ash and alumina technology, which is applied in chemical instruments and methods, alumina/aluminum hydroxide, aluminum compounds, etc., can solve the uncertain process reliability, difficulty in large-scale equipment, and investment in acid process equipment High-level problems, to achieve the effect of reducing equipment and personnel investment, ensuring light-weight characteristics, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

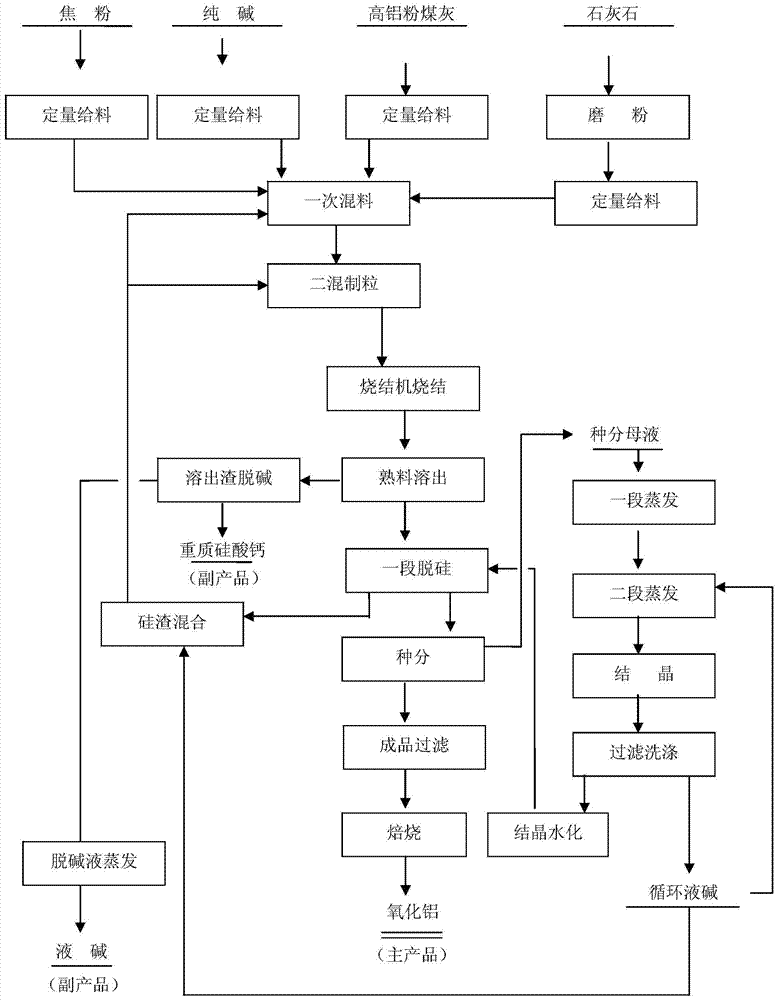

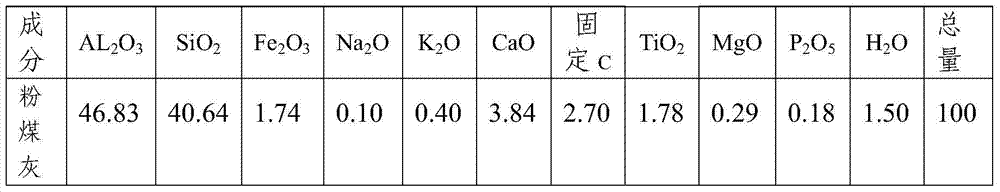

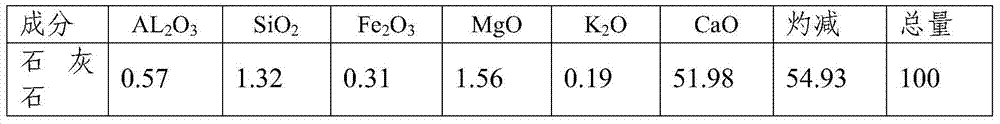

[0044] Process see figure 1 , Firstly crush the limestone with the composition shown in Table 2 to 2-5mm, then grind the ore powder to a particle size of -0.074mm accounting for more than 85%, and crush the coke powder to 1-3mm. Then add the fly ash and soda ash powder with ingredients as shown in Table 1 and mix thoroughly: 38 parts by weight of fly ash, 32 parts by weight of limestone, 20 parts by weight of soda ash, 8 parts by weight of coke powder, and then prepare lye (after two-step evaporation The circulating mother liquor of salt is divided into two parts, the distribution ratio is 87:13, and this step uses 87%), the concentration is Na2O 510g / L, and the causticization coefficient αk=14. The water content of the ingredients is 30%, the alkali ratio is 1, and the calcium ratio is 1.

[0045] Add the prepared materials together with 87% lye to the mixer for the first mixing. Once the mixed materials enter the secondary mixer, the remaining 13% lye is sprayed into the secon...

Embodiment 2

[0056] Firstly, the limestone with the composition shown in Table 2 is crushed to 2-5mm, then the ore powder is ground to a particle size of -0.074mm accounting for more than 85%, and the coke powder is crushed to 1-3mm. , Then add the fly ash and soda ash powder with ingredients as shown in Table 1 and mix thoroughly: 40 parts by weight of fly ash, 35 parts by weight of limestone, 22 parts by weight of soda ash, 10 parts by weight of coke powder, and then add lye, the concentration is Na2O550g / L, αk=20. The obtained ingredients have a moisture content of 28%, an alkali ratio of 1, and a calcium ratio of 1. The circulating mother liquor lye is divided into two parts by volume, the distribution ratio is 87:13, 87% of which is used for ingredients.

[0057] The prepared material is added to the mixer for the first mixing, and the mixed material enters the roller granulator, and at the same time, the remaining 13% lye is sprayed for granulation, and the particle distribution is 1-...

Embodiment 3

[0065] Firstly, the limestone with the composition shown in Table 2 is crushed to 2-5mm, then the ore powder is ground to a particle size of -0.074mm accounting for more than 85%, and the coke powder is crushed to 1-3mm. Then add the fly ash and soda ash powder as shown in Table 1 and mix thoroughly, 43 parts by weight of fly ash, 37 parts by weight of limestone, 25 parts by weight of soda ash, 12 parts by weight of coke powder, and then add the ingredients of lye, the concentration of lye is Na 2 O 600g / L, αk=30. The lye is divided into two parts by volume, and the distribution ratio is 87:13. The obtained ingredients have a moisture content of 26%, an alkali ratio of 1, a calcium ratio of 1, and a coke powder ratio of 12%.

[0066] The prepared material is added to the mixer for the first mixing, and the mixed material enters the roller granulator, and at the same time, the remaining 13% lye is sprayed for granulation, and the particle distribution is 1-8mm. The air permeabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com