Pipeline nonstop-transmission holing and plugging system and process method thereof

A technology for pipelines and drilling machines, which is applied to chemical instruments and methods, cleaning methods and appliances, pipe components, etc., and can solve the problem of inability to seal the sealing operation surface tightly, damage to gas polyethylene pipelines, and interruption of gas supply for large-scale users and other problems, to achieve the effect of easy disassembly operation, less construction preparation and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The best implementation mode of the present invention will be further described in detail below in conjunction with the accompanying drawings.

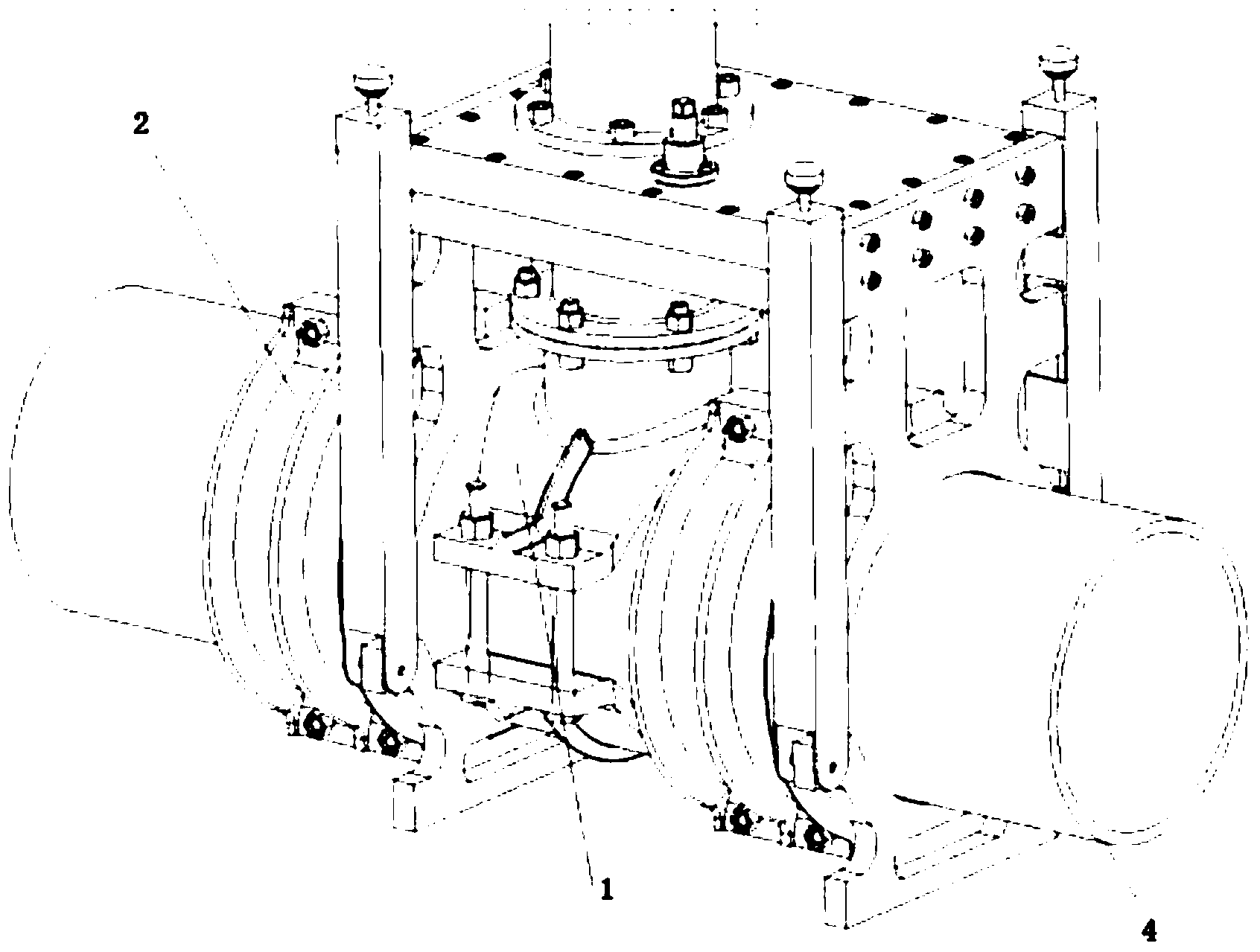

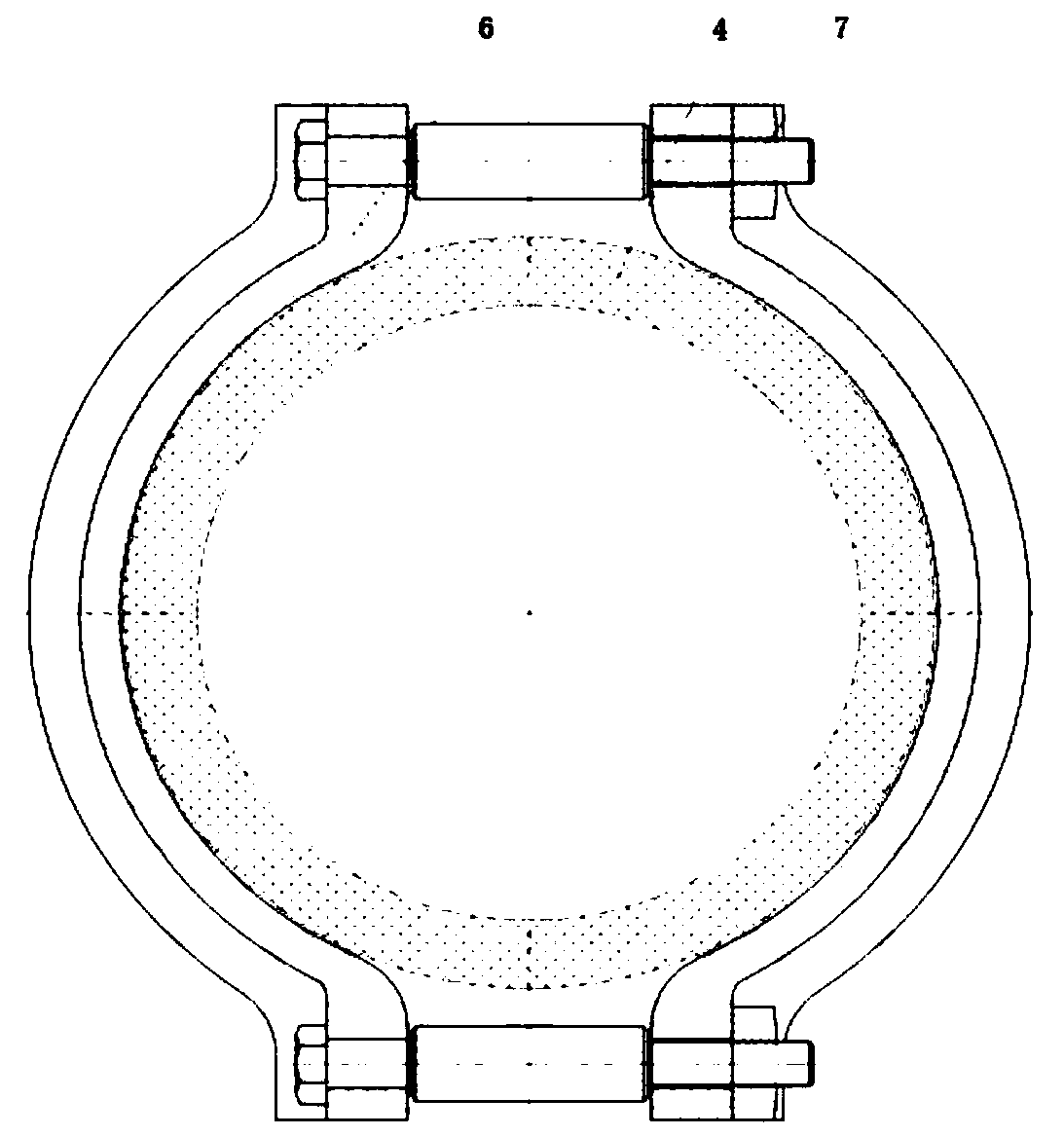

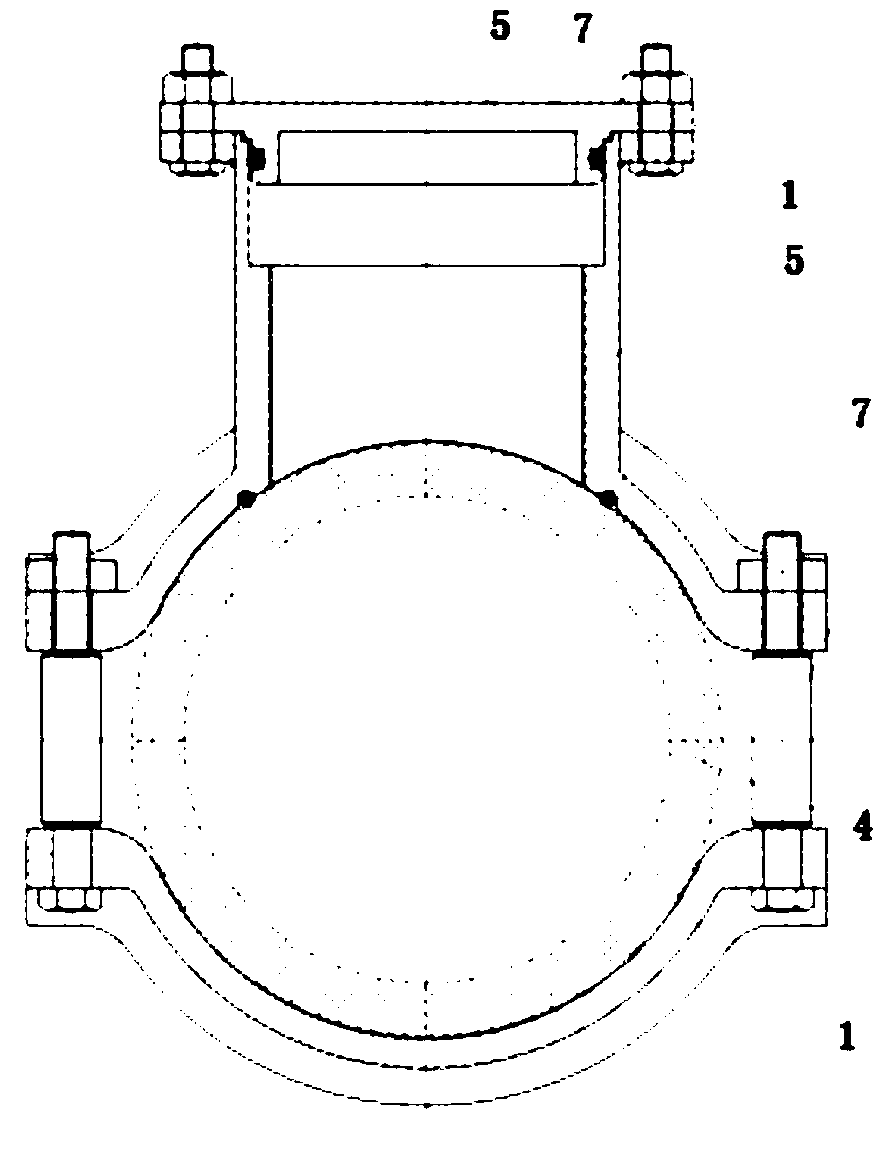

[0030] Such as Figure 1-7 As shown, a pipeline non-stop opening and sealing system includes a bracket 1, a pipeline rounder 2 and a pressurized pipeline cleaning device 3. The plugging operation pipeline 4 is connected; the pipeline recirculator 2 is made of aluminum alloy material as a whole, and is installed on the position where the hole required for the non-stop opening and sealing operation pipeline 4 is opened; the pressure and pressure pipeline cleaning device 3 is installed On the saddle-shaped bracket 1 of the steel material. The saddle-shaped support 1 of steel material is connected with the non-stop opening and sealing operation pipeline 4 through the sealing ring 5 . The pipe rounder 2 is composed of upper and lower slips 6 and bolts 7 . The pressurized pipeline cleaning device 3 includes a cleaning pipe 8 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com