Magnesium alloy extrusion die capable of automatically controlling temperature and lubricating and using method thereof

An extrusion die and magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems of product surface oxidation, danger, uneven heating, etc., and achieve the effects of uniform flow rate, easy operation, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

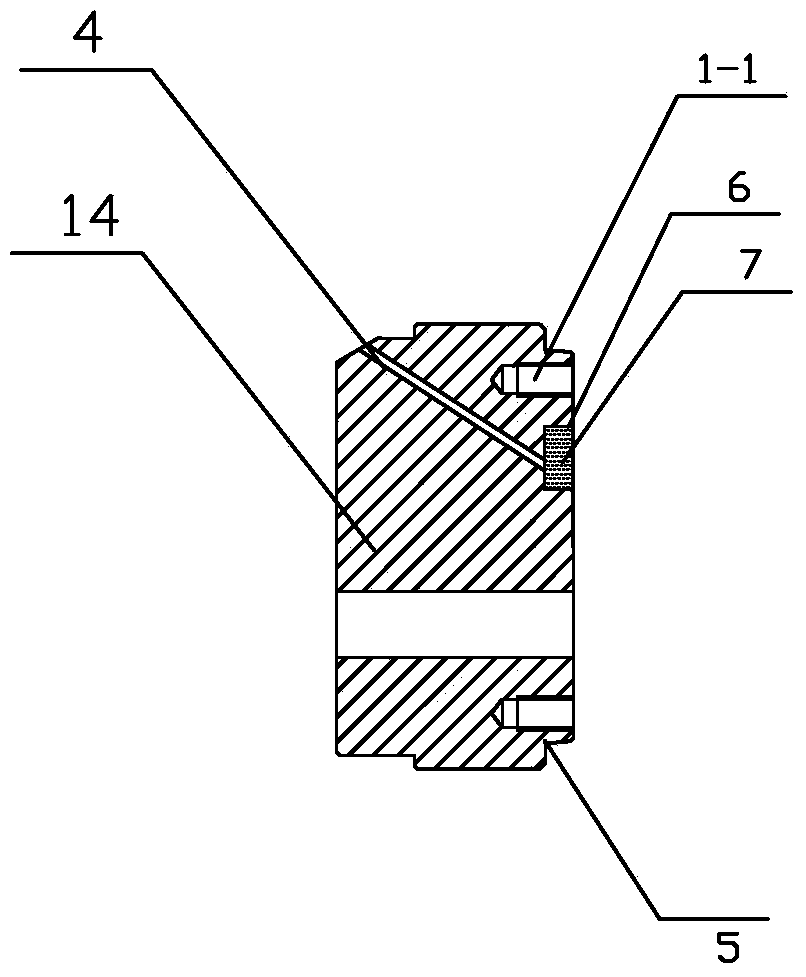

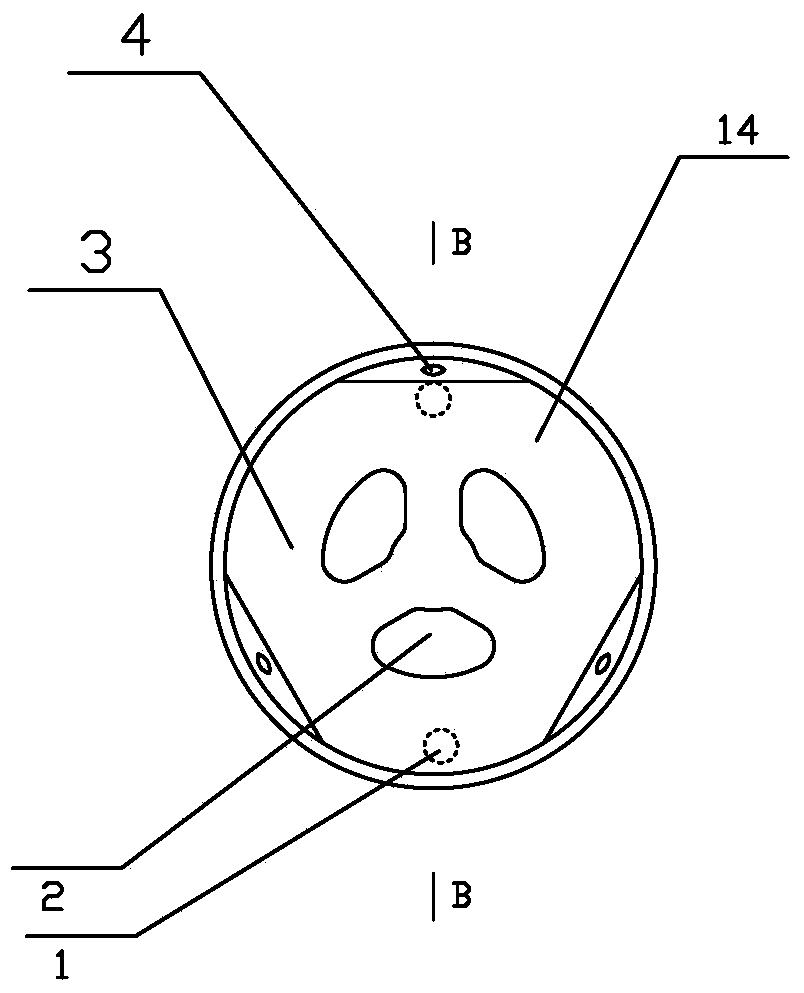

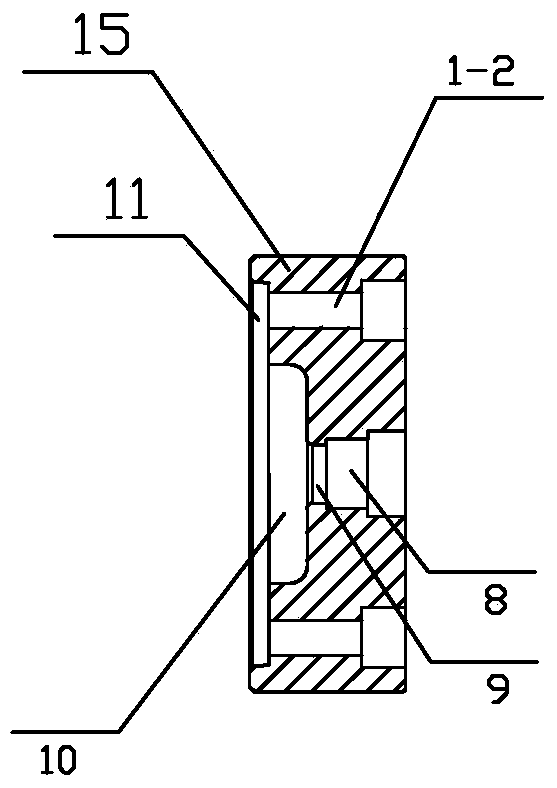

[0027] The magnesium alloy extrusion die with automatic temperature control and lubrication of the present invention comprises an upper die and a lower die, the upper die includes an upper die body 14 and the lower die includes a lower die body 15, a die sleeve is arranged outside the die, and a spiral is arranged on the inner wall of the die sleeve Groove 13, the coil 12 is placed in the spiral groove 13; Bridge position 3 is provided on the upper mold body 14, and the middle of the bridge position 3 is provided with a feed port 2, and the outer rear end of the upper mold body 14 is provided with a tail stop 5, and the upper mold body 14 is provided with a tail stop 5. A through hole 4 is arranged on the wall of the mold body 14, and the front end of the through hole 4 is connected with a digital greaser. The end of the through hole 4 is provided with a concave platform 6, and a loose layer 7 is arranged inside the concave platform 6. The upper mold and the lower mold buckle an...

Embodiment 2

[0039] The mold structure and method of use of this embodiment are the same as those of Embodiment 1, the difference is that:

[0040] The grease is butter with a mass fraction of 7% molybdenum disulfide.

[0041] The extrusion barrel temperature is 450°C, the mold temperature is controlled at 430°C, the charge temperature is controlled at 480°C, and the extrusion ratio is 30.

Embodiment 3

[0043] The mold structure and method of use of this embodiment are the same as those of Embodiment 1, the difference is that:

[0044] The grease is butter with a mass fraction of 7% molybdenum disulfide.

[0045] The extrusion barrel temperature is 400°C, the mold temperature is controlled at 380°C, the charge temperature is controlled at 380°C, and the extrusion ratio is 100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com