Uniform-screw-pitch pulp pump and impeller hydraulic design method of uniform-screw-pitch pulp pump

An equal-pitch, pulp pump technology, used in pumps, pump components, mechanical equipment, etc., can solve problems such as stuck, frequent cleaning, maintenance, impeller blockage, etc., to improve work efficiency, reduce winding or even stuck, and improve flow. effect of state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

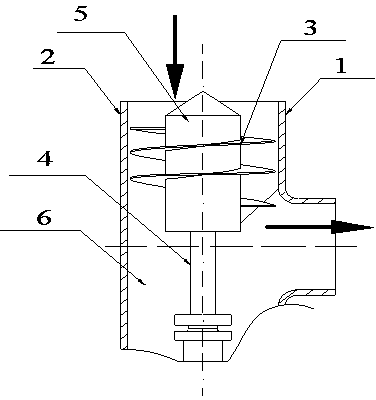

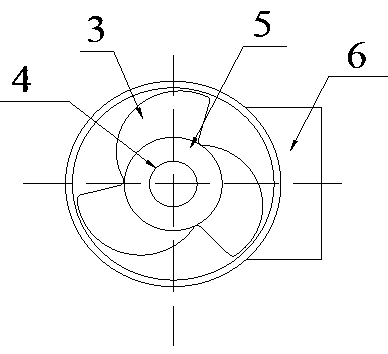

[0041] The structure of an equal-pitch pulp pump impeller proposed by the present invention is as follows: figure 1 shown; top view as figure 2 shown.

[0042] Design working condition flow rate Q=120m of the embodiment 3 / h, head H=30m, speed 1480r / min.

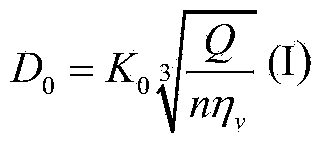

[0043] The present invention determines the impeller inlet equivalent diameter D by given the following relations 0 , Imported rim diameter D y1 , Imported hub ratio d h1 :

[0044] Determine the inlet diameter D of the impeller by formula (I), formula (II) and formula (III) j , outlet diameter D 2 , Blade outlet width b 2 :

[0045] D 0 = K 0 Q nη v ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com