Electric heat-preservation stove for zinc powder production

A heat-preserving electric furnace, zinc powder technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of slow flow rate of zinc liquid, pipeline blockage, solidification, etc., to achieve uniform flow and prevent solidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

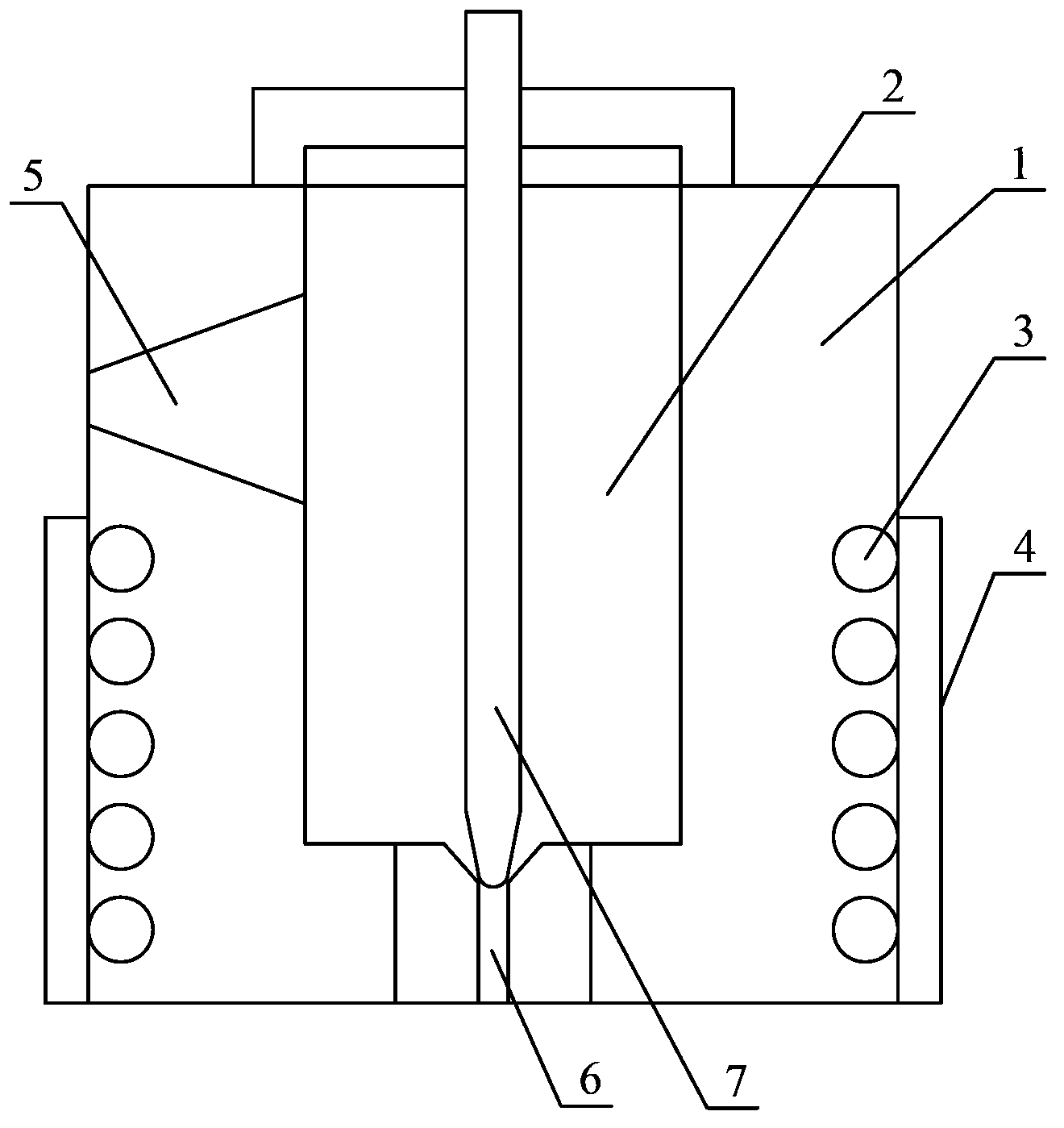

[0018] Such as figure 1 As shown, it includes a furnace body 1 provided with an inner cavity 2, and the periphery of the lower half of the furnace body is provided with a heating coil 3 wound on the furnace body 1 and an iron core 4 located outside the heating coil 3, The side wall of the upper half of the furnace body 1 is horizontally provided with an inflow hole 5, and the bottom of the furnace body 1 is vertically provided with an outflow hole 6, and a flow regulating device is arranged above the outflow hole 6, and the flow rate The adjusting device is arranged in the furnace body 1 and is threadedly connected with the furnace body 1 to adjust the rod 7, and the diameter of the inflow hole 6 gradually increases from the outside to the inside of the furnace body.

[0019] The lower end of the adjusting rod 7 is arc-shaped.

[0020] The heating coil 3 is embedded in the furnace body 1 .

[0021] The outflow hole 6 is funnel-shaped.

[0022] An embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com