A kind of particle reinforced aluminum matrix composite material and preparation method thereof

A particle-reinforced aluminum and composite material technology is applied in the design and preparation of aluminum-based composite materials and new particle-reinforced aluminum-based composite materials, which can solve the problems of high melting point, good thermal conductivity and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 2vol.% (Al 2 o 3 +MgO·Al 2 o 3 ) Preparation and Mechanical Properties of Particle Reinforced ZL101 Aluminum Matrix Composites

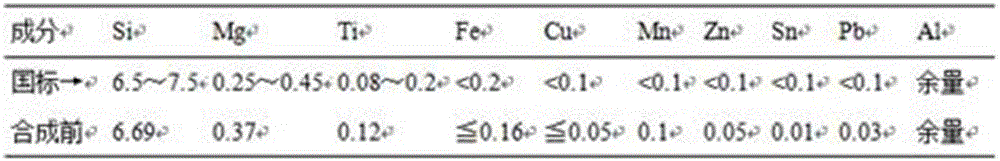

[0022] The main components of ZL101A are listed in Table 1.

[0023] Table 1 Chemical composition (wt%) of ZL101 aluminum alloy

[0024]

[0025] With MgO and SiO 2 As a reactant, the total volume fraction of target reinforcing particles is 2vol.%, and the simple compound Al is expected to be generated 2 o 3 Volume fraction 1vol.%, complex compound MgO Al 2 o 3 (Magnesium-aluminum spinel) volume fraction 1vol.%, the initial aluminum amount is 2kg, you need to add 5g of MgO, SiO 2 The amount is 29.56g, and the reactant powder is 34.56g in total.

[0026] The preparation process is as follows: cool the baked reactants and mix them evenly, divide 34.56g of reactants into two packages according to the amount of 20g~21g per package, wrap them with aluminum foil for use; melt ZL101 aluminum alloy in a crucible furnace , when ...

Embodiment 2

[0027] Example 2 4vol.% (Al 2 o 3 +MgO·Al 2 o 3 ) Preparation and Mechanical Properties of Particle Reinforced ZL101 Aluminum Matrix Composites

[0028] With MgO and SiO 2 +TiO 2 As a reactant, the total volume fraction of target reinforcement particles is 4vol.%, and the simple compound Al is expected to be generated 2 o 3 Volume fraction 2vol.%, and complex compound MgO·Al 2 o 3 (Magnesium-aluminum spinel) volume fraction 2vol.%, initial aluminum amount is 2kg, then need to add MgO amount 10g, SiO 2 Quantity 29.56g, TiO 2 The amount was 39.41 g, and the reactant powder was 78.97 g in total.

[0029] The preparation process is as follows: cool the baked reactants and mix them evenly, divide 78.97g of reactants into three packages according to the amount of 23g~27g per package, wrap them with aluminum foil for use; melt ZL101 aluminum alloy in a crucible furnace , when the temperature reaches 850°C, use a graphite bell jar to press the powder packets into the melt o...

Embodiment 3

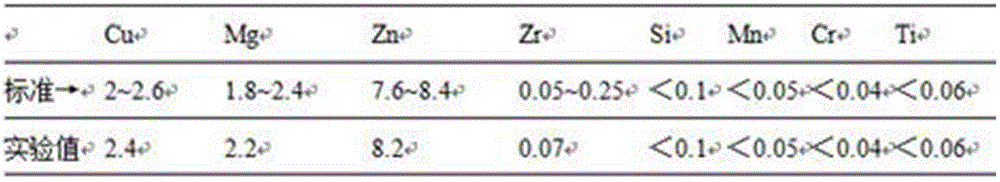

[0030] Example 3 3vol.% (Al 2 o 3 +MgO·Al 2 o 3 ) Preparation and mechanical properties of particle-reinforced 7055 aluminum matrix composites The composition of 7055 aluminum alloy is shown in Table 2.

[0031] Table 2 Composition list of 7055 aluminum alloy

[0032]

[0033] With MgO and ZrO 2 As a reactant, the total volume fraction of target reinforcing particles is 3vol.%, and the simple compound Al produced 2 o 3 Volume fraction 1.5vol.%, and complex compound MgO·Al 2 o 3 (Magnesium-aluminum spinel) volume fraction 1.5vol.%, the initial aluminum content is 1kg, the amount of MgO added is 7.5g, ZrO 2 The amount is 90.9g, and the total amount of reactants is 98.4g.

[0034] The preparation process is as follows: cool the baked reactants and mix them evenly, divide 98.4g of reactants into four packages according to the amount of 20g~30g per package, wrap them with aluminum foil for use; melt 7055 aluminum alloy in a crucible furnace , when the temperature reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com