Multifunctional tunneling machine

A tunnel boring machine, multi-functional technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of long-term high-intensity work by operators, difficult to meet construction period requirements, and difficult to guarantee construction safety, etc. Advanced design and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

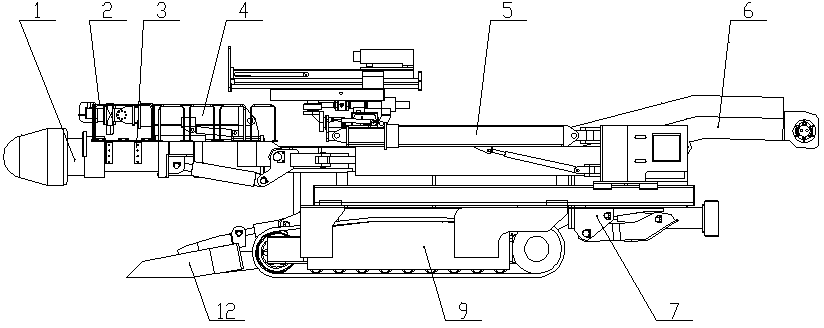

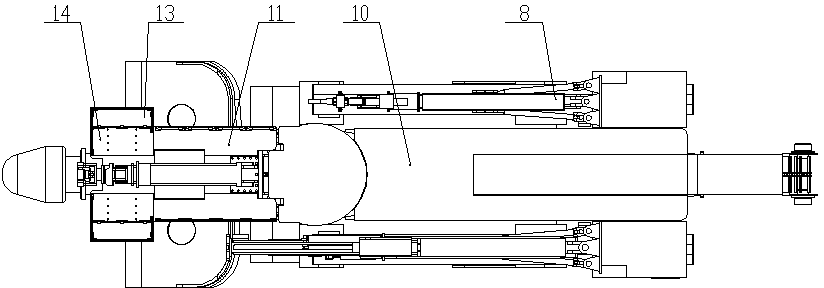

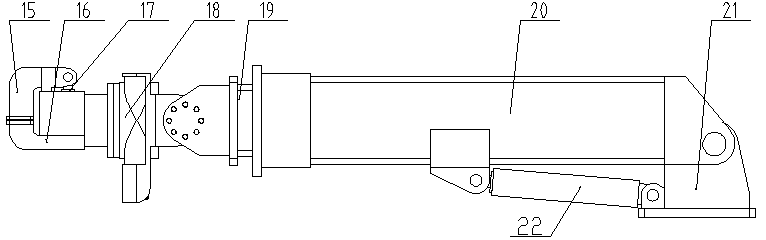

[0027] A multifunctional tunnel boring machine includes a cantilever boring machine, an arch installation machine, an airborne bolt drilling machine, and an airborne wet spraying machine. The arch installation machine is arranged above the front part of the cantilever roadheader, the airborne bolt drill is arranged on both sides of the cantilever roadheader, and the airborne wet spraying machine is also arranged on both sides of the cantilever roadheader.

[0028] Such as figure 1 , 2 As shown, the cantilever roadheader is composed of a cutting part 1, a shovel part 12, a body part 10, a walking part 9, a rear support part 7, a scraper conveyor 6, hydraulic components, electrical components and the like.

[0029] Wherein, the cutting part 1 is hinged at the front end of the body part 10, and the shovel part 12 is hinged at the bottom of the front end of the body part 10; It can be lifted up and down. The front end of the scraper conveyor 6 is hinged at the rear of the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com