Storage battery with light side negative plates as well as lamination method thereof

A side negative plate, battery technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve the problems of affecting battery life, waste of negative plate material, and fast utilization rate of positive plate, etc., to save Material consumption, guaranteed service life, and the effect of reducing lead consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

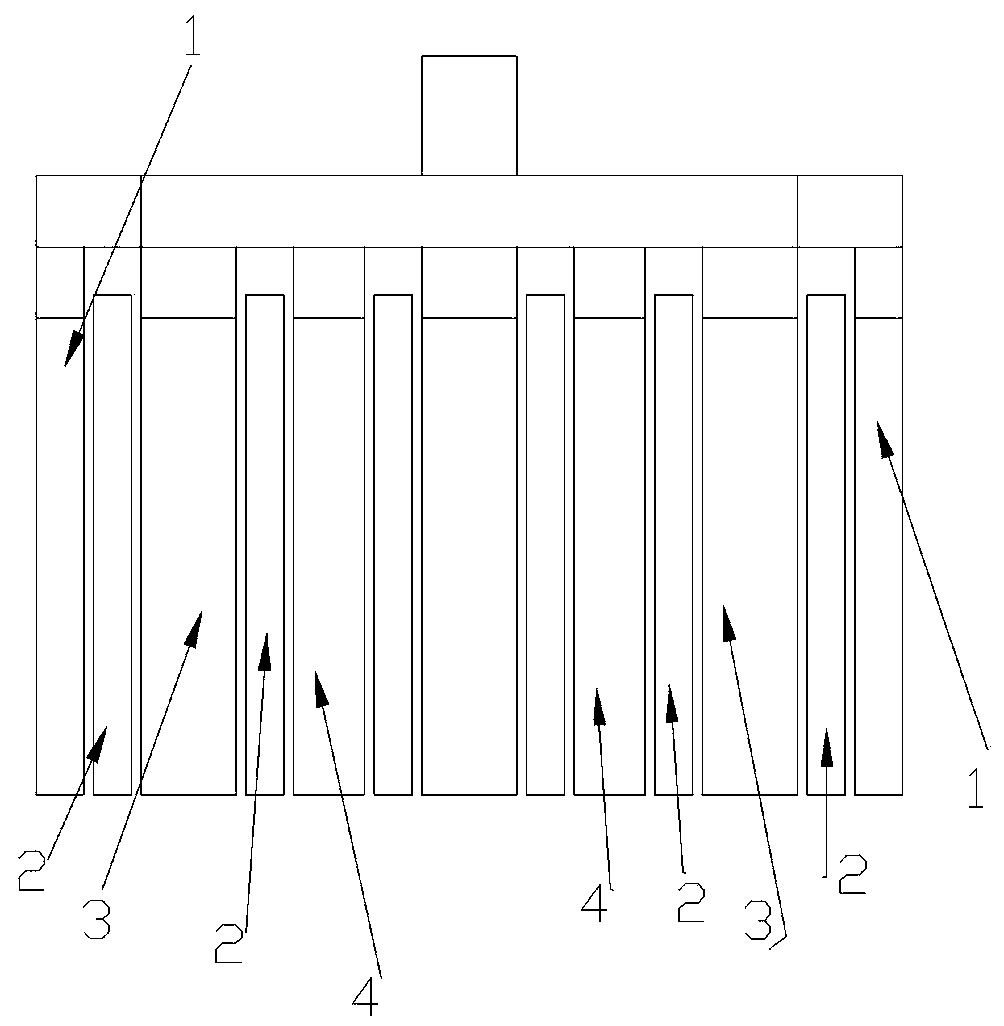

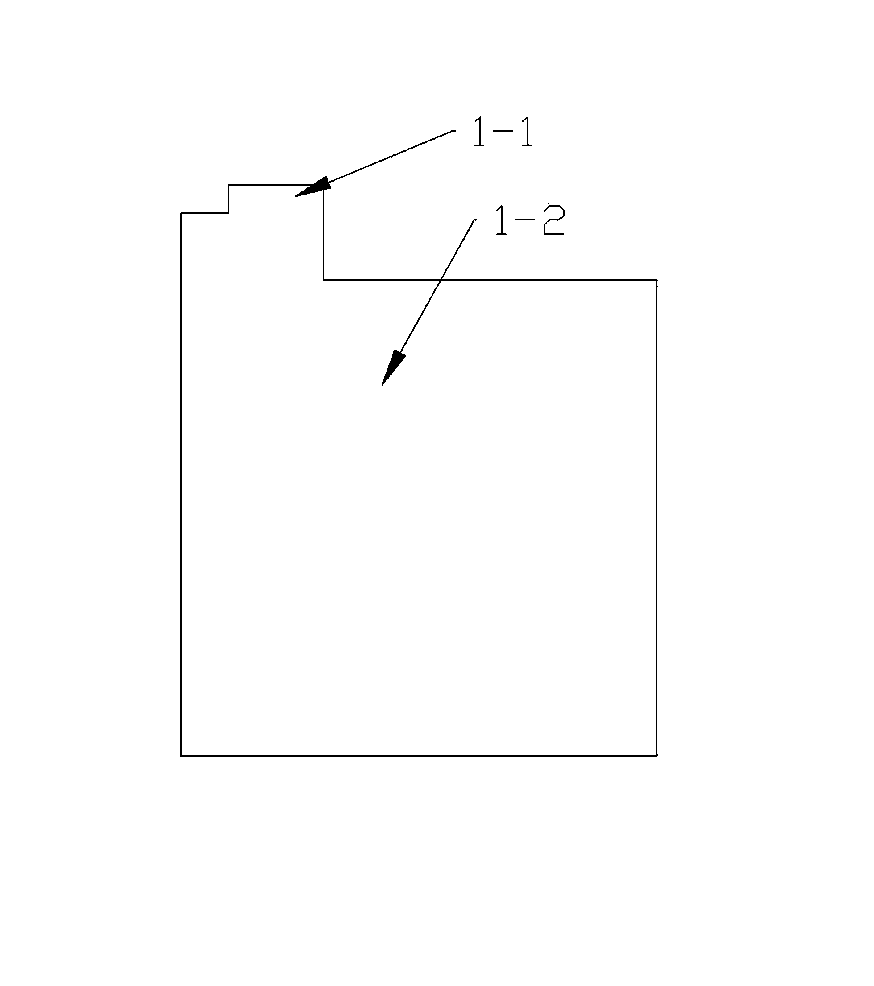

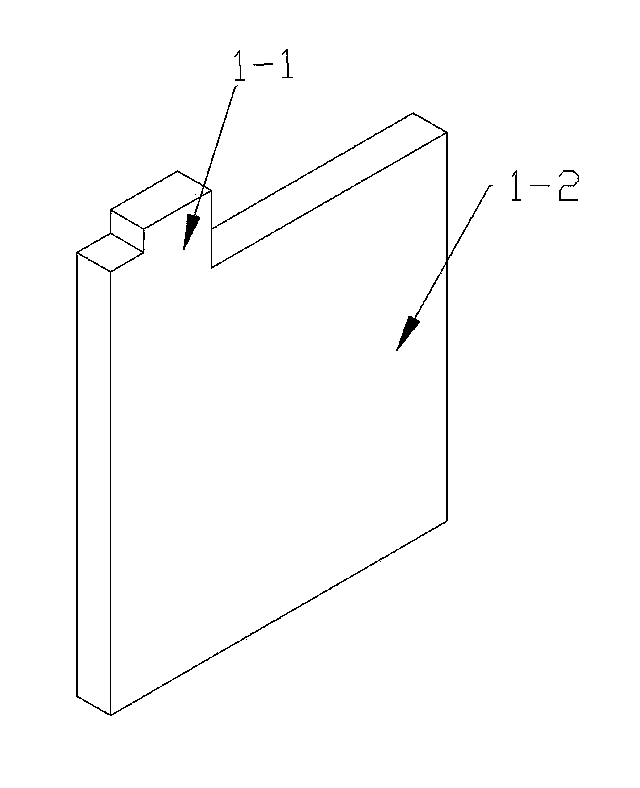

[0026] see Figure 1~4 , a light-edge negative plate storage battery, comprising a housing, and a pole group arranged in the housing, the pole group comprising a negative plate, a paper separator 2, and a positive plate 3, and a positive confluence is provided on the upper part of the positive plate 3 The positive bus bar is provided with a positive terminal, the negative bus bar is provided with a negative bus bar, and the negative bus bar is provided with a negative terminal. The negative plate and the positive plate 3 are arranged alternately in sequence. A paper separator 2 is arranged between the board and the positive board 3, the negative board includes a board surface 1-1 and a plate lug 1-2 arranged on the upper side of the board surface 1-1, and the negative board includes a The two side negative plates 1 at the edge positions and the middle negative plate 4 arranged in the housing, the thickness of the side negative plates 1 is smaller than the thickness of the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com