A molten salt steam generating system capable of variable load operation within the full parameter range

A generation system and full-parameter technology, applied in the steam generation method using heat carrier, steam engine device, solar heating system, etc., can solve the problems of slow flow rate, no sewage design, high control requirements, etc., to increase water side convective heat transfer coefficient, prevention of scale formation, effect of compact system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

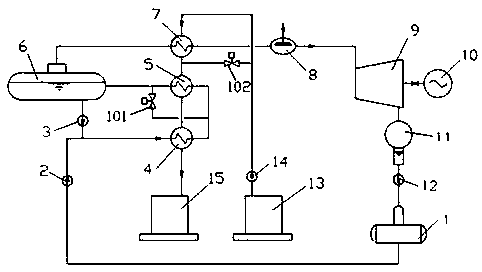

[0039] This embodiment provides a molten salt steam generating system capable of variable load operation within the full parameter range, such as figure 1 shown, which includes:

[0040] Deaerator 1, feed water pump 2, preheater 4, evaporator 5, steam drum 6, superheater 7, hot brine tank 12, hot brine pump 14 and cold brine tank 15; among them, the hydraulic fluid passes through the deaerator in sequence Oxygenator 1, feed water pump 2, preheater 4, evaporator 5, steam drum 6 and superheater 7; molten salt working medium passes through hot salt tank 13, hot salt pump 14, superheater 7, evaporator 5, Preheater 4 and cold brine tank 15;

[0041] The hydraulic medium and the molten salt working medium gradually exchange heat in the preheater 4, evaporator 5 and superheater 7 to generate superheated steam. The superheated steam enters the water spray desuperheater 8 for water spray desuperheating and then flows into the steam turbine 9 and drives The steam turbine 9 works, and ...

Embodiment 2

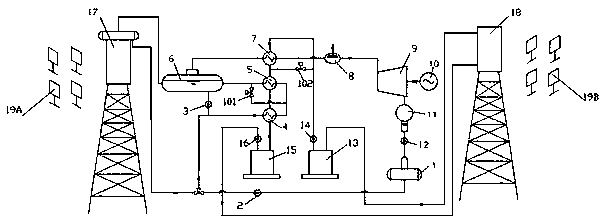

[0051] This embodiment provides a molten salt steam generating system capable of variable load operation within the full parameter range, such as figure 2 shown, which includes:

[0052] Deaerator 1, feed water pump 2, preheater 4, evaporator 5, steam drum 6, superheater 7, hot brine tank 12, hot brine pump 14 and cold brine tank 15; among them, the hydraulic fluid passes through the deaerator in sequence Oxygenator 1, feed water pump 2, preheater 4, evaporator 5, steam drum 6 and superheater 7; molten salt working medium passes through hot salt tank 13, hot salt pump 14, superheater 7, evaporator 5, Preheater 4 and cold brine tank 15;

[0053] The hydraulic medium and the molten salt working medium gradually exchange heat in the preheater 4, evaporator 5 and superheater 7 to generate superheated steam. The superheated steam enters the water spray desuperheater 8 for water spray desuperheating and then flows into the steam turbine 9 and drives The steam turbine 9 works, and...

Embodiment 3

[0067] Such as figure 2As shown, a tower-type solar thermal power generation system capable of variable load operation within the full parameter range, the system includes deaerator 1, feed water pump 2, molten salt steam generation system, steam turbine 9, generator 10, condensing steam 11, condensate water pump 12, hot salt tank 13, hot salt pump 14, cold salt tank 15, cold salt pump 16, water heat absorber 17, molten salt heat absorber 18, No. 1 mirror field 19A, No. 2 mirror Field 19B and interconnected pipes. Among them, the molten salt steam generation system also includes a circulating pump 3, a preheater 4, an evaporator 5, a steam drum 6, a superheater 7, a water spray desuperheater 8, an evaporator bypass regulating valve 101 and a hot salt distribution regulating valve 102.

[0068] When there is no cloud above the heliostat mirror field, the water deoxidized by the deaerator 1 enters the water heat absorber 17 at the top of the heat absorption tower after the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com