Microduct-tube winder, double station winder, processing system for empty plastics microduct tubes and method for winding up such tubes

A processing system and technology for micro-pipes, which are applied in the field of micro-pipe pipe winding machines, double-station winders, processing systems for micro-pipes-plastic hollow pipes, and for winding such pipes, can solve the problem of Tube lengthening, unsatisfactory results, loss of tube accuracy, etc. to reduce stress, improve repeatability, and optimize exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The drawings are of a schematic nature only and are used only for the understanding of the invention. The same elements are assigned the same reference numerals. It is possible to omit or replace components according to the invention. It is also possible to transfer features of certain embodiments to other embodiments.

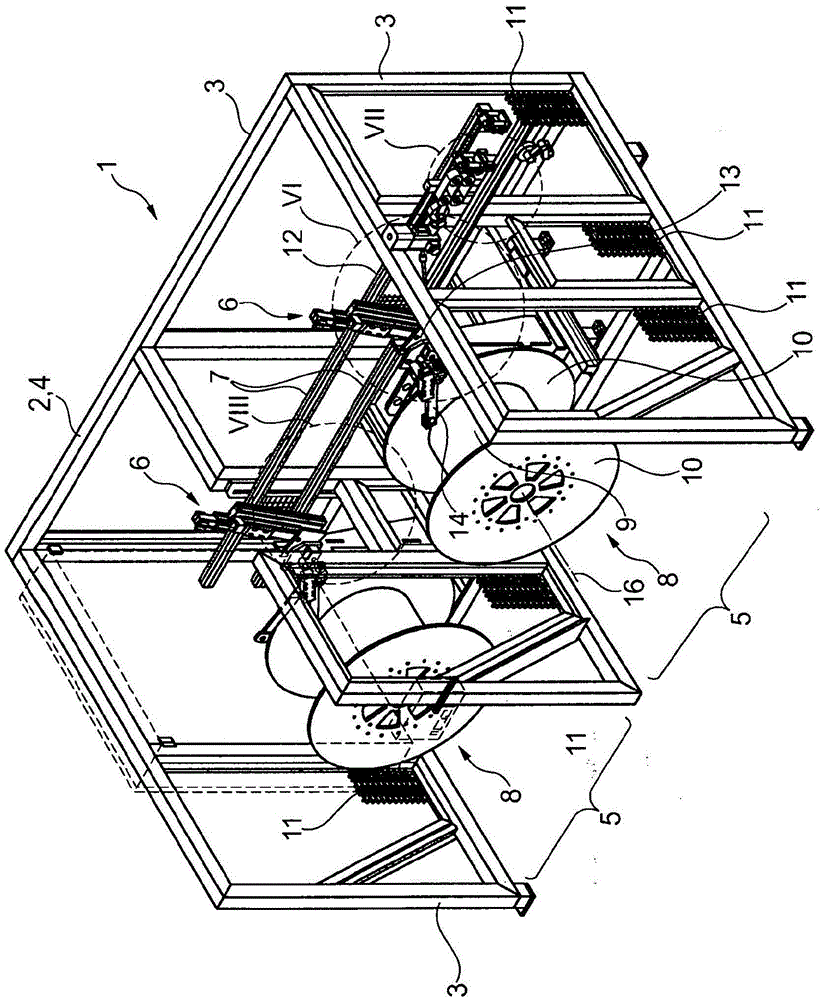

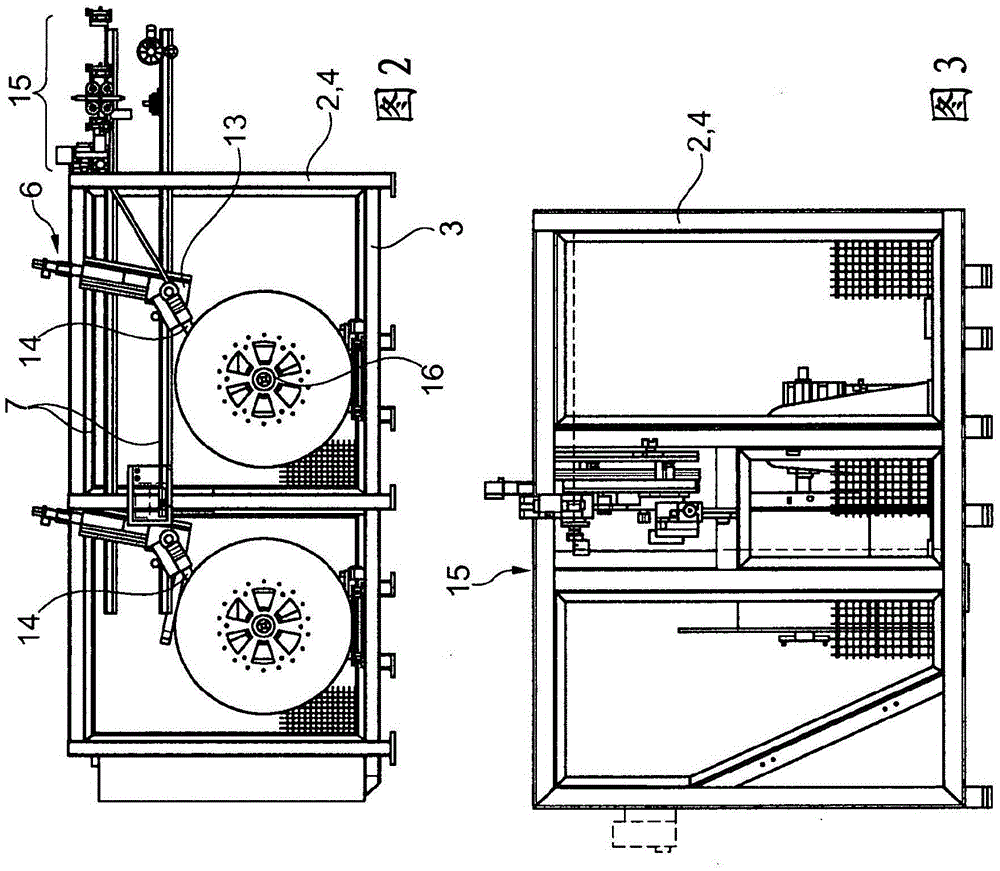

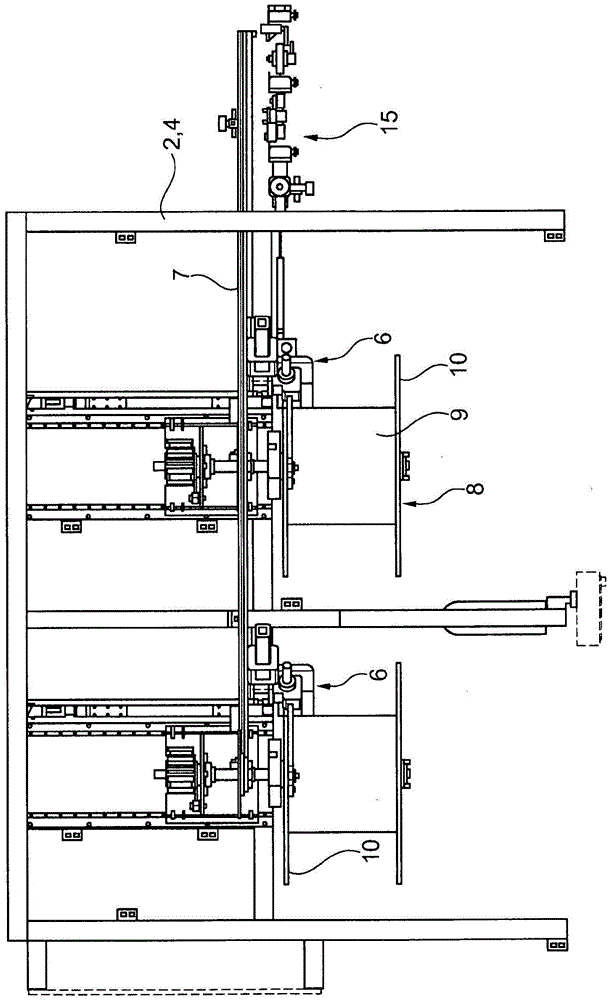

[0090] exist figure 1 shows a double station winding machine 1 according to the invention. The double station winder 1 has a frame 2 . This frame 2 combines the individual carrier tubes / pipes 3 into a support 4 . The support tube / pipe 3 can be designed as a round or angular hollow tube.

[0091] Inside the stand 4 there are two microduct tube winders 5 . Each microduct pipe winder 5 has a pipe guide 6 . In this case, the pipe guide 6 is mounted displaceably on two guide rails 7 . The tube guide 6 feeds microducts, which are empty plastic tubes (not shown), to a reel 8 , wherein the reel 8 has a core 9 between two flanges 10 . The flange 10 can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com