Soybeans without anti-nutritional factors and method for removing anti-nutritional factors of soybeans as well as application of soybeans

A technology of anti-nutritional factors and soybeans, which is applied in the fields of application, animal feed, animal feed, etc., can solve the problems of long processing cycle, high production cost, and poor removal effect of soybean antigen protein, so as to reduce feed deterioration, eliminate abuse, The effect of ensuring meat quality health and human food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

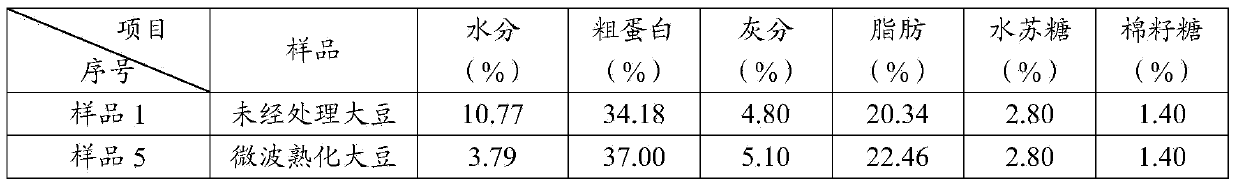

Embodiment 1

[0025] Clean up the soybean raw materials to remove the impurities mixed in the soybeans; spread the removed soybeans on the conveyor belt with a thickness of 1.5 cm and send them into the industrial microwave equipment, adjust the microwave frequency to 2815 MHz, and the microwave time to 11 minutes 25 seconds; crushing the microwave-cooked soybeans.

Embodiment 2

[0027] Clean up the soybean raw materials to remove the impurities mixed in the soybeans; spread the removed soybeans on the conveyor belt with a thickness of 1.4 cm and send them into the industrial microwave equipment, adjust the microwave frequency to 2780 MHz, and the microwave time to 11 minutes 15 seconds; crushing the microwave-cooked soybeans.

Embodiment 3

[0029] Clean up the soybean raw materials to remove the impurities mixed in the soybeans; spread the removed soybeans on the conveyor belt with a thickness of 1.7 cm and send them into the industrial microwave equipment, adjust the microwave frequency to 2850 MHz, and the microwave time to 11 minutes 36 seconds; crushing the microwave-cooked soybeans.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com