Prefabricated warehouse-type high-voltage reactive power compensation device and reactive power compensation method

A technology of compensation device and prefabricated warehouse, which is applied in the direction of reactive power compensation, reactive power adjustment/elimination/compensation, etc. It can solve the problems of complex line laying, potential safety hazards, and inability to meet the needs of the development of intelligent power transmission and transformation substations. Effect of daily control and maintenance, improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

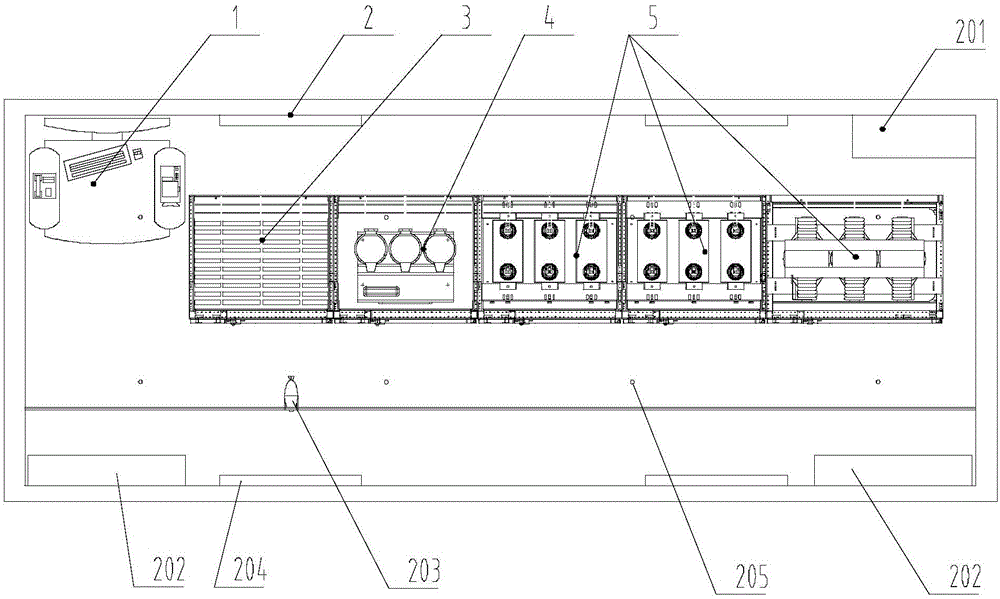

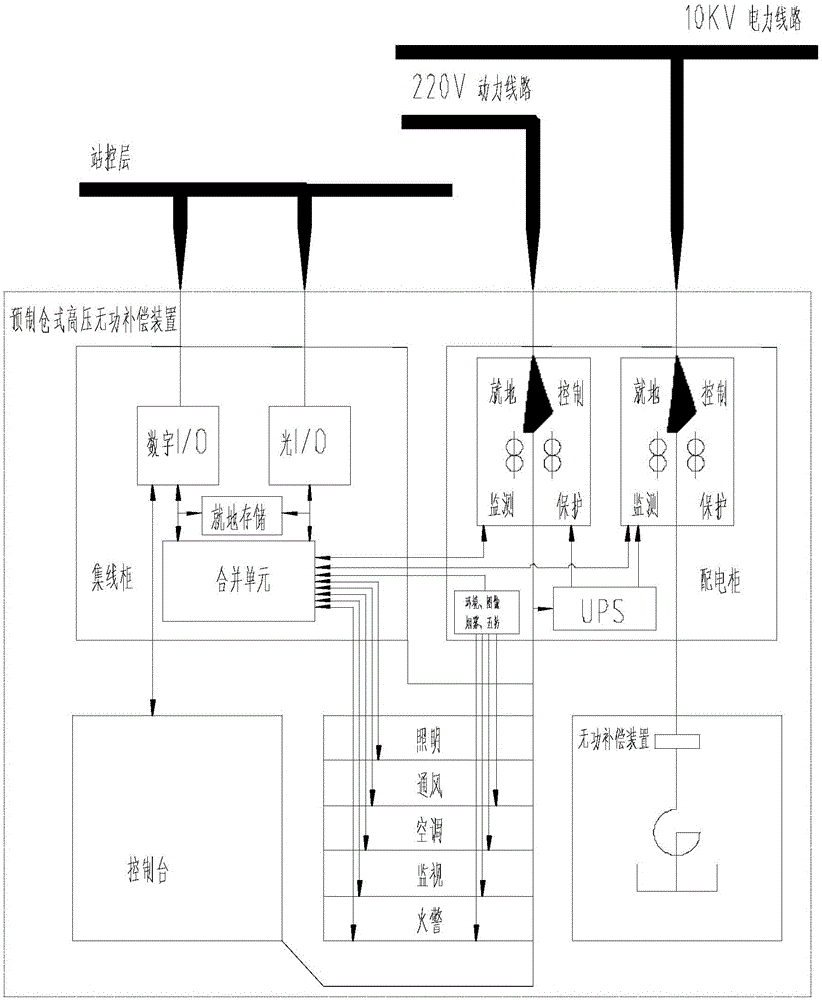

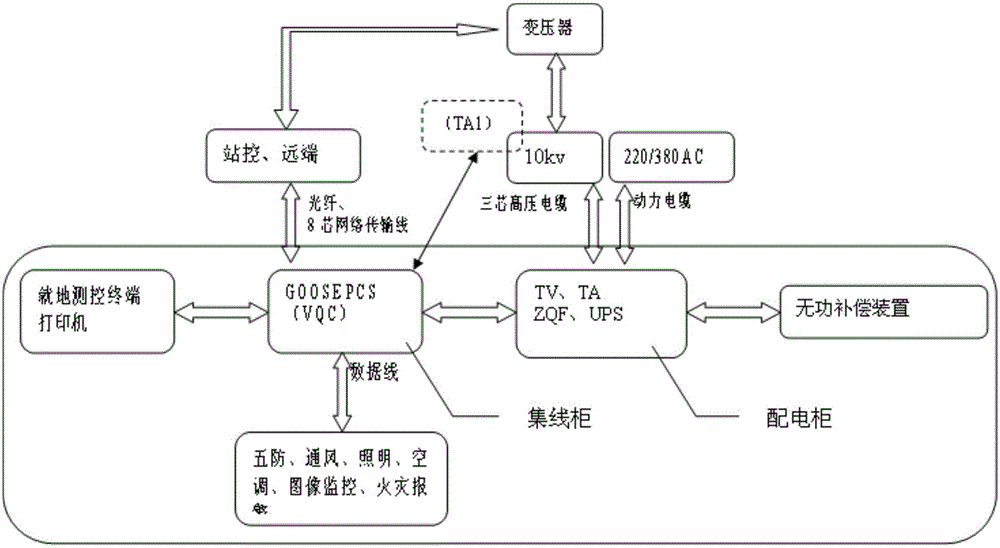

[0021] A prefabricated warehouse type high voltage reactive power compensation device, such as figure 1 As shown, it includes a prefabricated warehouse 2, in which a console 1, a hub cabinet 3, a power distribution cabinet 4, and a reactive power compensation cabinet 5 are installed. The reactive power compensation cabinet 5 is composed of a compensation cabinet and a series reactance cabinet. The prefabricated warehouse 2 is made of standard containers, the size of the warehouse is standardized, and auxiliary facilities such as ventilation, lighting, air conditioning, image monitoring, fire alarm and fire extinguishing are prefabricated, including fire boxes 201, air conditioners 202, monitors 203 and lighting devices 204. The upper part of the prefabricated warehouse 2 A fire meeting 205 connected with the fire box 201 is provided. The reactive power compensation ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com