Performance improvement method and structure of direct alcohol fuel cell

A fuel cell, direct technology, applied in the direction of fuel cells, fuel cell additives, circuits, etc., can solve problems such as the inability to reduce the cost of DMFC, achieve good results, improve the starting voltage, and solve technical bottlenecks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

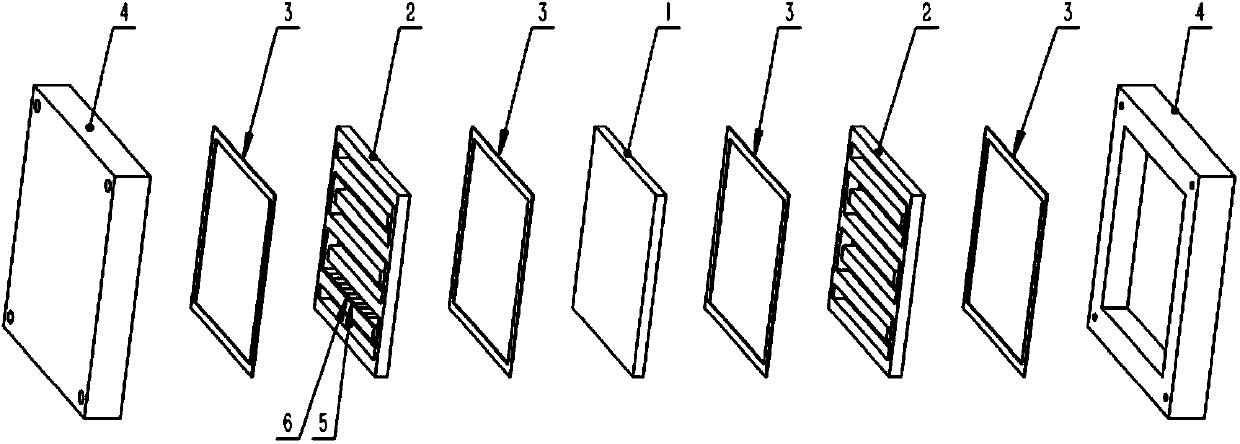

[0023] refer to figure 1 The structure decomposition diagram of the direct alcohol fuel cell is shown, two fuel supply channels 2 are sandwiched between the MEA membrane 1, sealed by the sealing ring 3, packaged by the packaging shell 4, and the piezoelectric ceramic 5 is arranged on the separator of the fuel supply channel On and out of the electrode 6 to provide power.

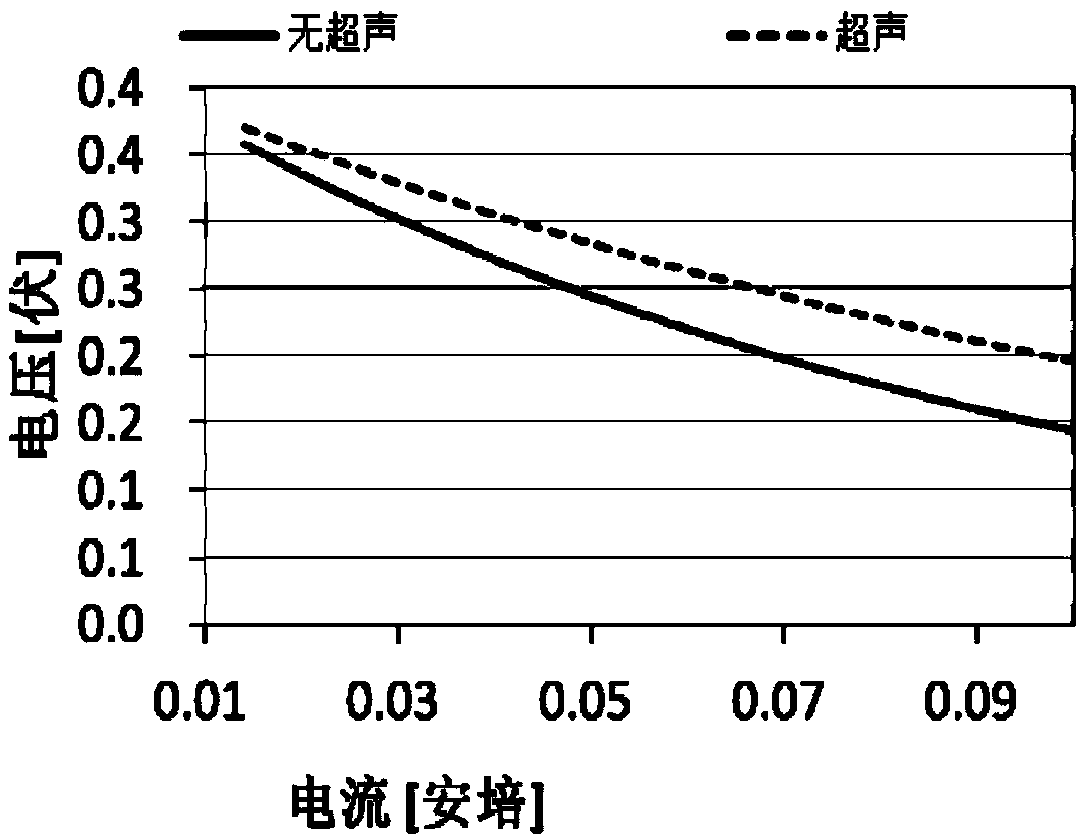

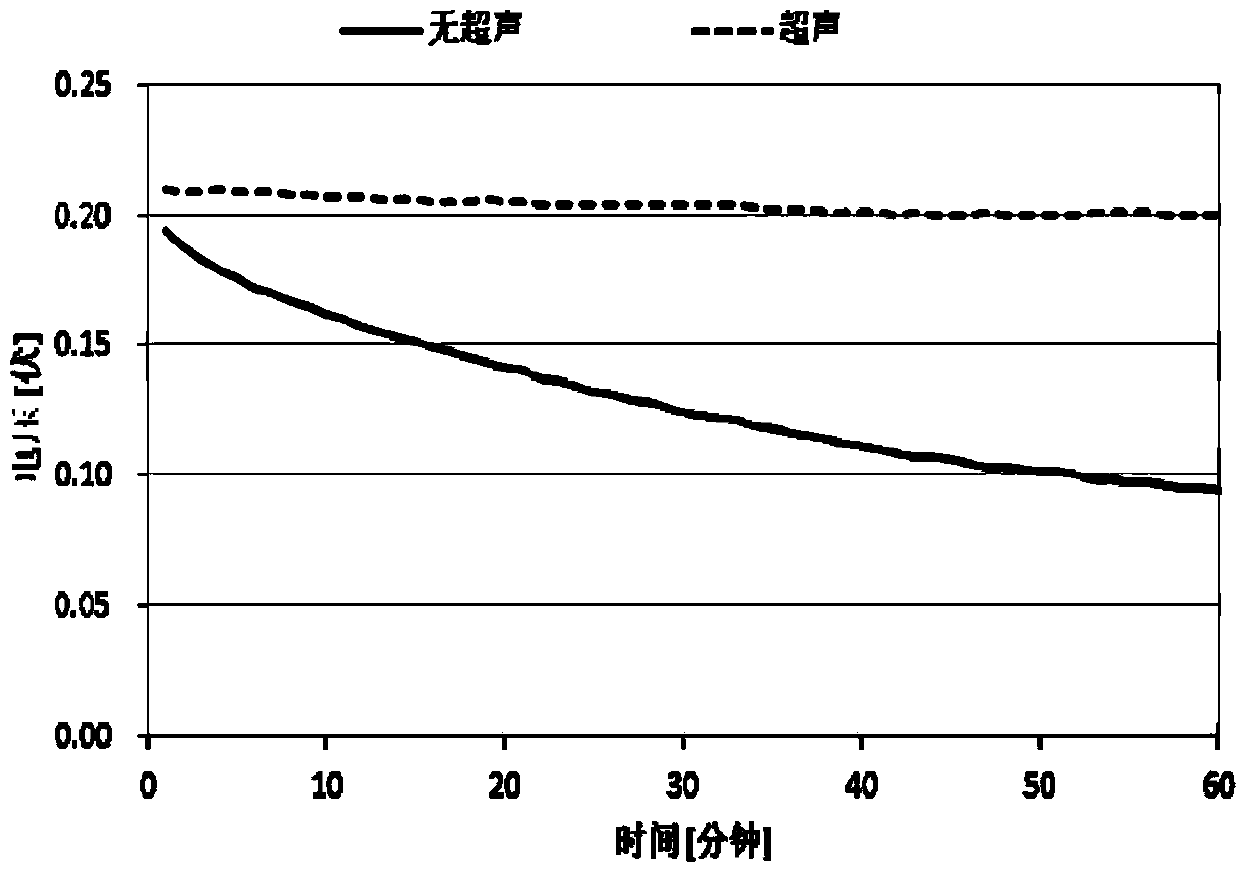

[0024] The traditional direct alcohol fuel cell with the ultrasonic transducer set according to the above scheme, electrifying the ultrasonic transducer and generating ultrasonic vibration to the anode fuel supply channel, the transient performance and steady-state discharge performance of the battery are significantly improved.

[0025] The experience in the specific implementation process shows that the ultrasonic transducer is installed on the partition, sealing device or packaging shell of the anode fuel supply channel by means of adhesion, inlay or embedding, as long as the anode fuel supply channel can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com