Bituminous pavement digging-milling-repairing integrated system device

A system device and asphalt pavement technology, applied in the fields of pavement machinery technology, highway construction equipment technology, and asphalt pavement maintenance and repair equipment, can solve the problems of poor mobility, inability to meet the requirements of grooving treatment, low work efficiency, etc., to improve quality and service life, improved compaction uniformity, and high space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

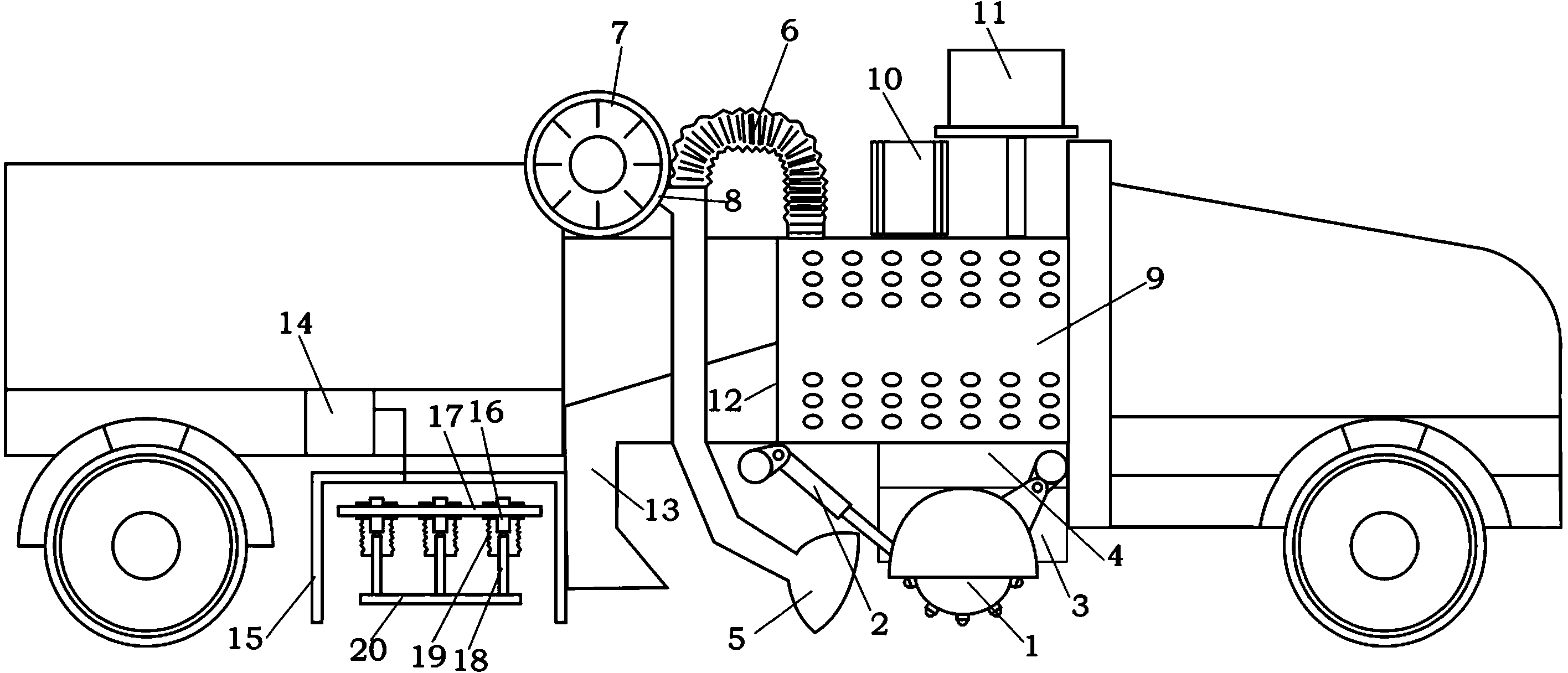

[0014] Example: such as figure 1 , This integrated system device for asphalt pavement planing, milling and repairing includes a car body, and the front and rear of the car body are sequentially equipped with: planing and milling parts, returning scrap parts, microwave mixing and cutting parts, and compacting parts.

[0015] Described planing and milling part comprises engine 3, and engine 3 is connected with planing and milling tool 1 through gearbox 4, and after engine 3 and gearbox 4 are placed in the same horizontal position of planing and milling tool 1, the rotating shaft at the right end of planing and milling tool 1 is installed on On the right side plate of the vehicle frame, the other end is connected with the hydraulic pump 2 cantilever and suspended on the chassis vehicle frame.

[0016] The scrap parts include a fan 7, the fan 7 is connected to the rigid suction plate 5 through the air suction port 8, and the rigid suction plate 5 is connected to the microwave box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com