Air supplying system and method of experiment table of small supercharged boiler

A pressurized boiler and air supply system technology, which is applied to steam boilers, combustion methods, steam boiler accessories, etc., can solve the problems of increasing the difficulty of space layout, increasing the complexity of the system, and small steam output, so as to achieve rapid response of electric regulation , save energy, reduce the effect of steam pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

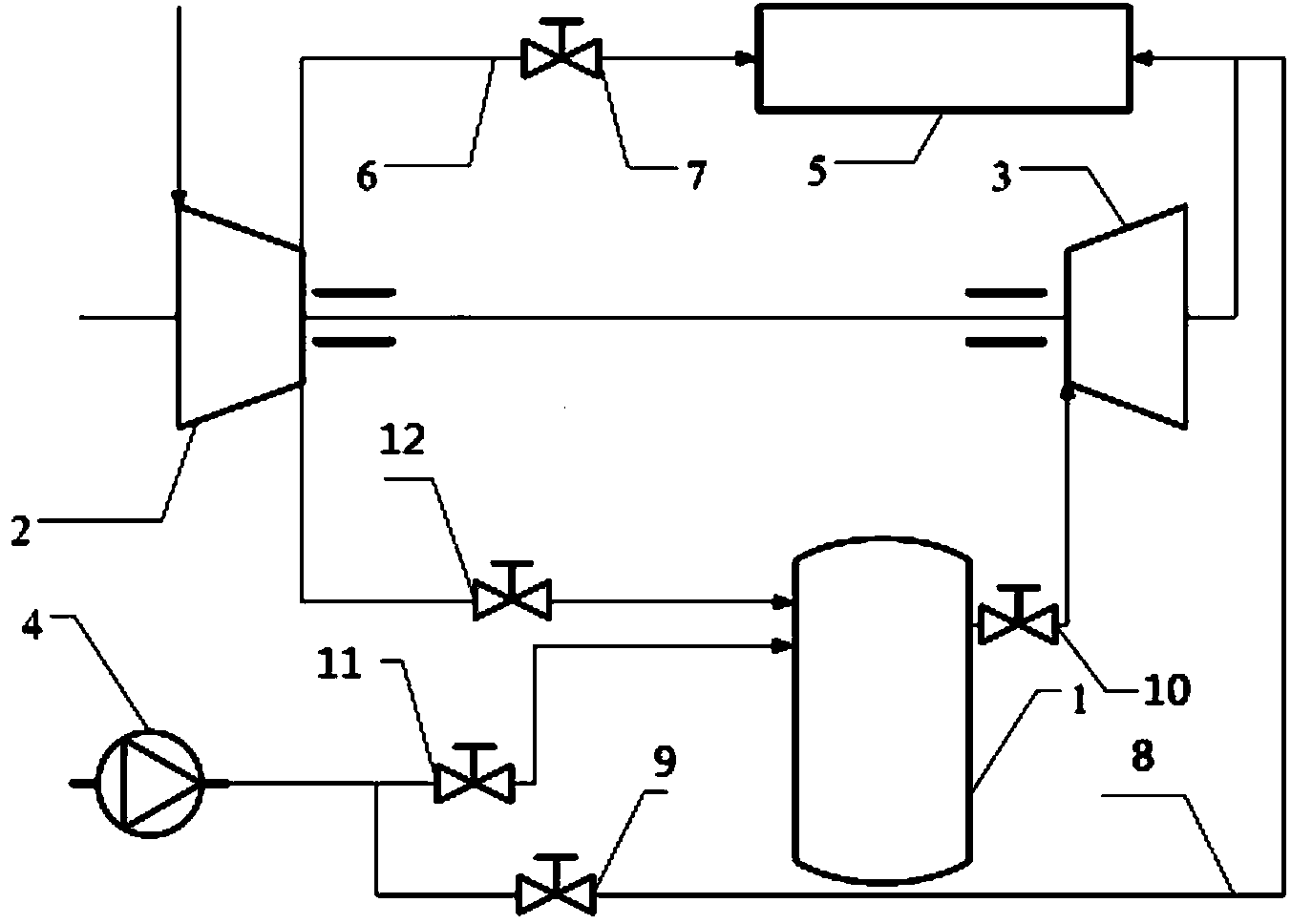

[0015] Such as figure 1 As shown, the air outlet of the supercharger 2 is connected to the air inlet of the supercharger boiler 1 through the pipeline, and the flue gas outlet of the supercharger boiler 1 is connected to the flue gas turbine 3 through the pipeline, and the flue gas turbine 3 is coaxially fixed with the supercharger 2. The air outlet of the Roots blower 4 is connected to the air inlet of the booster boiler 1 through a pipeline.

[0016] A regulating valve 10 is provided on the pipeline between the flue gas outlet of the booster boiler 1 and the flue gas turbine 3 to regulate the furnace pressure of the booster boiler. On the pipeline between the outlet of the Roots fan 4 and the air inlet of the booster boiler 1 Equipped with regulating valve.

[0017] A pressurized air bypass line 6 is connected between the supercharger 2 and the smoke exhaust line 5, and a regulating valve 7 is arranged on the pressurized air bypass line 6; The bypass pipeline 8 of the Root...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com