High-breathability yarn and manufacturing method thereof

A manufacturing method and yarn technology, applied in the direction of yarn, textile and papermaking, filament/thread forming, etc., can solve problems such as the inability to match the drying speed of clothing, the unsatisfactory perspiration effect of fabrics, and the unsatisfactory ventilation effect. , to achieve the effect of enhancing moisture absorption, increasing wearing comfort, and low unit price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

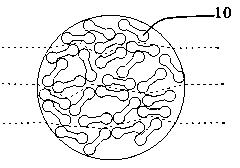

[0015] The air-permeable knitted fabric of the present invention is woven from polyester special-shaped cross-section yarns, see figure 1 , the polyester special-shaped cross-section yarn is composed of dumbbell-shaped 75D / 22F fibers 10 .

[0016] Because the cross-section of the fibers that make up the yarn has undergone a change in physical form, from the existing cylindrical shape to a dumbbell shape, this structure makes the yarn have more gaps, and the gap between the fibers increases, which is conducive to air circulation and enhances the strength of the yarn. Improve the moisture volatility of the fabric, so that the fabric can evaporate sweat more quickly, thereby enhancing the breathability of the fabric;

[0017] The fiber has a larger cross-sectional area to enhance the siphon effect of the fabric, thereby enhancing the moisture abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com