Simultaneous online measurement device for temperature, pressure and steam dryness of steam injection wells

A measuring device and pressure technology, which is applied in the field of steam injection oil well temperature, dryness online testing instrument and pressure field, can solve the problems of low efficiency, low detection accuracy, inapplicability, etc., and achieve low environmental requirements, simple measurement system, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

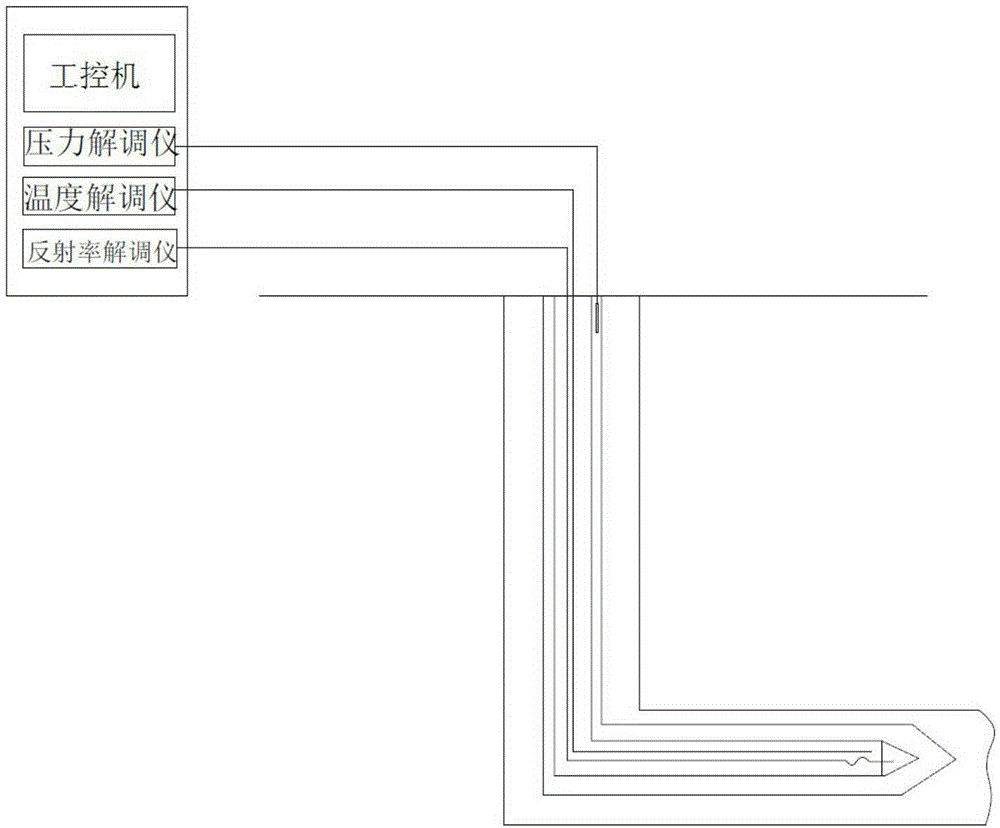

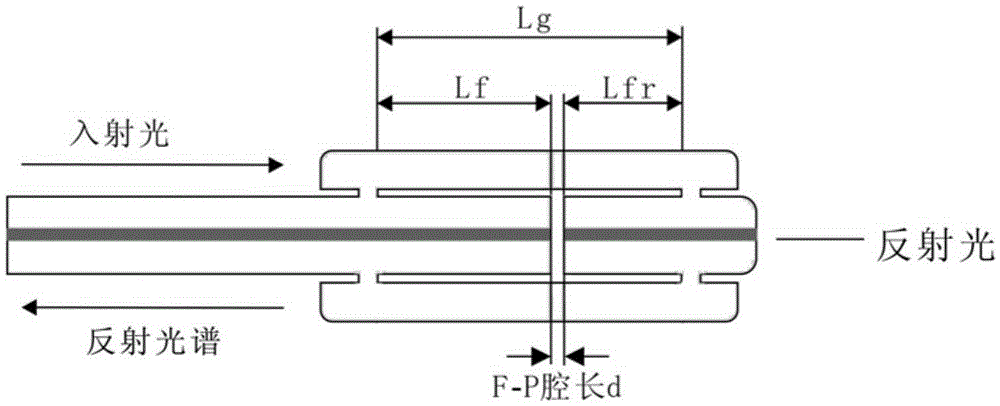

[0023] Such as figure 1 As shown, this online measuring device for temperature, pressure and dryness of steam injection well consists of temperature sensor, pressure sensor, reflectivity sensor, temperature demodulator, pressure demodulator, reflectivity demodulator, memory, industrial computer and downhole Probe composition.

[0024] The industrial computer includes a signal processor and a single-chip memory installed on the circuit board, and the circuit board and the power supply battery are installed in the chassis.

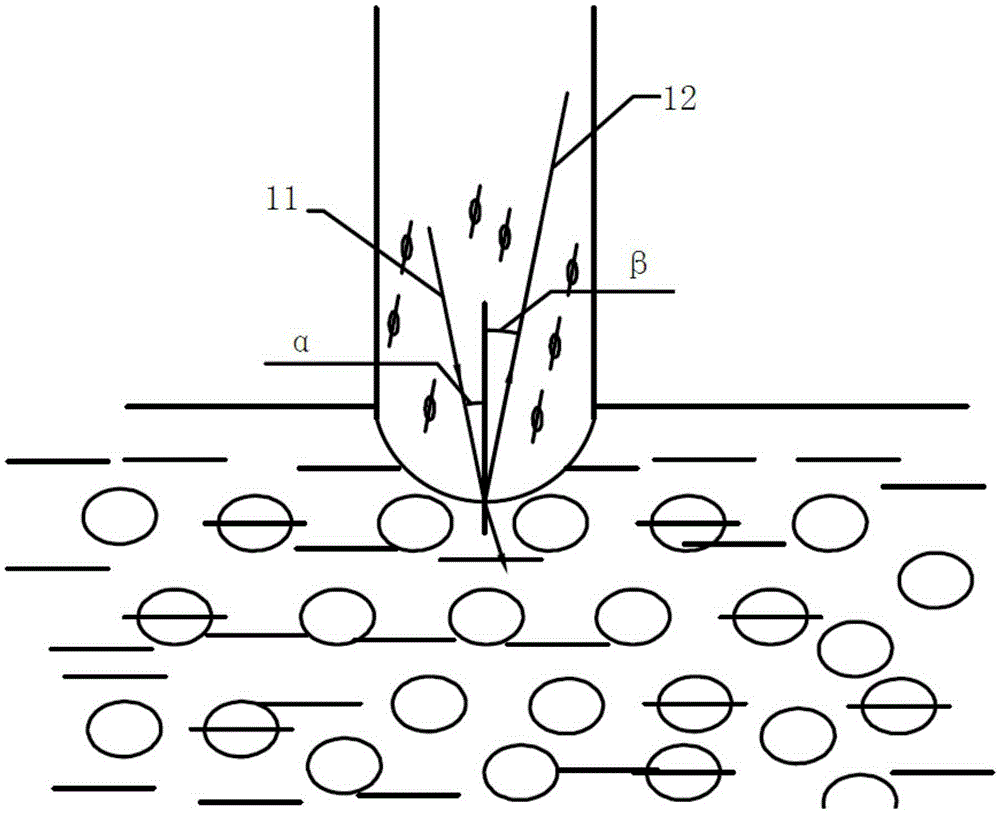

[0025] The downhole probe includes a casing and a closed cylinder arranged inside the casing. An annulus is formed between the casing and the closed casing, and diversion holes are provided on the casing wall. The annulus communicates with the outside of the downhole probe through the flow diversion holes; the casing and the closed casing The upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com