internal combustion engine

A technology of internal combustion engine and camshaft, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems such as the deterioration of the working cylinder inflation principle, and achieve the effect of improving operating characteristics and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

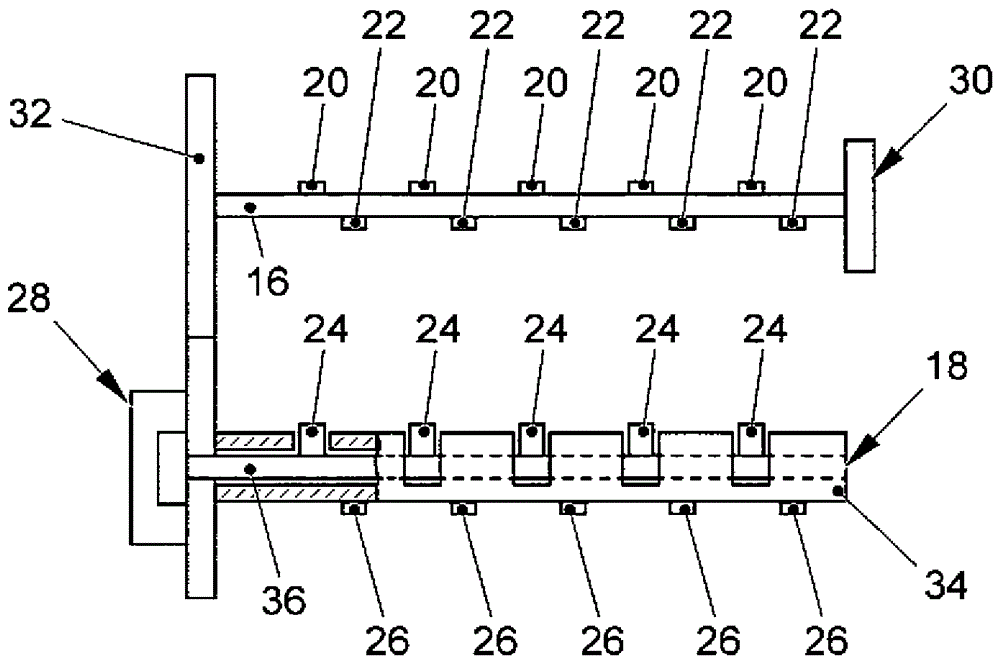

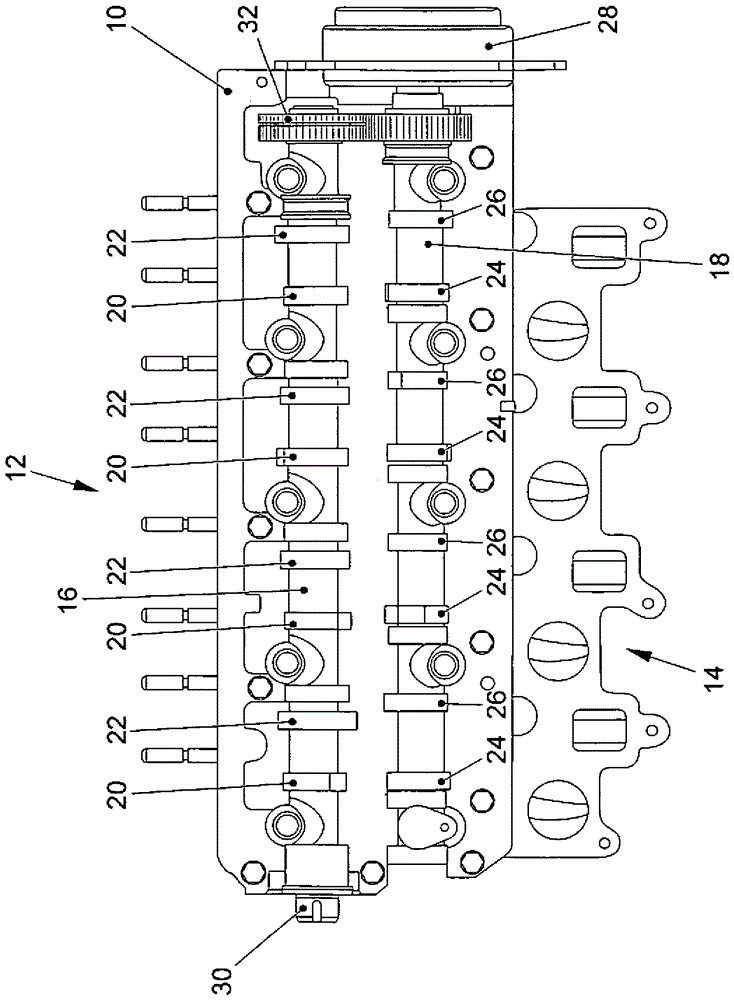

[0027] in figure 1 The embodiment of the internal combustion engine according to the present invention shown in includes a cylinder head 10 into which a working cylinder not shown in detail is integrated. In the working cylinder, there are pistons (not shown) running back and forth between top dead center (OT) and Movement between bottom dead center (UT). The cylinder head 10 includes an exhaust side 12 (where exhaust gas is directed from the working cylinder) and an intake side 14 (where fresh gas is delivered to the working cylinder).

[0028] Each working cylinder is associated with two intake valves (not shown) and two exhaust valves (not shown), in which a fixed camshaft 16 and a variable camshaft 18 are provided. The fixed camshaft 16 carries an intake cam 20 respectively operating intake valves and an exhaust cam 22 respectively operating exhaust valves. Likewise, the variable camshaft 18 carries an intake cam 24 which respectively manipulates the intake valves and an exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com