Electrical tar precipitator

A technology of an electric tar catcher and a feeding box is applied in the field of electric tar catcher, and can solve the problems of explosion of the electric tar catcher, safety production accident, and it can only be installed outdoors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

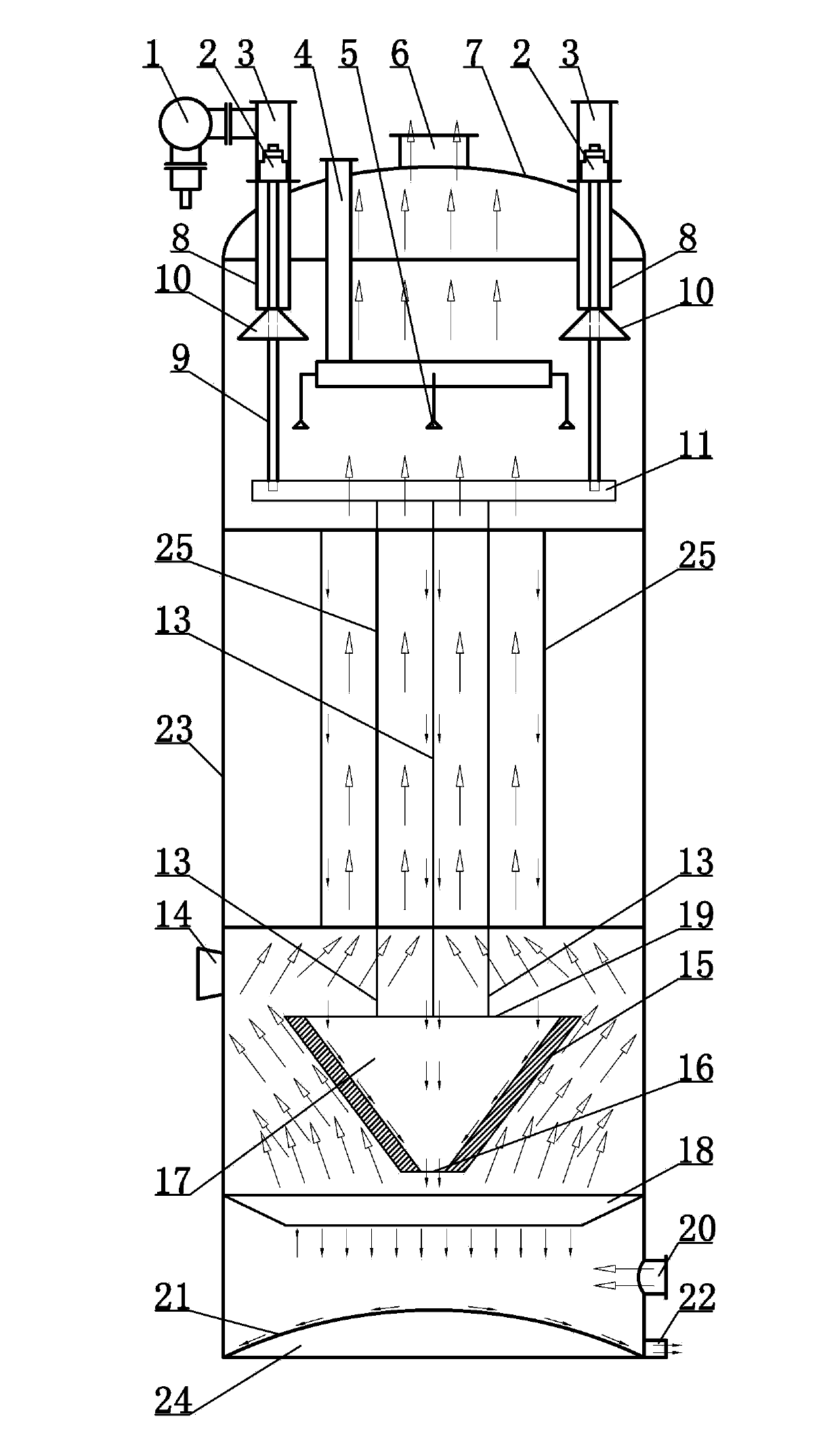

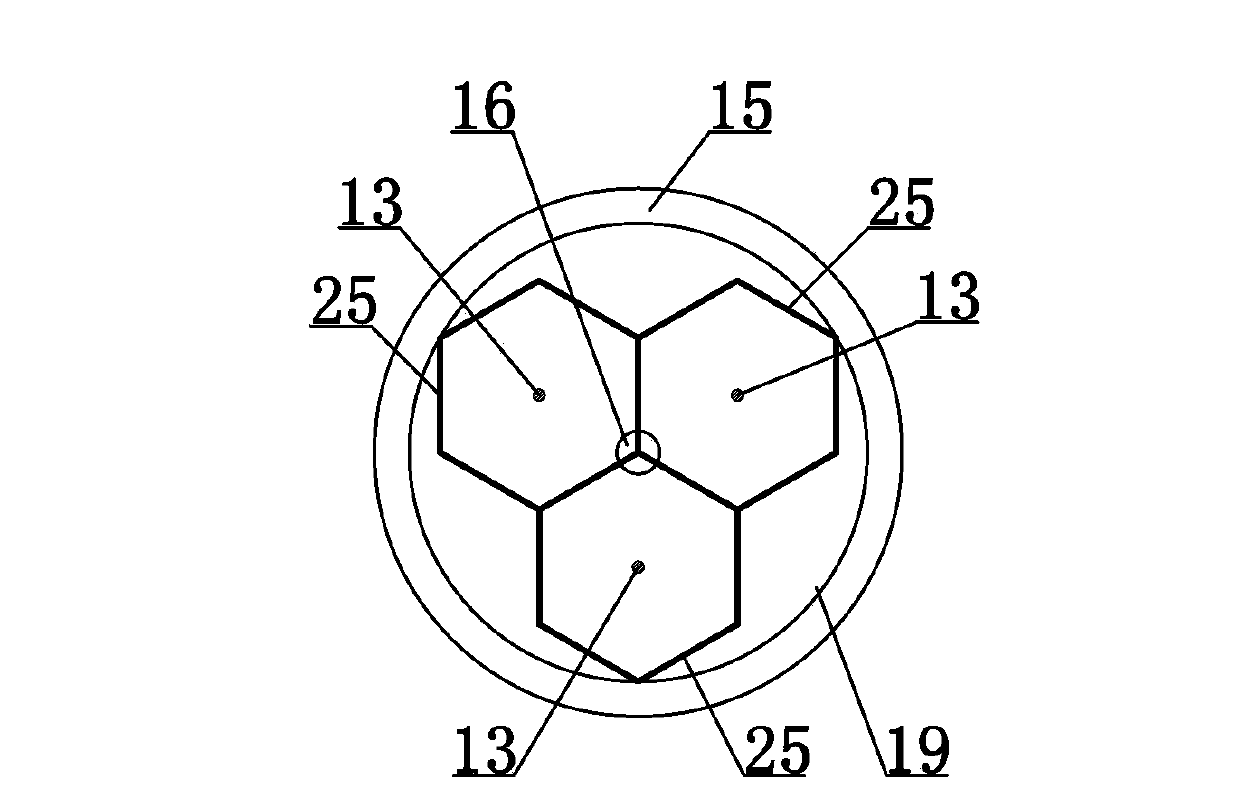

[0009] An electric tar catcher, such as figure 1 , figure 2 As shown, it includes a vertical cylinder 23, a head 7, a feeder box 1, an insulating box 3, an insulating porcelain bottle 2, a suspender 9, a protective tube 8, a spray device, a gas choke 10, a suspension frame 11, and a honeycomb Precipitator tube body 12, corona wire 13, gas distribution plate 18 and convex bottom 24, spray device has spray water inlet pipe 4 and spray head 5, honeycomb precipitate tube body 12 is composed of hexagonal rib tube 25, the orthographic shape of each hexagonal ribbed tube 25 along its length direction is hexagonal and its peripheral wall has six rectangular plane walls, and two adjacent hexagonal ribbed tubes 25 have the same rectangular plane wall , the gas distribution plate 18 itself is provided with dispersed diversion holes through the plate body, the upper end of the vertical cylinder 23 is fixed with a head 7 that closes the upper end of the mouth, and the wall of the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com