Semiconductor laser

A semiconductor and laser technology, applied in the field of lasers, can solve the problems of large parasitic effect, large volume and complex production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

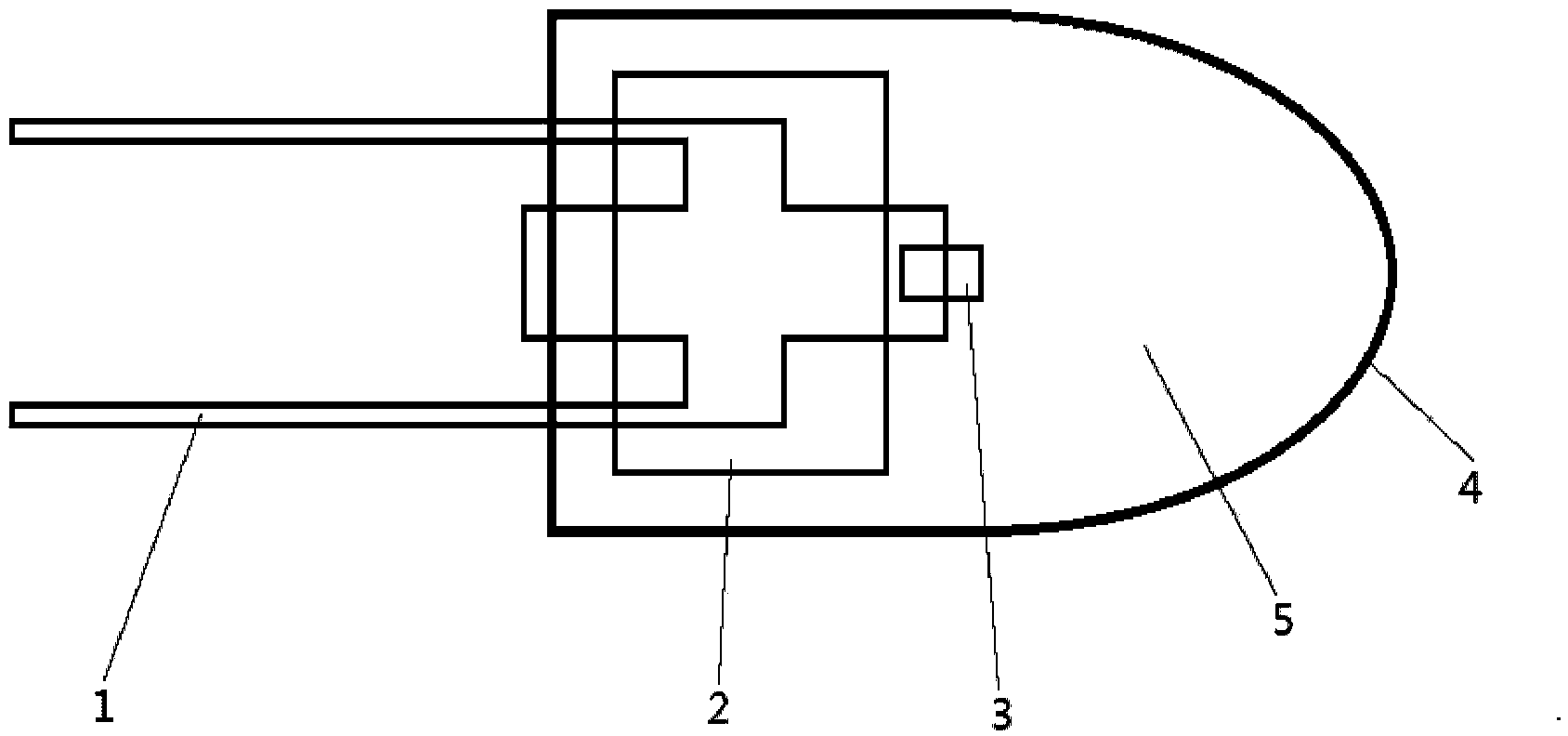

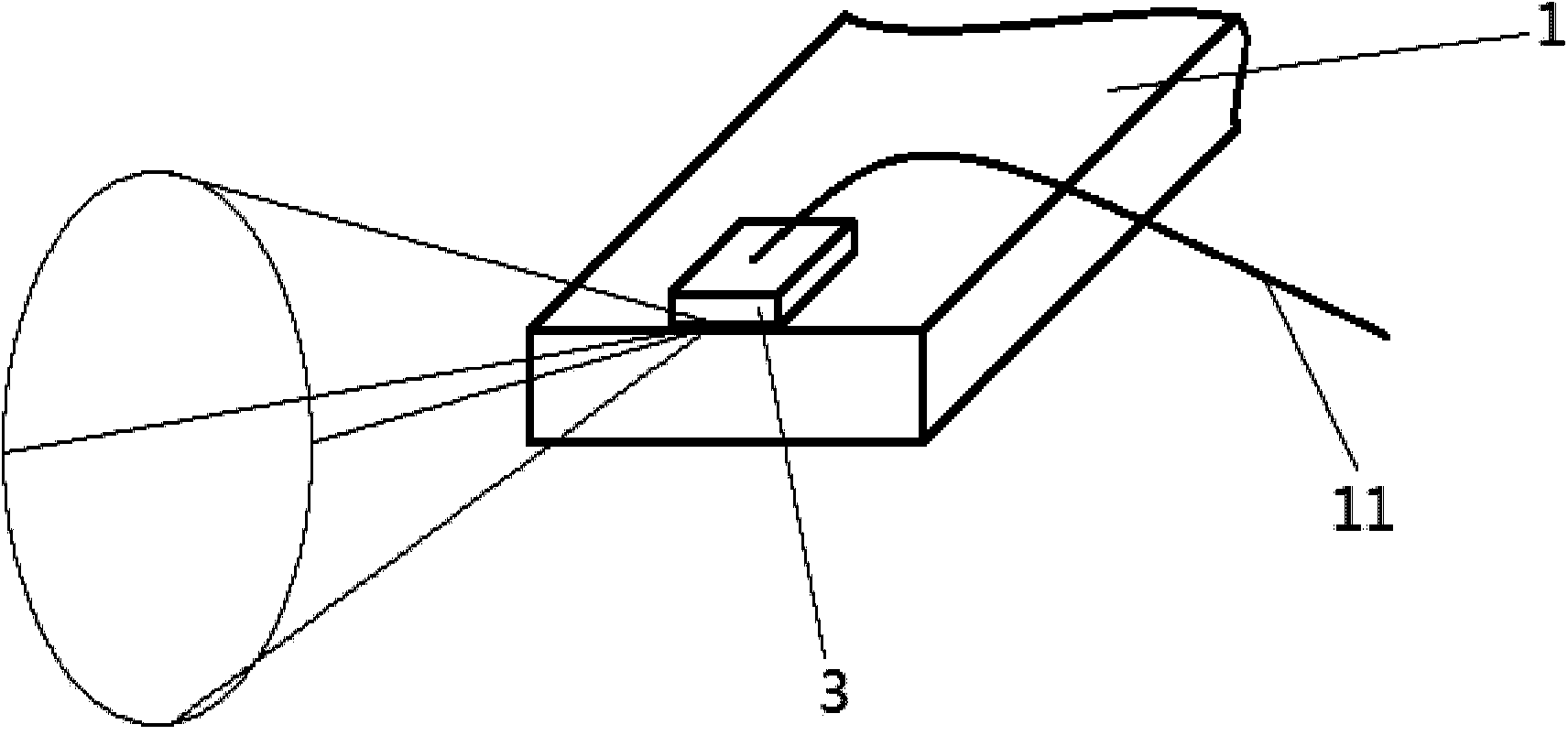

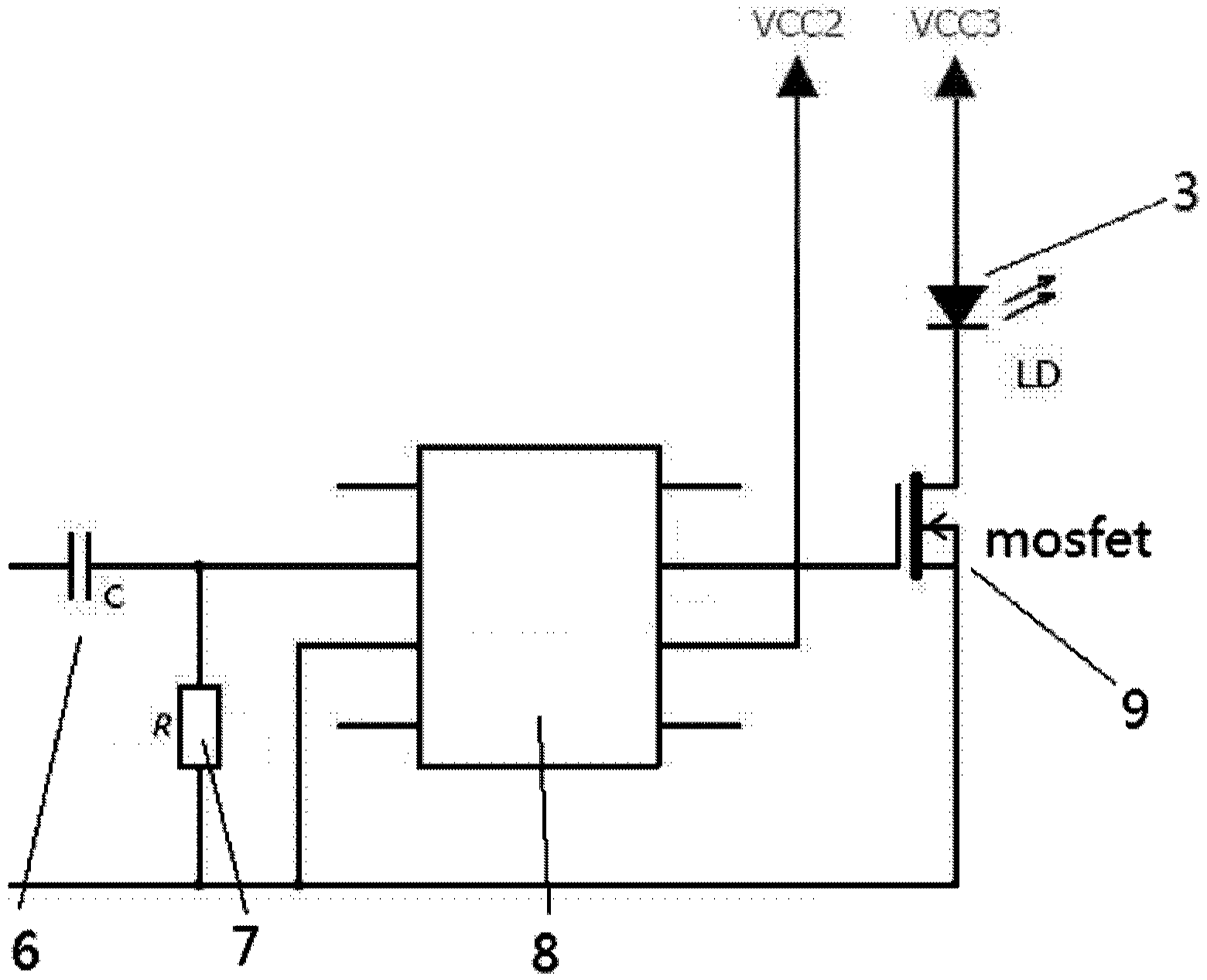

[0019] figure 1 The overall structure diagram of the semiconductor laser proposed by the present invention is shown. The semiconductor laser described above is a device in which all functional components are wrapped by encapsulating materials, and has the functions of signal shaping, signal amplification, laser emission, and beam collimation or shaping. Its appearance is cylindrical, while the light-emitting end surface is ellipsoidal. Such as figure 1 As shown, the semiconductor laser includes a metal bracket 1 , a driving module 2 , a semiconductor laser tube 3 , a beam collimating lens 4 and a packaging material 5 . The layout of each component in the semiconductor laser makes the electrical signal input from the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Divergence angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com