High-hydrophilia polyvinyl chloride and preparation method thereof

A technology of polyvinyl chloride and hydrophilicity, which is applied in the chemical industry, can solve problems such as the limitation of the scope of use, and achieve the effects of improved hydrophilicity, excellent mechanical properties, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Test formula:

[0018] Formula material

Dosage (parts by weight)

PVC (medical grade)

100

Calcium Zinc Composite Stabilizer

3.3

Double 2-5 (initiator)

0.4-0.6

0.8-1.0

DOP (medical grade)

24

2.4

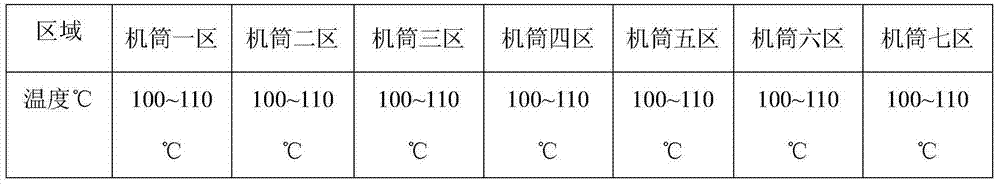

[0019] Stir PVC, stabilizer, initiator, lubricant, DOP and methacrylic acid in a high-speed mixer to 100 ° C, add to a twin-screw extruder for extrusion granulation, and the screw speed used for extrusion granulation is 80 -100 rpm; the temperature settings of the twin-screw extruder are shown in the table below:

[0020]

[0021] The obtained highly hydrophilic polyvinyl chloride has a contact angle of 96° as tested by a measuring instrument, while the contact angle of existing commercially available PVC is only 64°, and while the hydrophilicity of PVC of the present invention is significantly increased, other mechanical properties are uniform. The same...

Embodiment 2

[0023] Test formula:

[0024] Formula material

Dosage (parts by weight)

PVC (medical grade)

95

Calcium Zinc Composite Stabilizer

3.6

Double 2-5 (initiator)

0.4-0.6

0.8-1.0

DOP (medical grade)

28

2.8

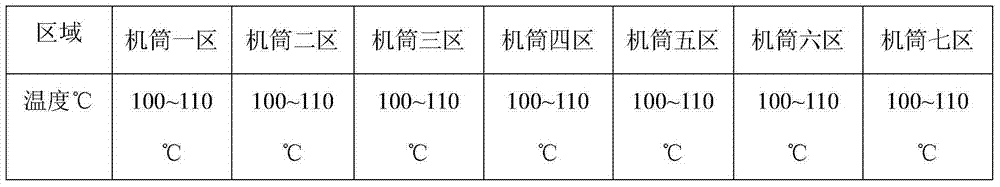

[0025] Stir PVC, stabilizer, initiator, lubricant, DOP and methacrylic acid in a high-speed mixer to 100 ° C, add to a twin-screw extruder for extrusion granulation, and the screw speed used for extrusion granulation is 80 -100 rpm; the temperature settings of the twin-screw extruder are shown in the table below:

[0026]

[0027] The obtained highly hydrophilic polyvinyl chloride has a contact angle of 95° as tested by a measuring instrument, while the contact angle of existing commercially available PVC is only 64°, and while the hydrophilicity of PVC of the present invention is significantly increased, other mechanical properties are all the same. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com