Embedded measuring method for contact press of annular friction pair

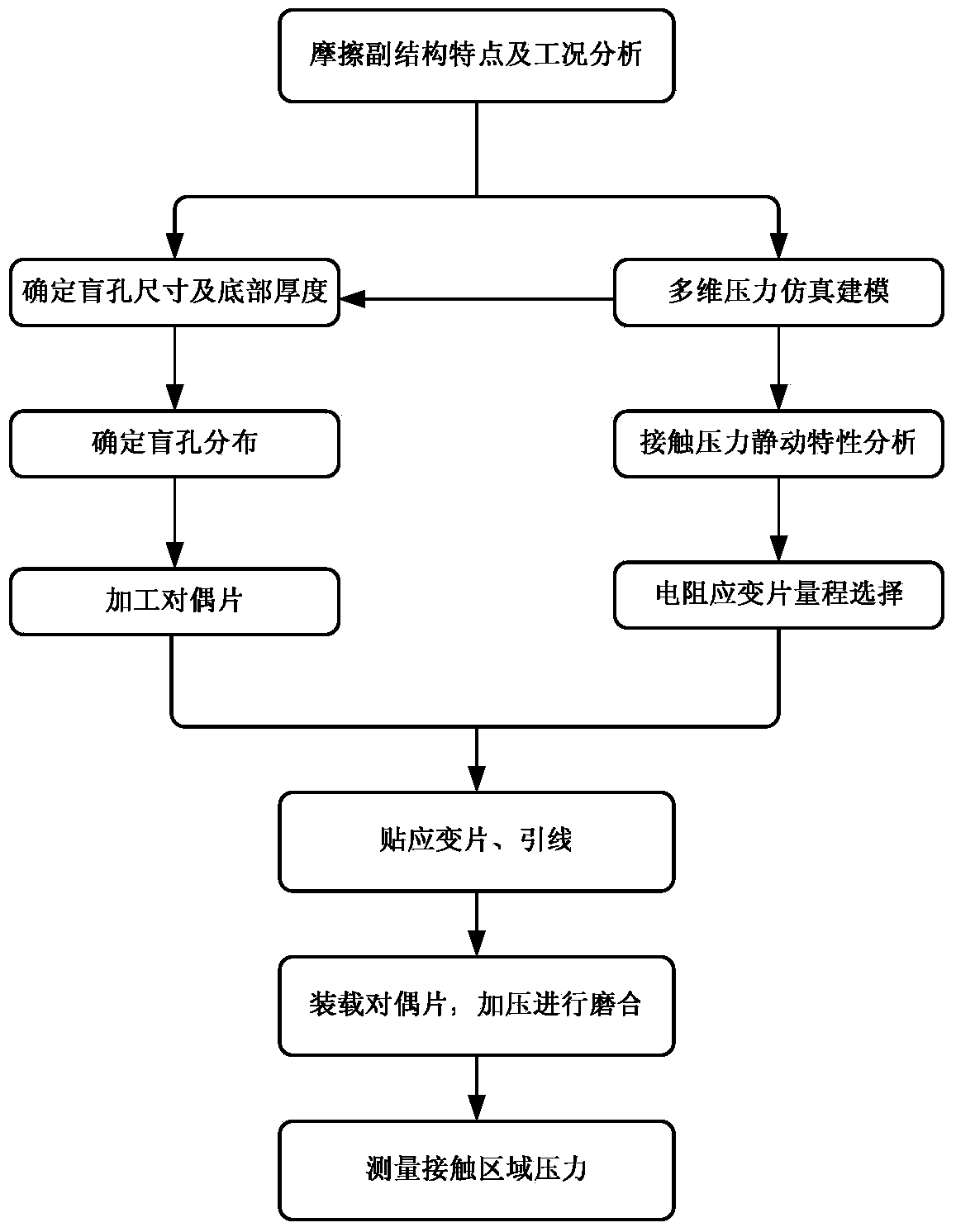

An embedded measurement and contact pressure technology, applied in the direction of measurement force, measurement device, instrument, etc., can solve the problems that the pressure distribution of the contact surface cannot be obtained realistically, and the boundary conditions of the friction pair pressure cannot be measured. The effect of low test cost and simple measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the method of the present invention will be described in detail below in conjunction with the accompanying drawings.

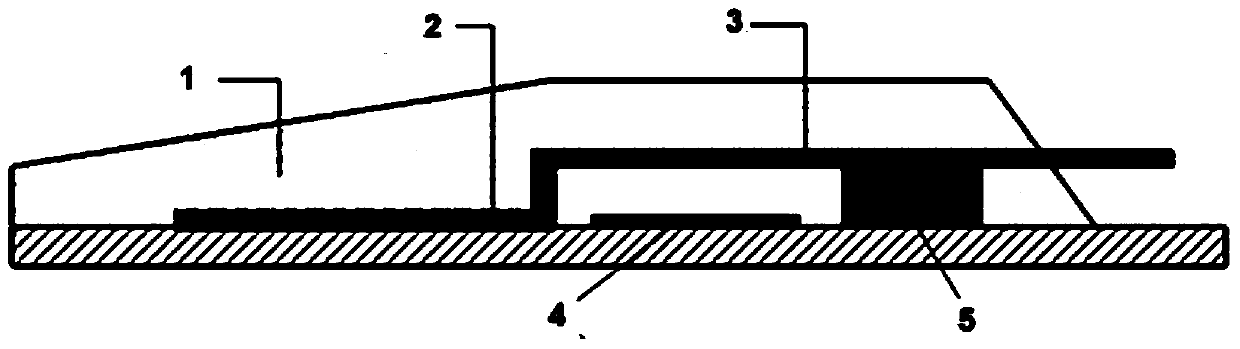

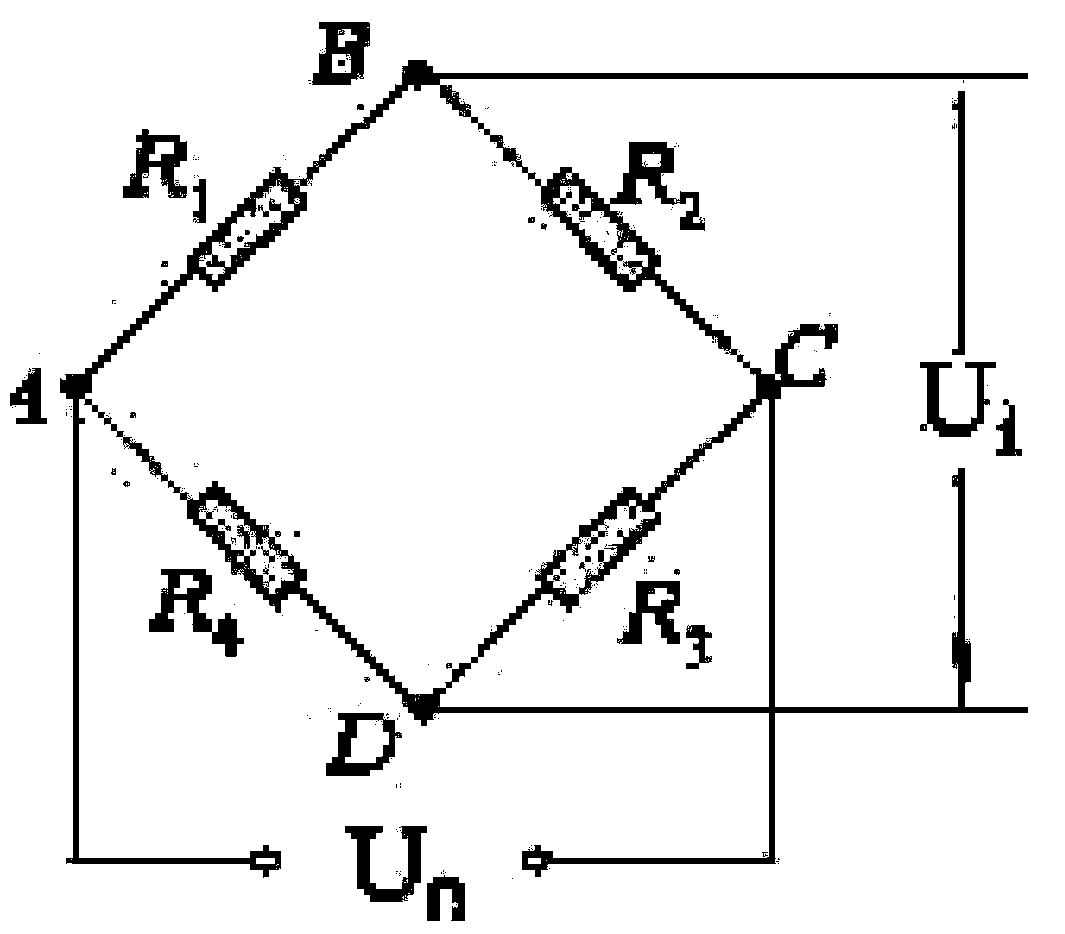

[0031] Both theoretical research and experimental process have found that the Cu-based powder metallurgy friction pair has the characteristics of uneven contact pressure distribution (especially in the radial direction) during the bonding process and bonding state. This characteristic is due to the characteristics of the pressurized structure and the characteristics of the contact surface jointly decided. The invention adopts the embedded blind hole measurement method to realize the measurement of the static and dynamic contact pressure of the friction pair.

[0032] In order to test the contact pressure of the friction pair, a number of blind holes are processed on the non-contact surface of the dual steel sheet. The size and distribution characteristics of the blind holes need to be determined according to the size of the frictio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com