Polysilicon production apparatus

A production device, polysilicon technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of long adjustment process time, pollution of silicon rods, etc., to reduce the production of silicon powder, reduce the waste of raw materials, and improve the productivity of silicon rods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

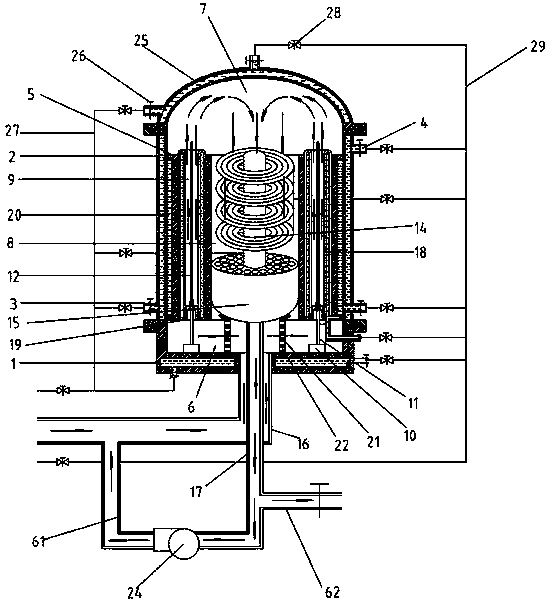

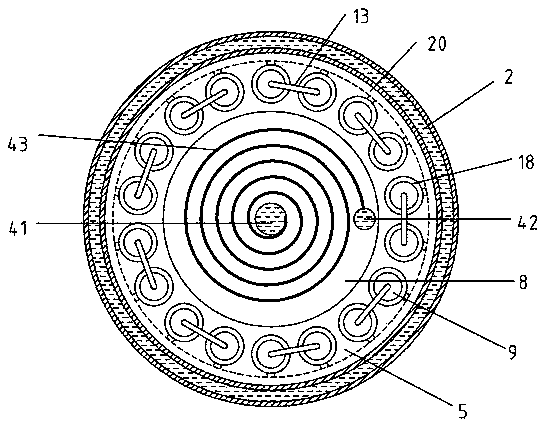

[0021] like figure 1 and figure 2A kind of polycrystalline silicon production device shown, comprises chassis 1 and bell jar 2, and bell jar 2 upper end is opened, and the upper end of bell jar 2 is provided with sealing head 25, and the flange connection between sealing head 25 and bell jar 2, chassis 1, Both the bell jar 2 and the sealing head 25 are double-layer structures, and a gap for cooling liquid flow is provided between the double layers. The chassis, the bell jar, and the sealing head are respectively provided with a cooling liquid inlet 3 and a cooling liquid connected to the cooling liquid flow gap. Coolant outlet 4, each coolant inlet 3 and coolant outlet 4 are provided with a manual valve 26, each coolant inlet 3 is connected with a separate pipe and coolant input pipe 27, and each coolant outlet 4 is also passed The pipes are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com