Welding device and welding technology applying multifunctional fillet welding trolley to horizontal position welding

A fillet welding trolley and welding device technology, which is applied to auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of unsightly welding seam formation, high operator requirements, and complicated operation, and achieves simple and convenient horizontal welding operation. Scope of application, the effect of high qualified rate of flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

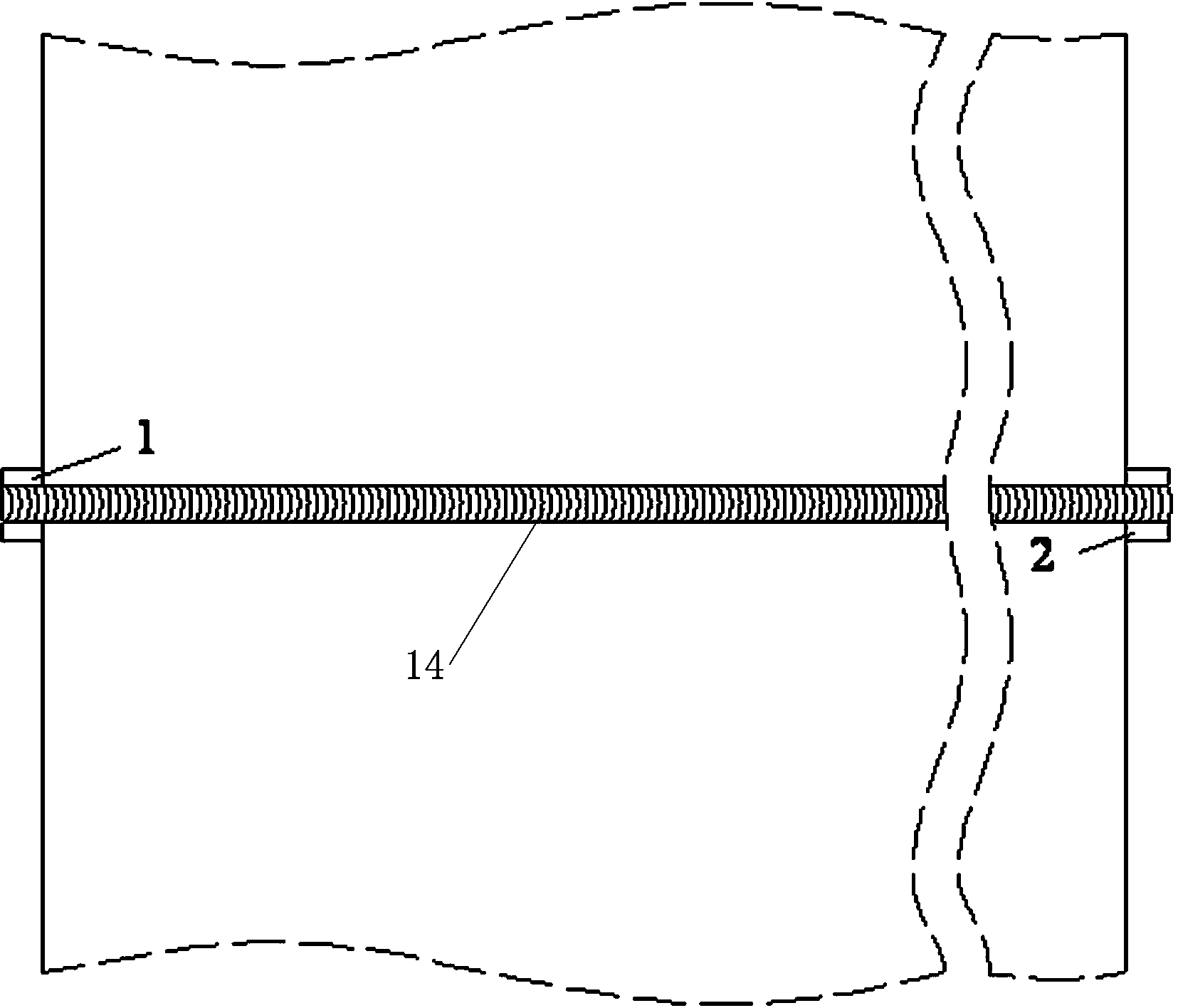

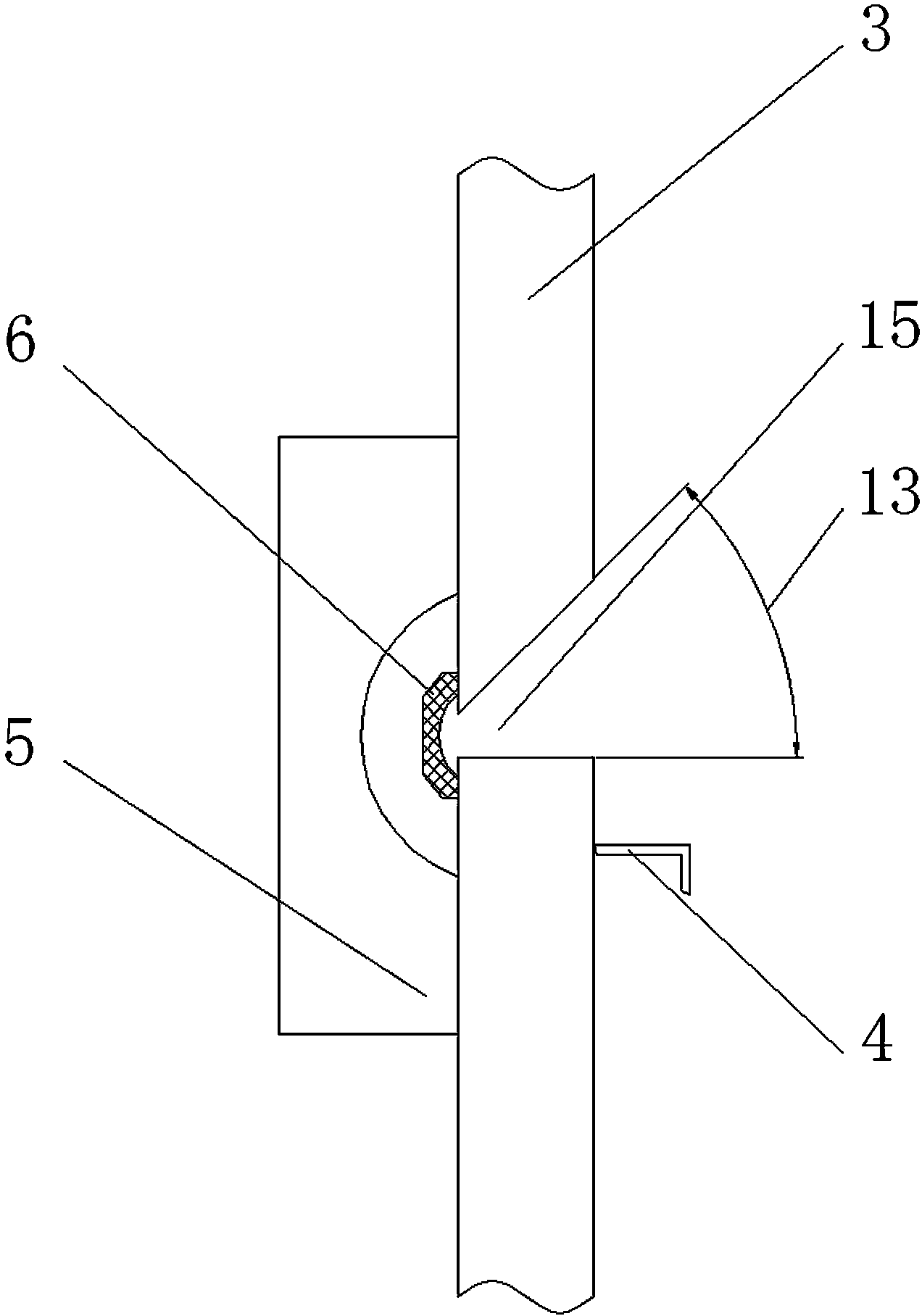

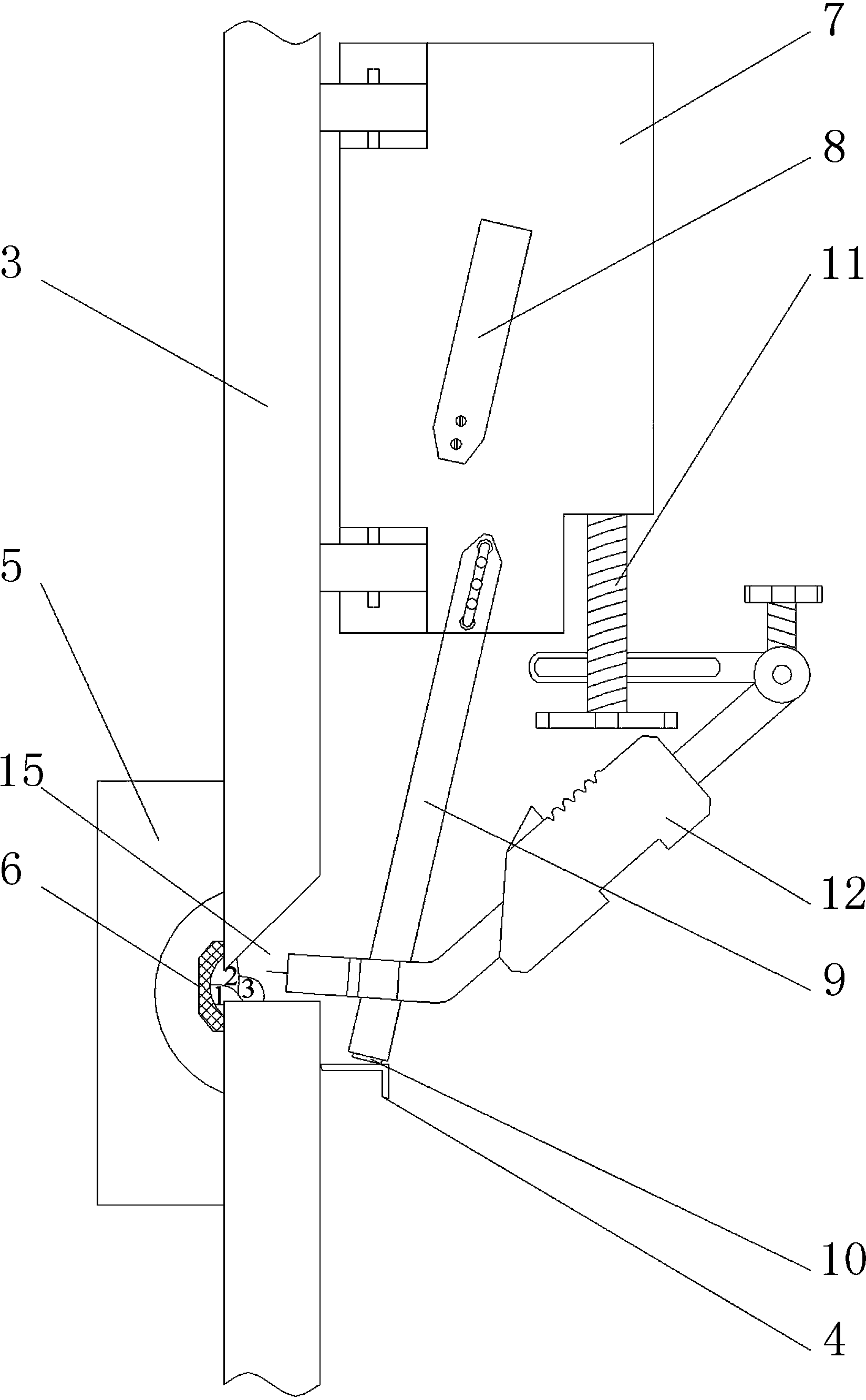

[0024] Such as Figure 1-4 As shown, a welding device using a multifunctional fillet welding trolley for horizontal welding in the present invention includes a fillet welding trolley 7, and the fillet welding trolley 7 is arranged on one side of the weldment 3, and between the weldments 3 A welding bead 14 is provided, and the first and last ends of the weldment 3 are equipped with an arc striking plate 1 and an arc extinguishing plate 2 respectively. A ceramic liner 6 is pasted on the weld bead on the back of the piece 3, and the back of the weldment 3 is also provided with a horse plate 5. 8, guide wheel arm 9 and welding torch 12, one end of the guide wheel arm 9 is set on the fillet welding trolley 7, the other end reaches the angle steel baffle plate 4 through the guide wheel 10, and one end of the welding torch 12 is connected to the fillet welding trolley 7 , the other end is aligned with the position of the welding bead 14, and the gap between the fillet welding troll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com