Electromagnetism and hydraulic pressure compound brake with self power generation function and working method

A compound braking and electromagnetic braking technology, applied in electric braking systems, electric vehicles, electric energy management, etc., to reduce the dependence on the battery, solve the problem of insufficient capacity, and ensure the effect of coordinated work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

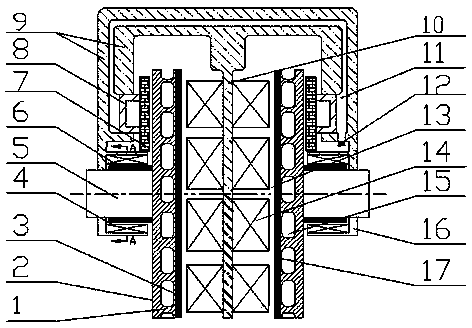

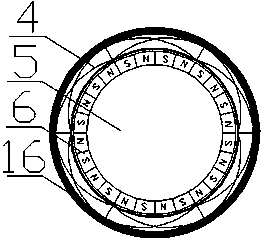

[0019] see figure 1 , the present invention includes a brake bracket 9, and the installation position and method of the brake bracket 9 and the brake caliper bracket in the traditional hydraulic braking system are the same. Two left and right wheel cylinders are installed on the brake bracket 9, a hydraulic oil circuit 11 is opened inside the brake bracket 9, and an oil inlet 12 is opened on the brake bracket 9, and the hydraulic oil circuit 11 is connected to the wheel cylinders of the left and right wheel cylinders Piston 8, there are two composite brake discs 1 between the left and right wheel cylinder pistons 8, between the two composite brake discs 1 is an electromagnetic coil bracket 10 and an electromagnetic coil 14, and the electromagnetic coil 14 is fixedly installed on the electromagnetic coil bracket 10, while the electromagnetic coil bracket 10 is fixedly connected to the brake bracket 9. There are 16-24 electromagnetic coils 14. In order to ensure the compactness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com