High-isolation voltage electric-light-electric isolation structure

A high isolation, electrical isolation technology, applied in the field of electrical isolation, can solve the problems of increased isolation voltage, weak electrical signal, unable to meet demand, etc., to achieve the effect of increasing isolation voltage, large isolation voltage, and increasing spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

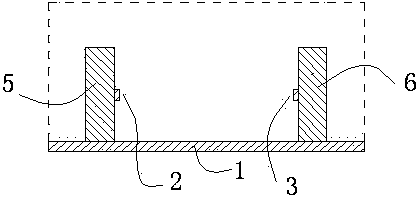

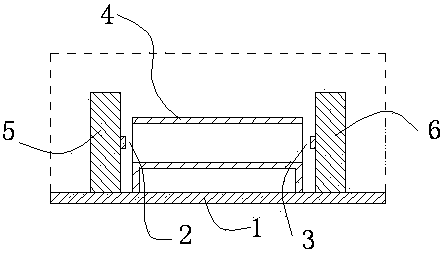

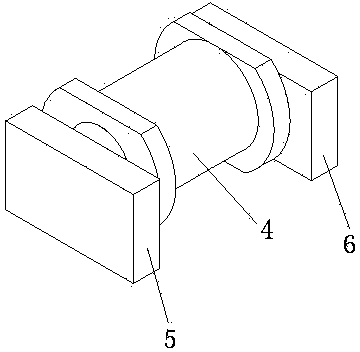

[0016] In the prior art, the distance between the light source chip 2 and the light detection chip 3 is generally set at about 1.8 mm. At this time, the isolation voltage of the electrical-optical-electrical isolation structure is about 10,000 volts. If the light source chip 2 and the optical detection chip are further increased 3, the electrical signal converted by the light detection chip 3 weakens rapidly. When the light source chip 2 and the light detection chip 3 increase to more than 2.2 mm, the electrical signal converted by the light detection chip 3 will attenuate to a level that cannot meet the demand.

[0017] By adopting the solution of the present invention, the distance between the light source chip 2 and the light detection chip 3 can be extended to more than 6 mm, and the isolation voltage can reach more than 30,000 volts, and has the potential for further improvement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com