Stability augmentation and solidification method for large-section water-rich saturation fine-silt railway tunnel

A technology with fine sand and large cross-section, which is applied in the field of reinforcement and consolidation of large cross-section water-rich and saturated fine sand railway tunnels. It can solve problems such as shotcrete cracking, open welding of steel frames and longitudinal connecting bars, and uneven convergence deformation. Achieve the effect of ensuring construction safety, improving overall stability and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

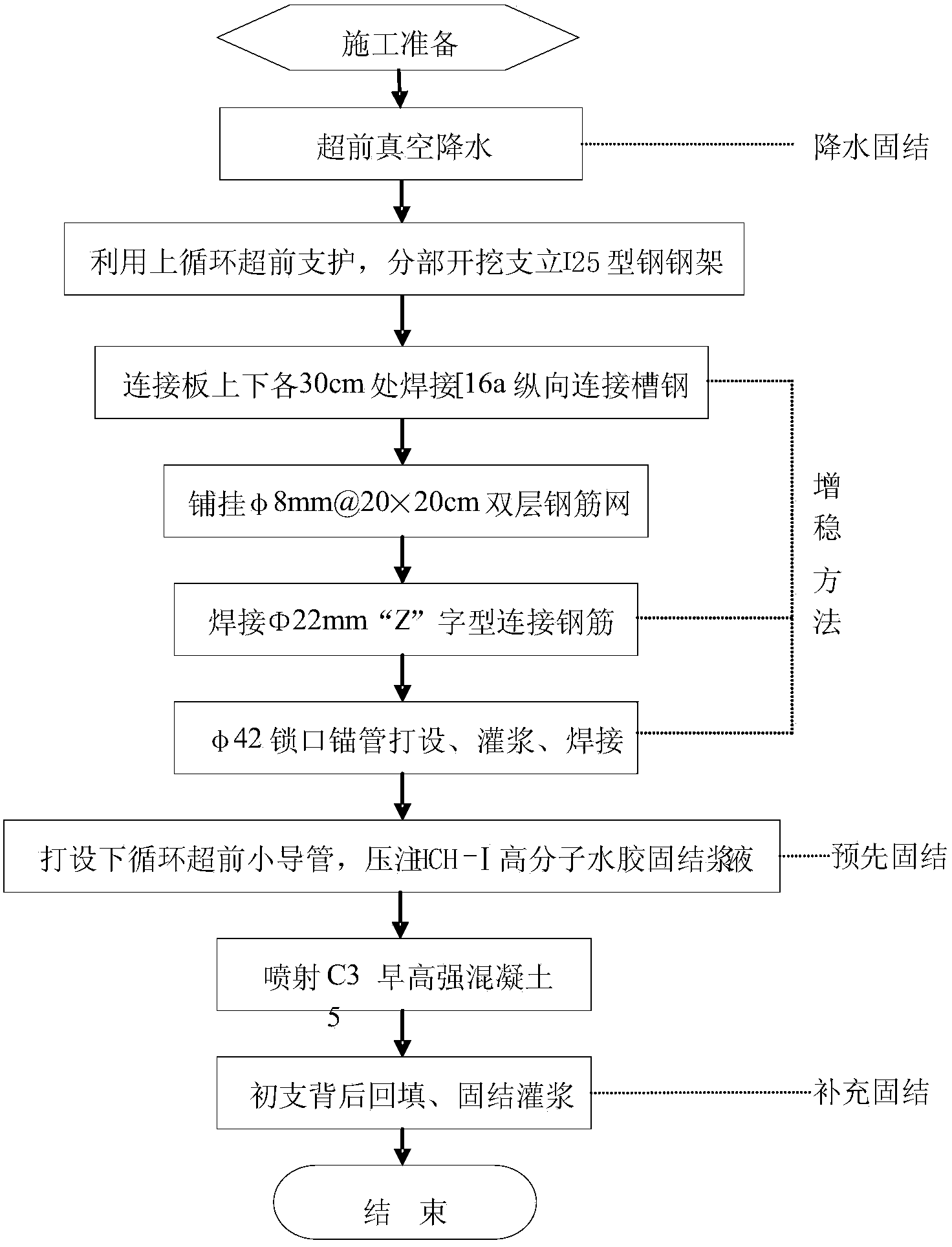

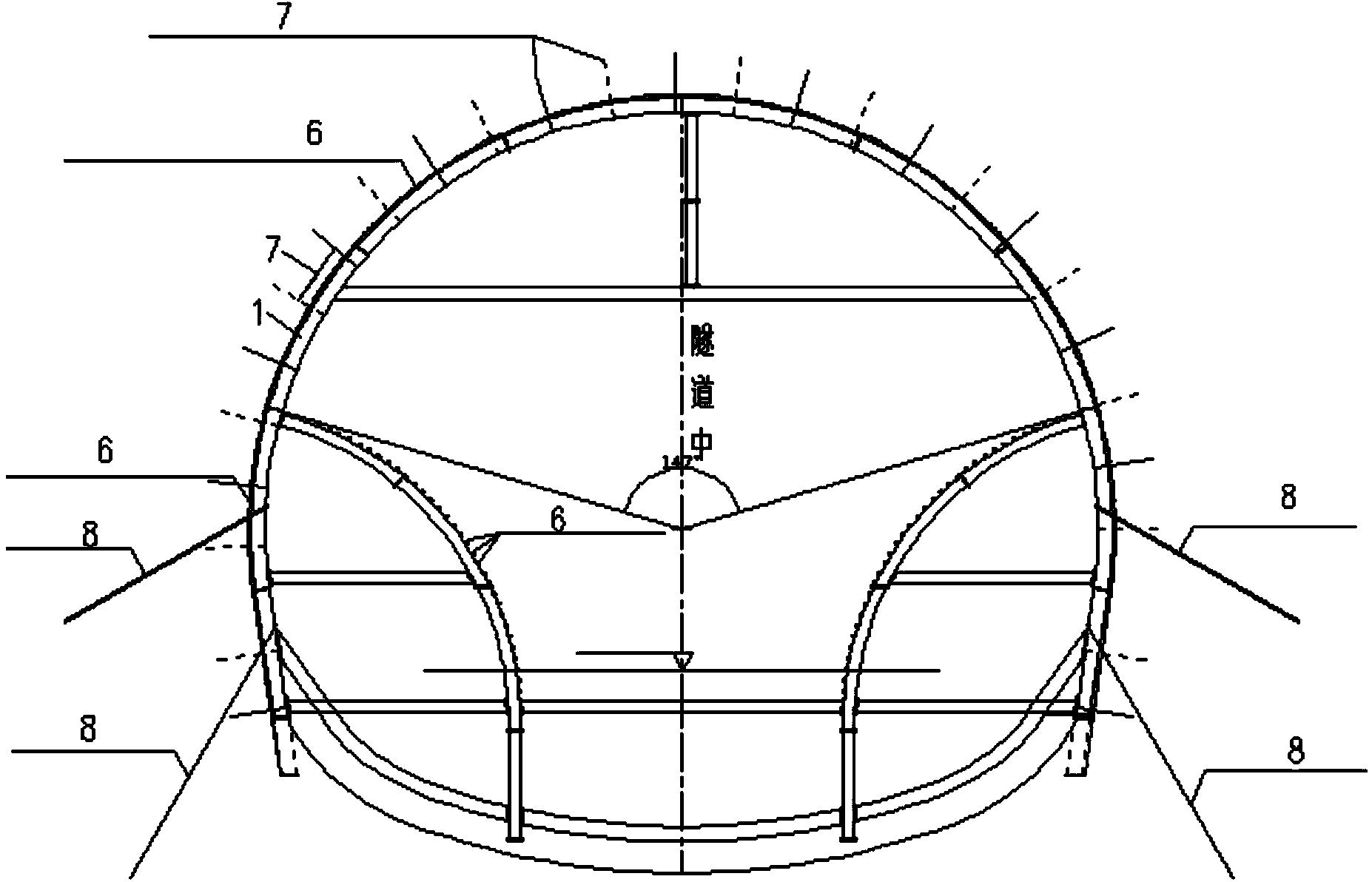

[0036] Such as figure 1 Shown: a method for increasing the stability of a large-section water-rich saturated silt-fine sand railway tunnel, including the following steps:

[0037] 1. Precipitation in advance: use the 5.3m-high double-side wall pilot tunnel to construct the lower half section of the front tunnel ahead of time, adopt the method of "vacuum light well point dewatering + filter sump pit collection and drainage", the length of φ32mm PPR tube well is 4-5m, and V6 is selected A type vacuum pump (7.5KW) carries out advanced drainage of the pilot tunnel in steps, and the vacuum dewatering main pipe guides and drains the water to the filter sump for centralized pumping and drainage. According to the construction summary of the field test section, the precipitation effect should satisfy the fact that the sand layer is slightly wet but no clear water seepage is the best when the face is excavated. At this time, the measured moisture content of the sand is 5-8%. The above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com