A kind of high coercive force NdFeB permanent magnet material and preparation method thereof

A permanent magnet material, high coercivity technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problems of inability to guarantee material uniformity and low coercivity, and achieve high coercivity and raw material cost. Low, quality-assured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

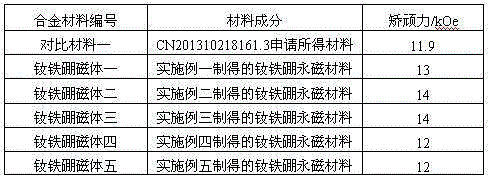

Embodiment 1

[0027] The preparation method of the high coercive force NdFeB permanent magnet material of the present invention, the specific steps are as follows:

[0028] (1) La3%, Ce2%, Nd22%; Co0.5%, Cr0.3%; Pb0.5%, B0.5%, Si0.5%, Sc0.3%, Sb0 are respectively taken according to the following weight percentages .5%, and the rest is Fe for batching; the purity of La, Ce, Nd, Co, Cr, Pb, Sb, B, Si, Sc and Fe are all greater than 99.9%;

[0029] (2) Put the raw materials into a vacuum induction furnace for melting, the melting temperature is 1660°C, and after standing for 2 minutes, the master alloy liquid is obtained;

[0030] (3) Cast the master alloy liquid onto the roller below the taphole of the induction furnace. The master alloy liquid encounters the rotating roller and is dragged by the roller rim to form a casting belt; the rotational speed of the roller rim is 12m / s; the thickness of the casting belt is about 200μm, and the width is about 10mm;

[0031] (4) Cool the cast strip n...

Embodiment 2

[0036] The preparation method of the high coercive force NdFeB permanent magnet material of the present invention, the specific steps are as follows:

[0037] (1) La8%, Ce4%, Nd25%, Co1%, Cr0.6%; Pb1%, B1%, Si0.7%, Sc0.6%, Sb0.9% are taken according to the following weight percentages, and the rest are Fe is used for batching; the purity of La, Ce, Nd, Co, Cr, Pb, Sb, B, Si, Sc and Fe are all greater than 99.9%;

[0038] (2) Put the raw materials into a vacuum induction furnace for melting, the melting temperature is 1700°C, and after standing for 3 minutes, the master alloy liquid is obtained;

[0039] (3) Cast the master alloy liquid onto the roller below the taphole of the induction furnace. The master alloy liquid encounters the rotating roller and is dragged by the roller rim to form a casting belt; the rotational speed of the roller rim is 14m / s; the thickness of the casting belt is about 400μm, and the width is about 20mm;

[0040] (4) Cool the cast strip naturally fo...

Embodiment 3

[0045] The preparation method of the high coercive force NdFeB permanent magnet material of the present invention, the specific steps are as follows:

[0046] (1) Take La5%, Ce3%, Nd23%, Co0.8%, Cr0.5%, Pb0.7%, B0.8%, Si0.6%, Sc0.4%, Sb0 according to the following weight percentages respectively .7%, and the rest is Fe for batching; the purity of La, Ce, Nd, Co, Cr, Pb, Sb, B, Si, Sc and Fe are all greater than 99.9%;

[0047] (2) Melting the raw materials in a vacuum induction furnace at a melting temperature of 1780°C and standing for 4 minutes to obtain a master alloy liquid;

[0048] (3) The master alloy liquid is cast on the roller below the taphole of the induction furnace. The master alloy liquid encounters the rotating roller and is dragged by the roller rim to form a casting belt; the rotational speed of the roller rim is 16m / s; the thickness of the casting belt is about 600μm, and the width is about 30mm.

[0049] (4) Cool the cast strip naturally for 10 minutes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com