Floating type double-layer back plate brake pad

A brake pad, floating technology, applied in the direction of brake parts, etc., can solve the problems of not being able to obtain the maximum effective friction area, the service life of the brake pad, and the uneven braking pressure, etc., to achieve simple structure, reduce noise, The effect of equalizing brake pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

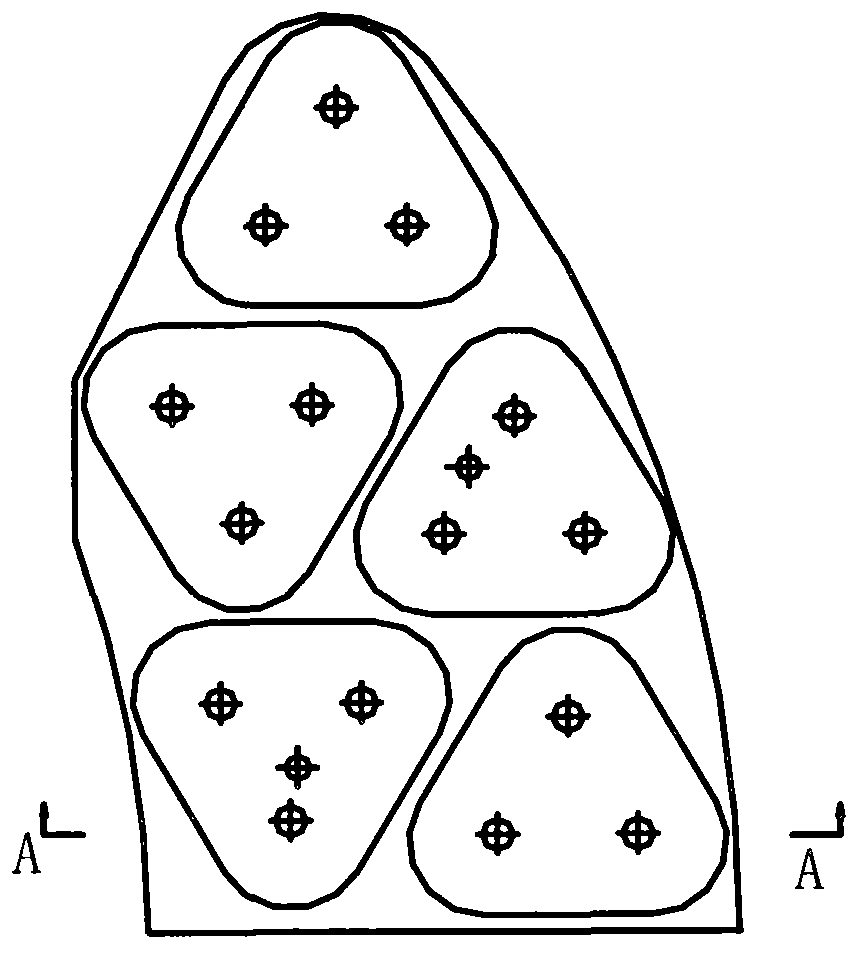

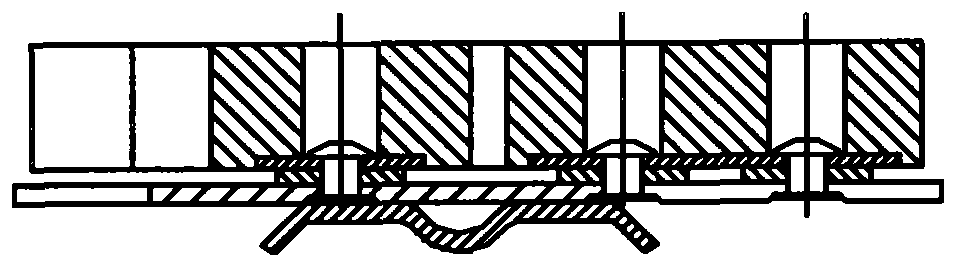

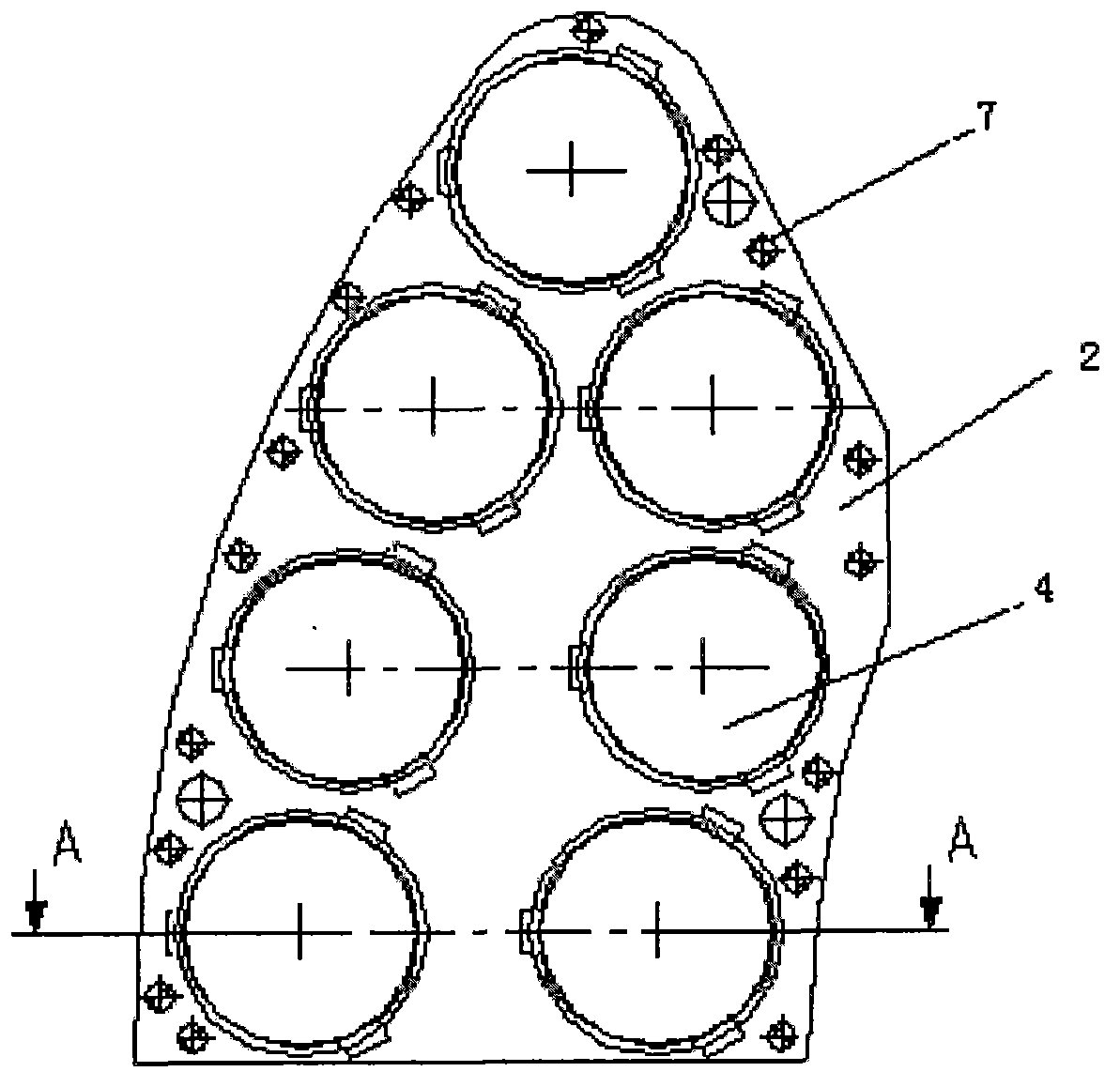

[0033] Such as Figure 3-6 As shown, the present invention includes a brake pad thick back plate 1, a brake pad thin back plate 2, several elastic pads 3, several brake pad friction blocks 4, a dovetail 5, several rivets 6, and several electric welding points 7.

[0034] Such as Figure 7-8 As shown, the arc-shaped sole structure of the thick back plate 1 of the brake pad of the present invention is made of steel material. The installation hole 102 of the brake pad friction block 2, the through hole 103 through which the guide and fastening connector of the brake pad friction block 2 passes, and the positioning hole 104 for realizing installation and positioning with the thin back plate 2.

[0035] Such as Figure 9-10 As shown, the elastic pad 3 of the present invention is stamped and formed from a high-temperature resistant alloy stainless spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com