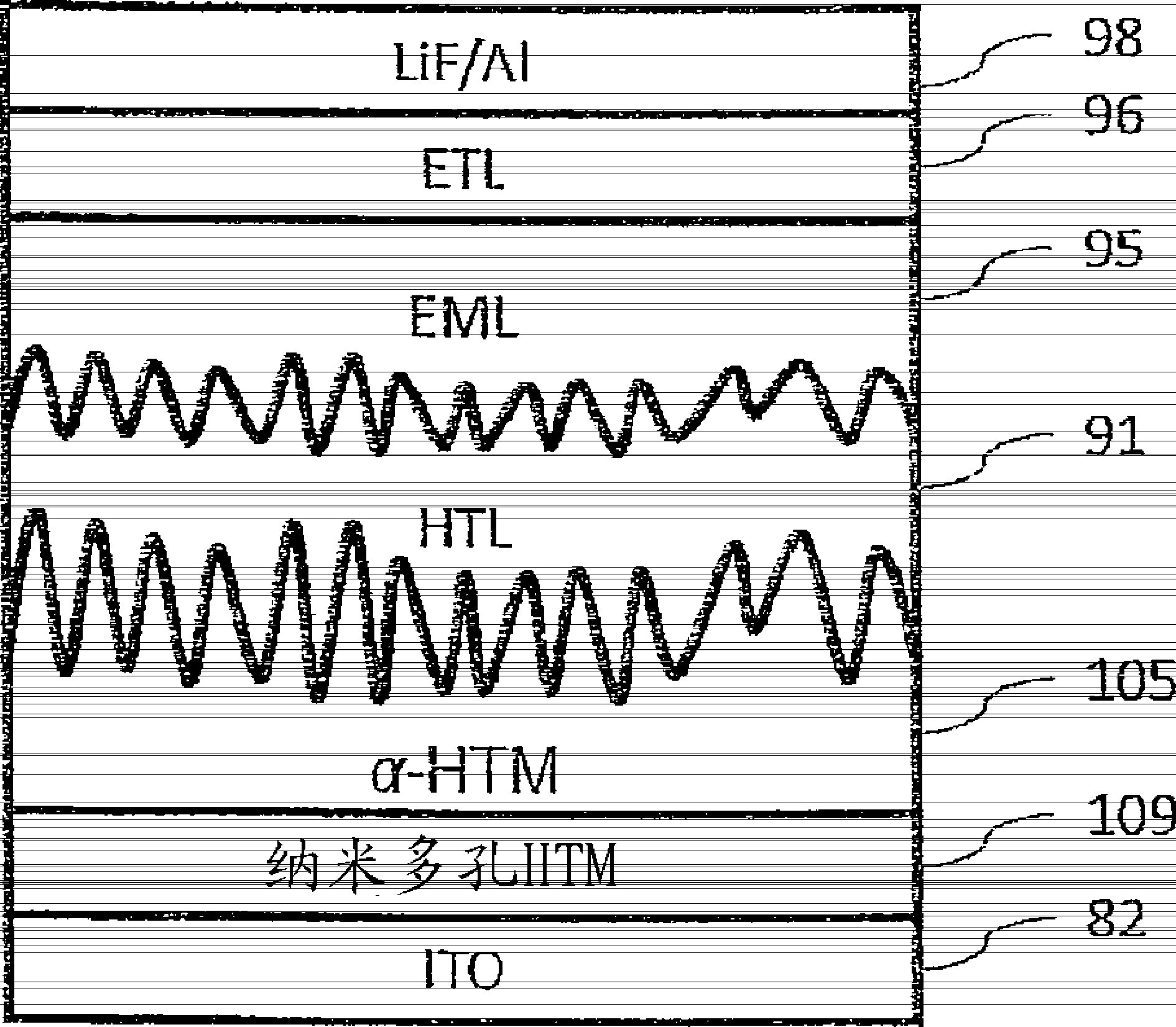

Materials and methods for OLED microcavities and buffer layers

A buffer layer and microcavity technology, applied in the field of materials and methods for OLED microcavity and buffer layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

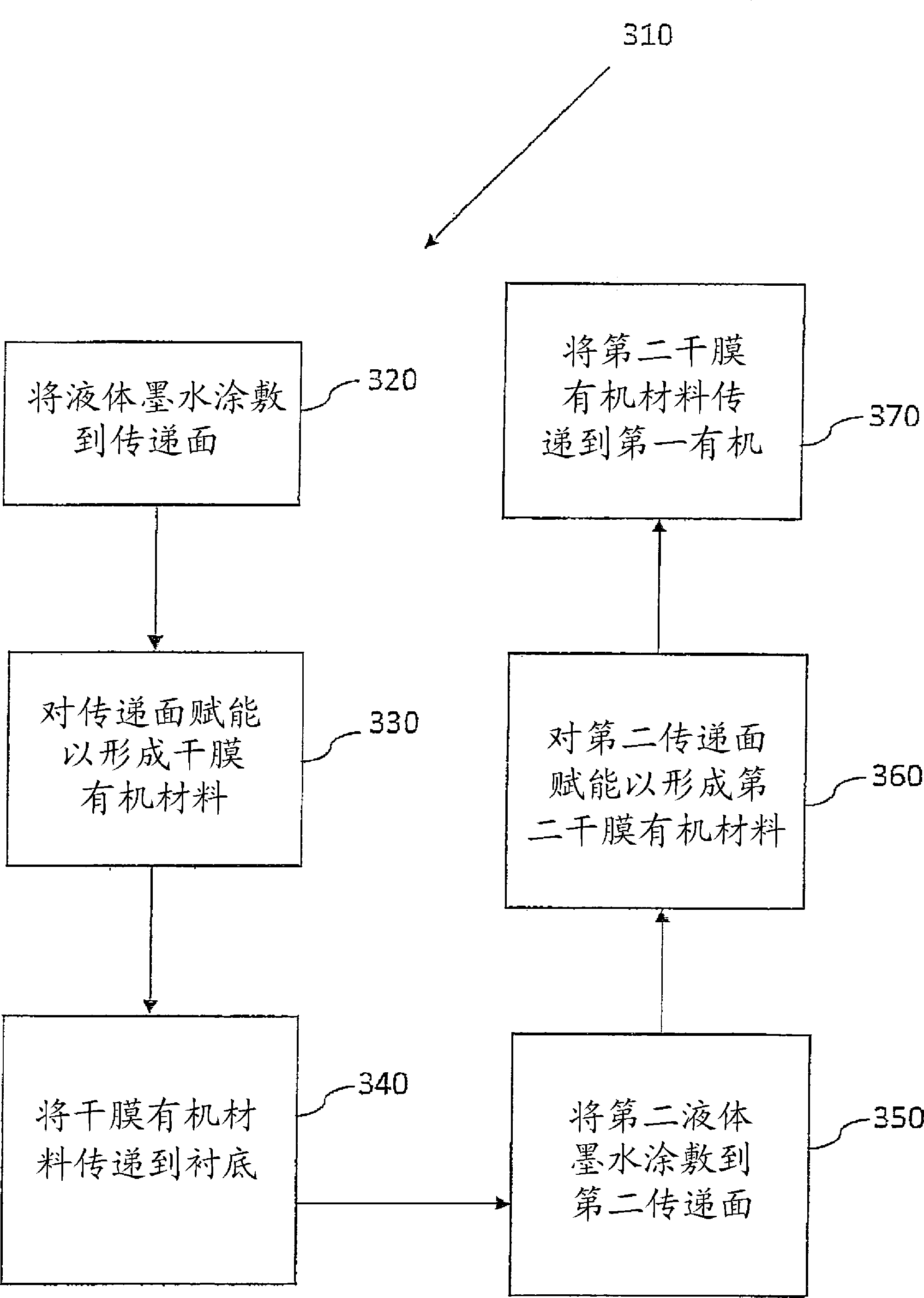

Method used

Image

Examples

example 1

[0142] This example demonstrates the functionality and excellent properties of the OLED component and the method of producing an OLED component according to the present teaching. For a 100 nm thick film, 2 drops of ink (approximately 12 picoliters) were applied at 1.2% ink concentration at 100 Hz. The loading temperature was 150°C. A vaporization temperature of about 250° C. is used over a period of time from about 200 milliseconds to about 1.0 seconds. The solids were then evaporated using a temperature ramp of 250°C - 380°C over a period of time from approximately 200 milliseconds to 800 milliseconds. A purge temperature of 350°C to 900°C is then used. The printing pitch is about 50 μm. The deposited film appeared hazy and had an AFM surface roughness greater than 5.0 nm. The printed film was post-baked at from about 150°C to about 200°C for from about 10 seconds to about 5.0 minutes on a hot plate in a nitrogen atmosphere. Atomic force microscopy (AFM) data confirmed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com