Seawater desalination system and method with variable load reverse osmosis

A technology of reverse osmosis and variable load, applied in the direction of osmosis/dialysis water/sewage treatment, seawater treatment, general water supply saving, etc., can solve the problems of inability to maintain stable water production, poor versatility, etc., achieve wide application range, reduce water production Energy consumption and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

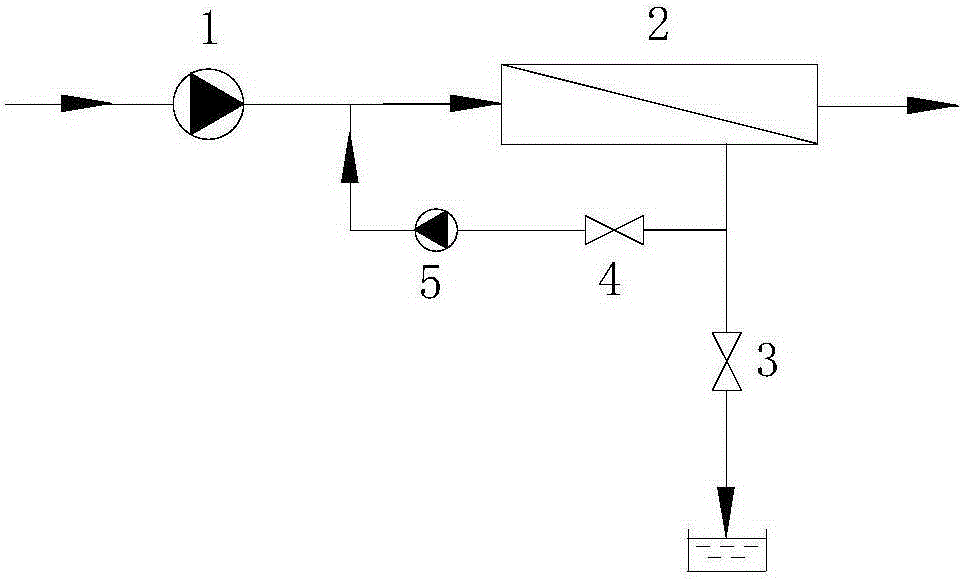

[0029] Such as figure 1 As shown (the controller and frequency converter are not shown in the figure), the water production is 50m 3 / d, the RO system with a recovery rate of 40% is an example. The concentrated brine pipeline of RO membrane group 2 is divided into two branches, one branch is the concentrated brine discharge pipeline, and the other branch is the concentrated brine return pipeline. A discharge valve 3 and a return valve 4 are respectively arranged on the concentrated brine discharge pipeline and the return pipeline to control the flow of the concentrated brine. At the same time, a booster pump 5 is arranged behind the return valve 4 on the concentrated brine return pipeline, so that the returned concentrated brine is delivered to the water inlet pipeline of the RO membrane group 2 . When the RO system is in normal operation, the inflow flow is 10.5m 3 / h, the return valve 4 is closed, and the opening of the discharge valve 3 is controlled so that the discharg...

Embodiment 2

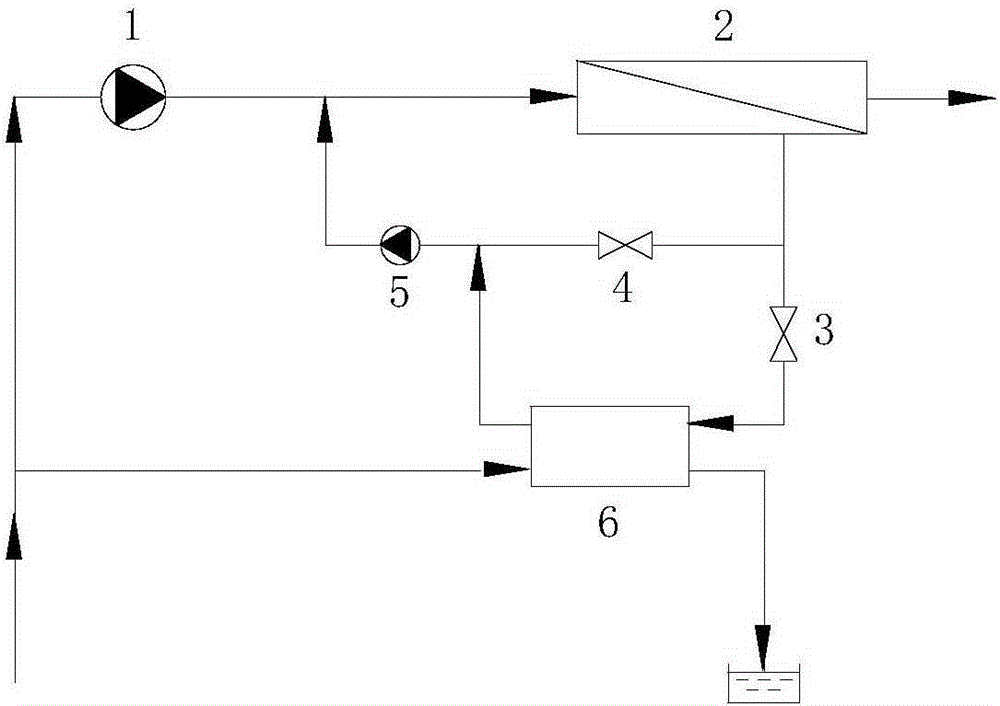

[0032] Such as figure 2 As shown, the water production is 50m 3 / d, the RO system with energy recovery device 6 with a recovery rate of 40% is taken as an example. and figure 1 The difference in the process is that an energy recovery device 6 is added to the RO system. When the RO system is in normal operation, all the concentrated brine of the RO membrane group 2 enters the energy recovery device 6 through the discharge valve 3, and the hydraulic energy of the concentrated brine is converted into the hydraulic energy of the original seawater before being discharged; at the same time, 60% of the original seawater enters the energy recovery device 6. After the recovery device 6 obtains hydraulic energy, it is delivered to the water inlet pipeline of the RO membrane group 2 through the booster pump 5, and 40% of the raw seawater is delivered to the water inlet pipeline of the RO membrane group 2 through the high-pressure pump 1. When the output power of the wind power and so...

Embodiment 3

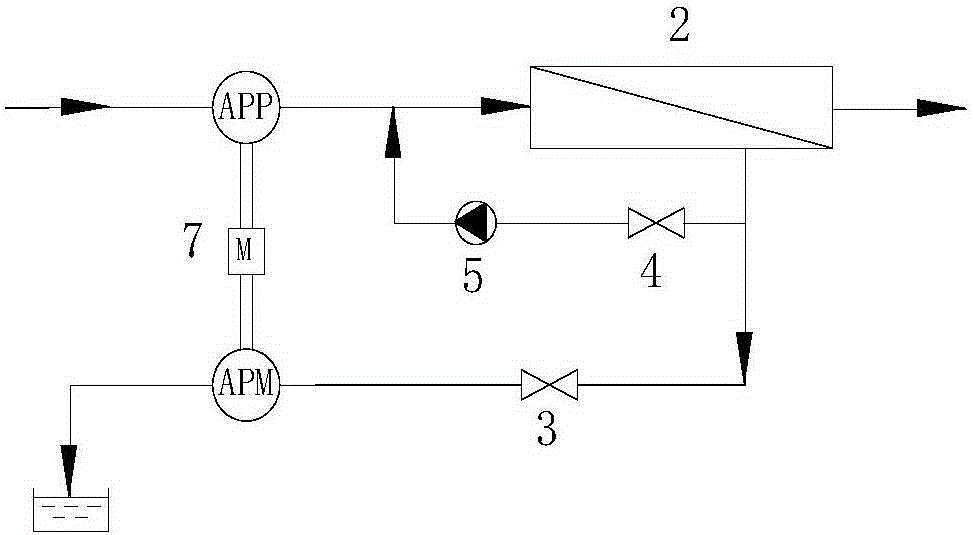

[0034] Such as image 3 As shown, the water production rate is 5m 3 / d, RO system with SWPE7 with 29% recovery as an example. and figure 1 The difference in the process is that SWPE7 is added to the RO system. SWPE7 is composed of an APP pump and an APM engine connected to the coaxial motor. It is realized by allowing the concentrated brine from the RO membrane group 2 to enter the APM engine to convert high-pressure water energy into mechanical energy for reuse by the motor. . When the RO system is in normal operation, the raw seawater enters the RO membrane group 2 through the APP pump, and all the concentrated brine of the RO membrane group 2 enters the APM through the discharge valve 3 to recover energy and then discharge. Since the displacement of APM is fixed, the recovery rate is also fixed. The SWPE7 used in this RO system has a maximum water flow of 1.05m 3 / h. When the output power of the wind power and solar power generation system is lower than the operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com