Monitoring index switching based multi-operating-mode process monitoring method and system

A technology for monitoring indicators and process monitoring, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as inaccuracy, inability to monitor equipment working conditions, and lack of working condition identification to achieve high applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

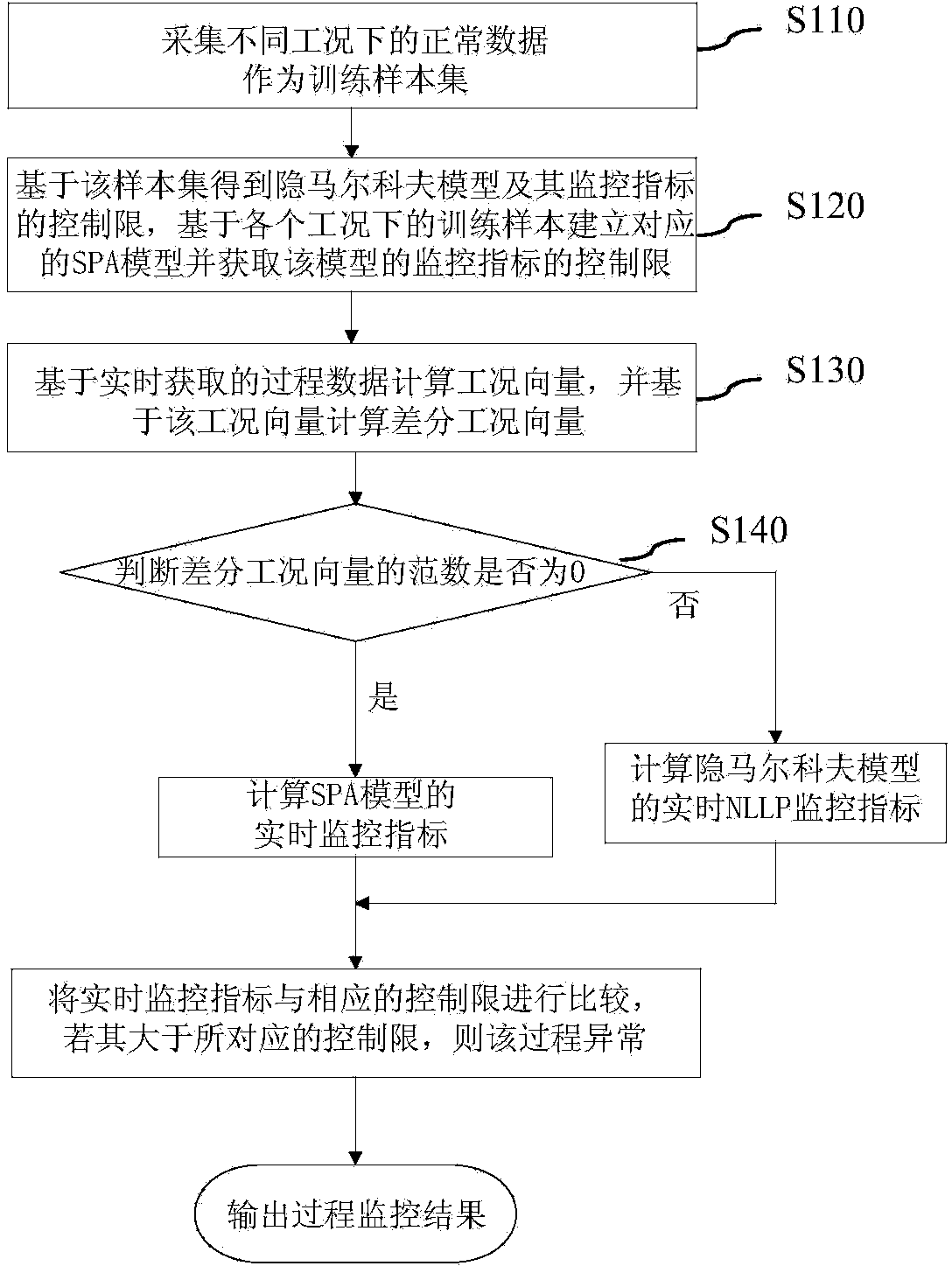

[0040] figure 1 It is a flowchart of a multi-working-condition process monitoring method based on monitoring index switching according to an embodiment of the present invention. Combine below figure 1 This method will be described in detail.

[0041] Step S110, collecting normal data under different working conditions (that is, the working status of the power equipment under certain conditions) as a training sample set.

[0042] Specifically, the normal data under different working conditions are obtained from the chemical process database as the training sample set: in, (i=1,...M) is the data sample of the i-th working condition, Represents a real number matrix with N rows and m columns, N i Indicates the number of samples of the i-th working condition, N indicates the total number of samples, and m indicates the number of sensors.

[0043] Step S120, obtain the hidden Markov model based on the training sample set, and obtain the control limit corresponding to the mo...

example 1

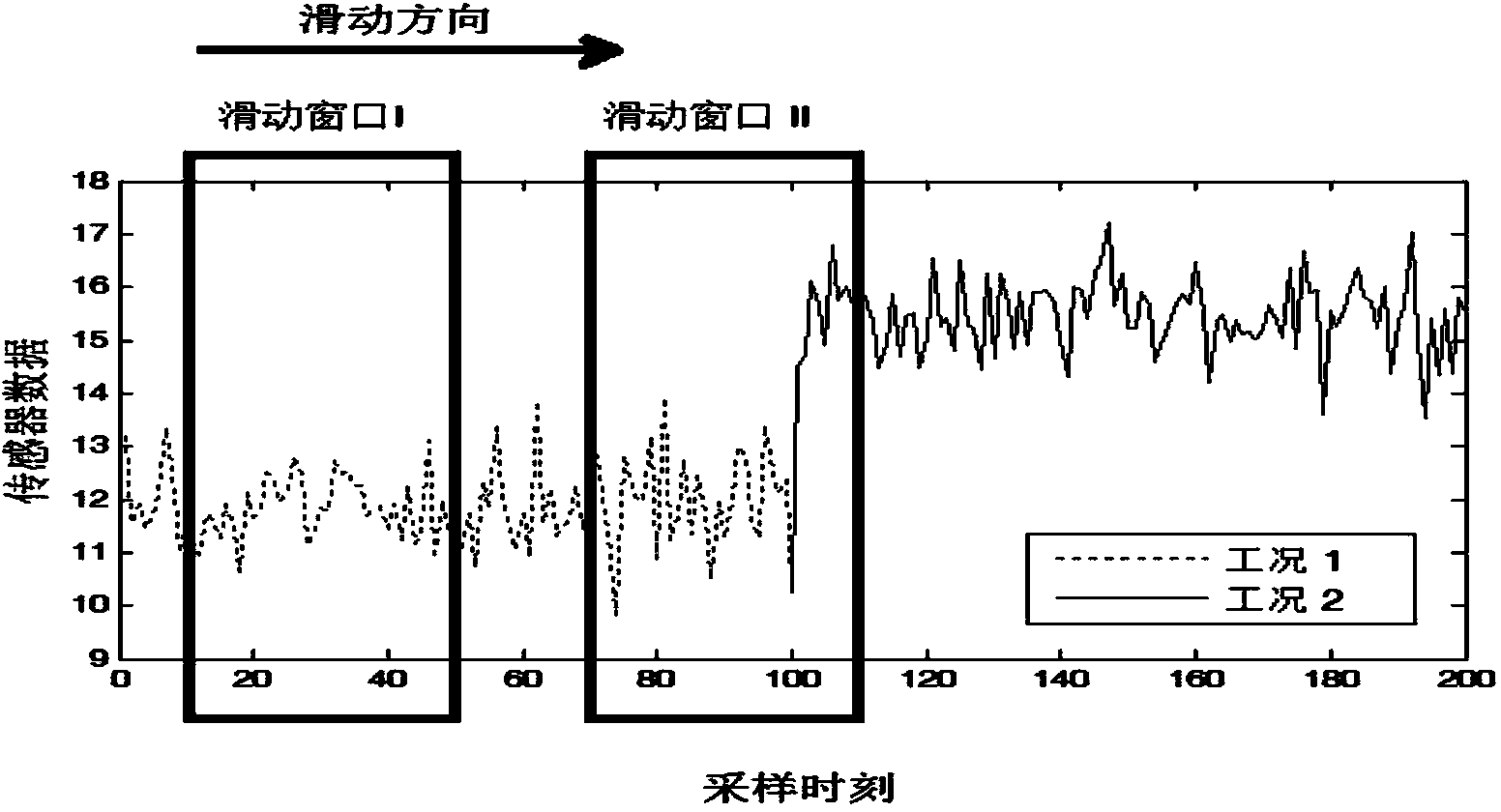

[0067] Example 1: Numerical Simulation

[0068] Generate data using the following linear system:

[0069] x 1 x 2 x 3 = 0.3723 0.6815 0.4890 0.2954 0.9842 0.1793 s 1 s 2 + ...

example 2

[0083] Example 2: Continuous Stirred Heating Tank (CSTH)

[0084] Figure 10 Shown is a schematic structural diagram of a continuous stirring heating tank. In the figure, TC is a temperature controller, FT is a flow transmitter, FC is a flow controller, TT is a temperature transmitter, LC is a liquid level controller, and LT is a liquid level transmitter.

[0085] In a continuously stirred heated tank, hot and cold water are thoroughly mixed in the tank and heated by steam. There are multiple control loops in the system to ensure that the liquid level, flow and temperature work at the set operating point. Table 3 reflects the parameters corresponding to the two standard working conditions of the continuous stirring heating tank, where the unit of each physical measurement (electrical signal) is milliampere (mA).

[0086] Table 3. The parameters corresponding to the two standard working conditions of the continuous stirring heating tank

[0087]

[0088] Table 4 is a des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com