Production method and apparatus for single-slice integrated semiconductor laser array

A laser array, monolithic integration technology, applied in the field of optoelectronics, can solve problems such as the influence of lasing characteristics and the failure of lasers to work normally, and achieve the effects of reducing production costs, reducing manufacturing difficulty, and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

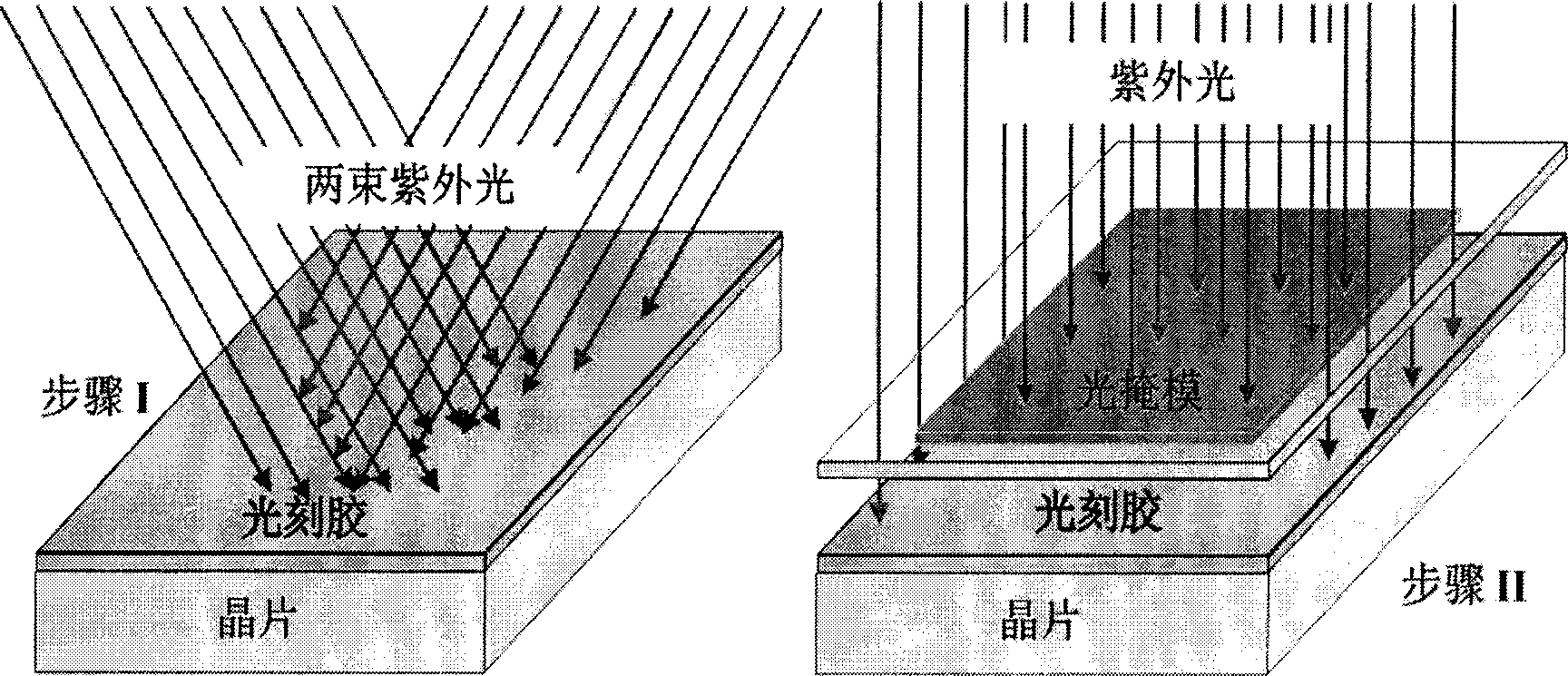

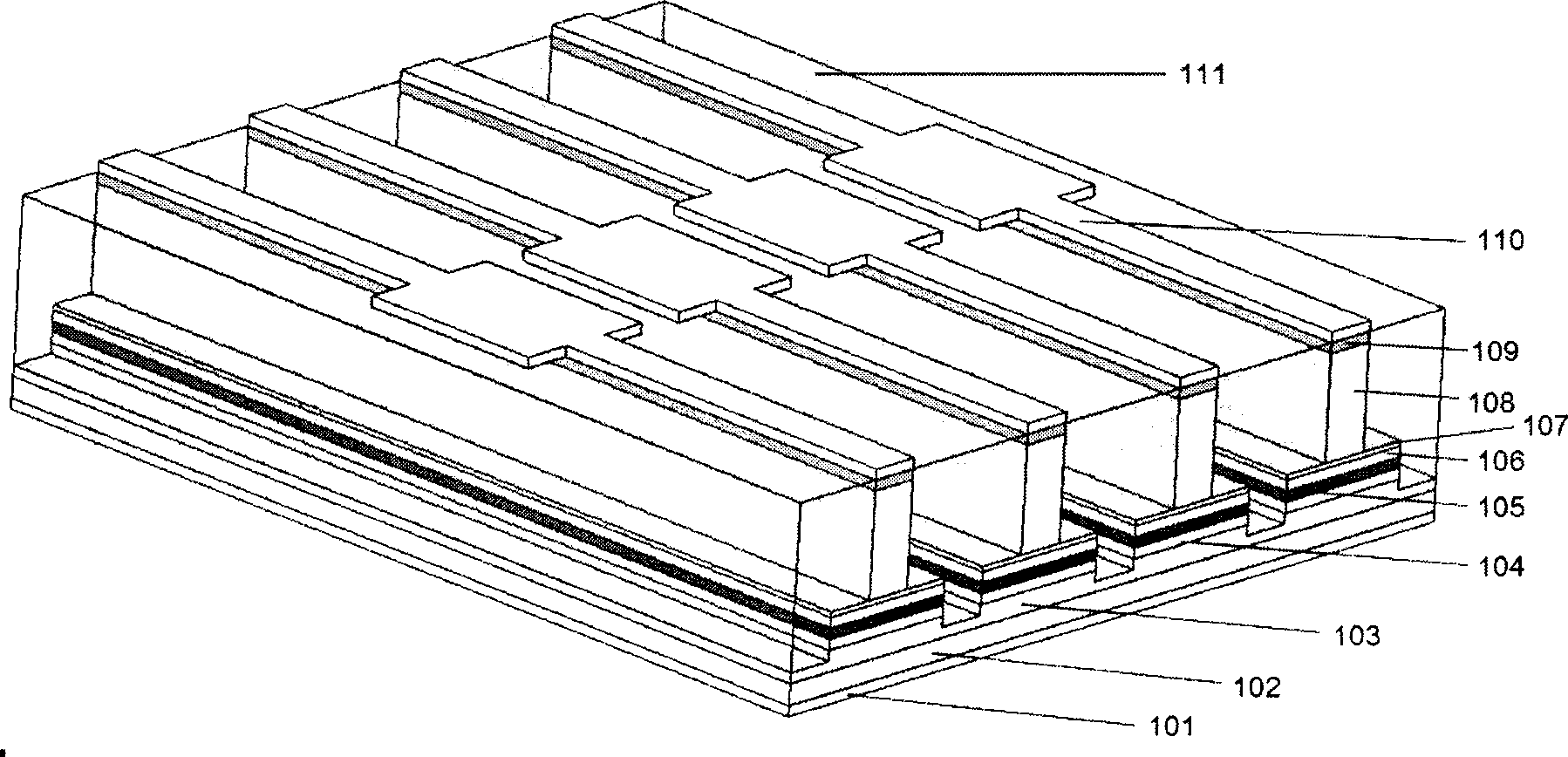

[0039] The structure of the distributed feedback semiconductor laser is that on the n-type substrate material, there are epitaxial n-type InP buffer layer, undoped lattice-matched InGaAsP waveguide layer, strained InGaAsP multiple quantum wells, InGaAsP grating material layer, InGaAsP waveguide layer, InP The confinement layer and the InGaAs ohmic contact layer are sequentially formed; the grating of the InGaAsP grating material layer is a sampled Bragg grating, which is the equivalent grating used for laser lasing; the surface of the equivalent grating of laser lasing is made of SiO with a thickness of 200-400nm 2 Insulation.

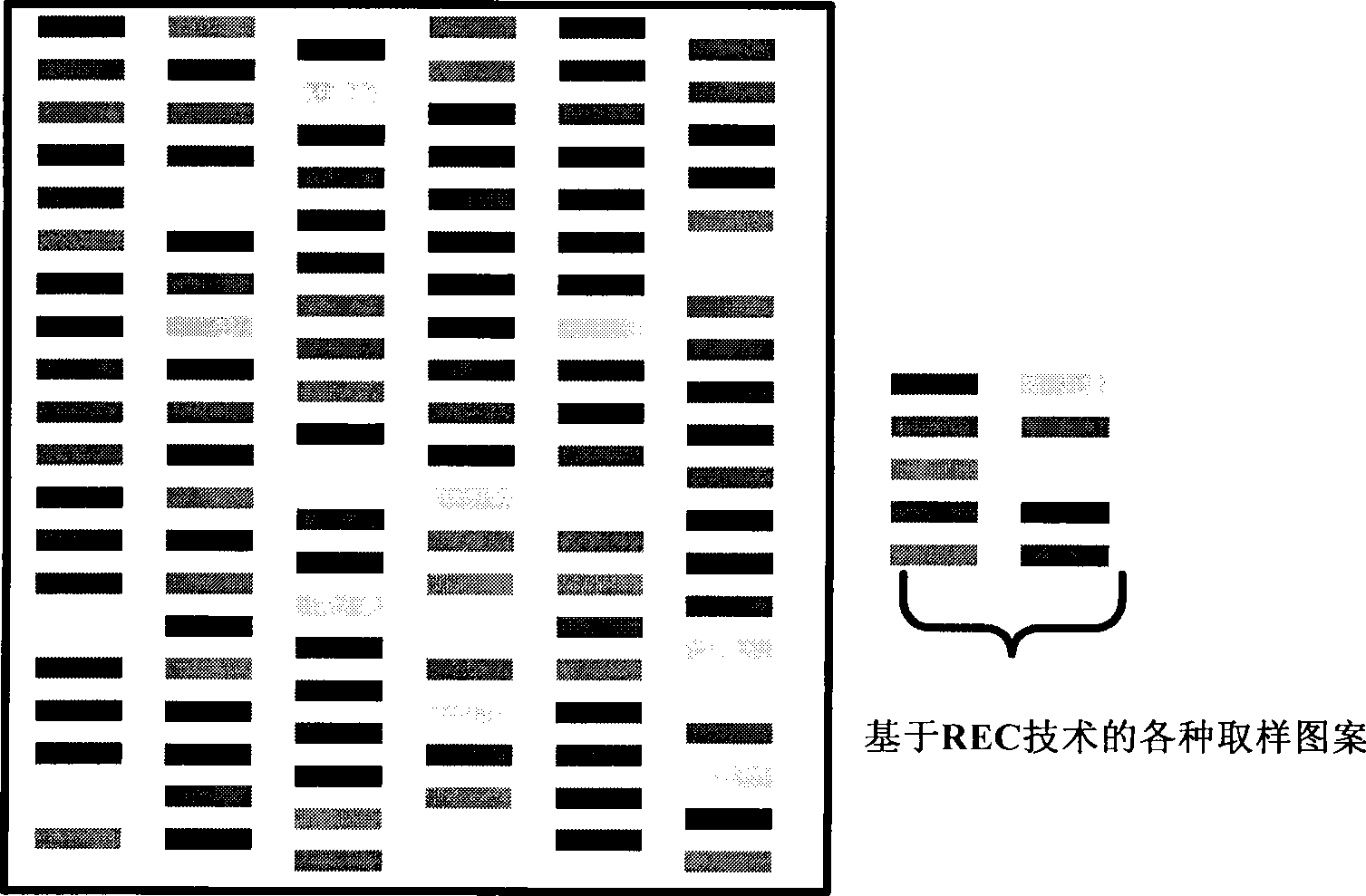

[0040] The sampled Bragg grating has multiple shadow gratings, and the wavelength interval between the shadow gratings is inversely proportional to the sampling period and the effective refractive index of the semiconductor laser waveguide. The following describes a 4-wavelength monolithic integrated DFB laser array with an operating wavelength in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com