Continuous air inflating structure for hangar

A technology for inflatable structures and hangars, which is applied to buildings where cars are parked, building types, buildings, etc. It can solve the problems of increasing structural weight and construction cost, difficult to meet the needs of adaptability, difficult to meet bad weather, etc. Anti-wind and snow ability, strong wind-rain-snow ability, ensure the effect of anti-rain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

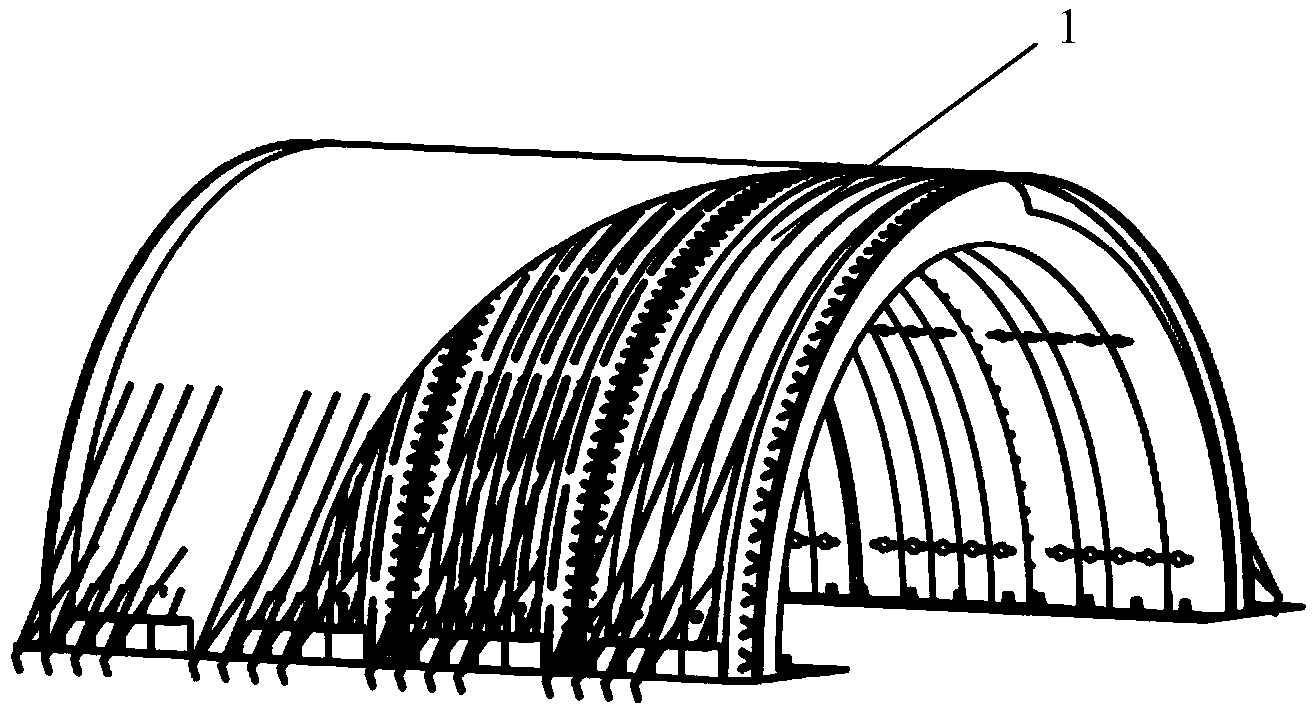

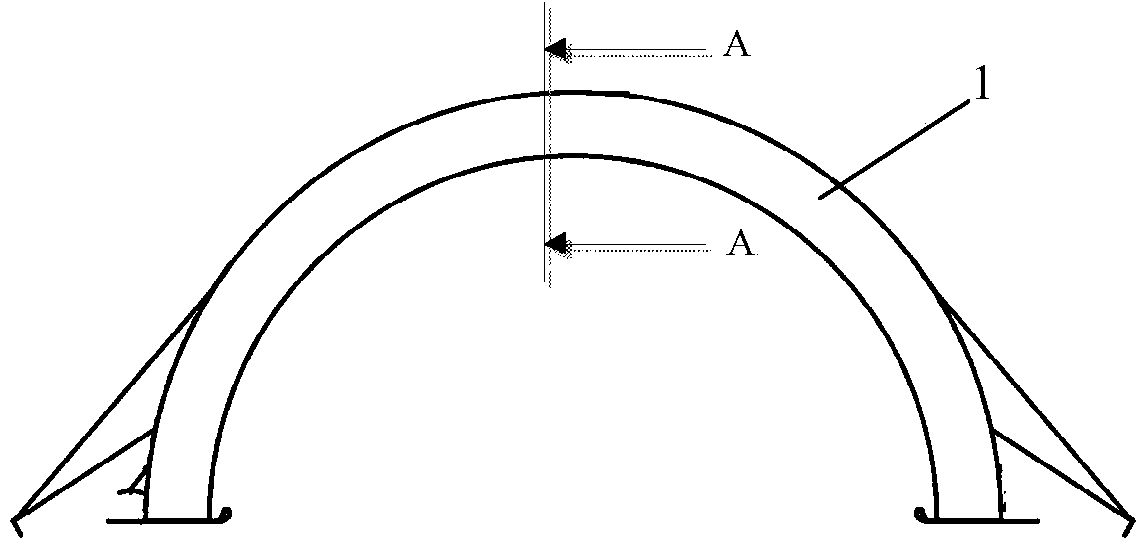

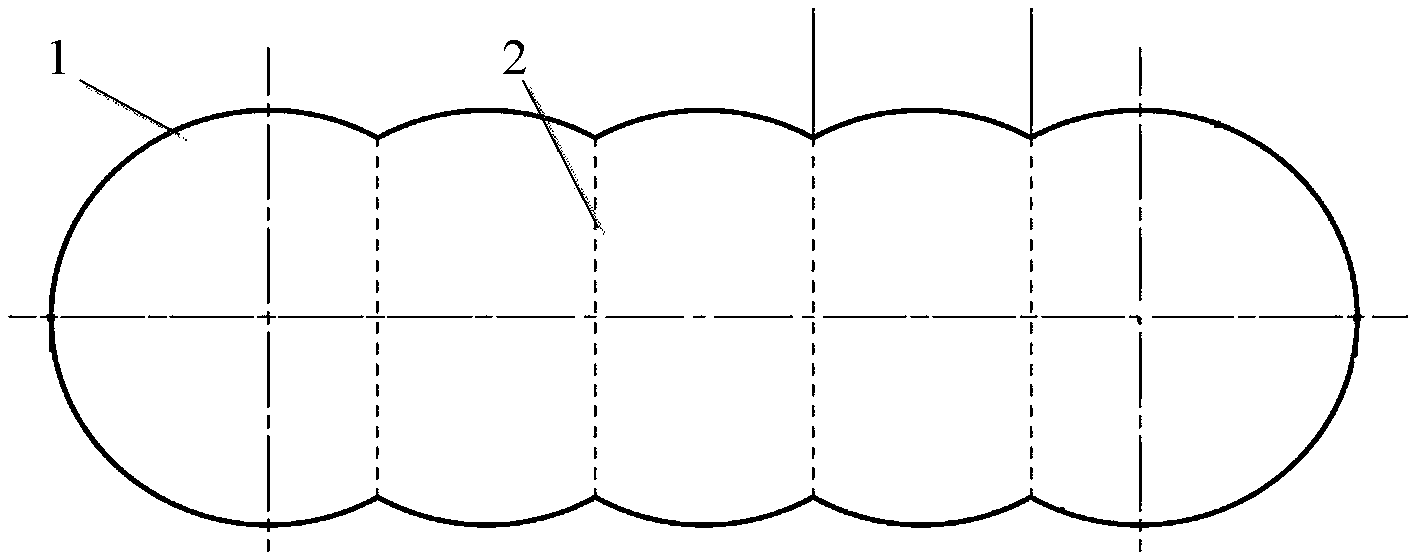

[0026] Such as figure 1 and figure 2 As shown, the main body of the continuous inflatable structure of the hangar is an integral inflatable molding structure formed by connecting a plurality of air ribs 1 . The air rib 1 is a semicircular arch structure.

[0027] figure 1 and figure 2 The main technical features not shown in the above are: the air rib is an arched inflatable cavity structure composed of PVDF coating material hot-pressed by a high-frequency heat-sealing machine, the air rib is connected with a joint, and the joint is made of The joint surface connecting the air ribs and the connecting pipe used to communicate with the cavity between the air ribs constitute a T-shaped structure, and the connecting pipes of the joints between the air ribs are connected by cold glue.

[0028] The PVDF coating material constituting the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com