Scissors disconnecting device of aquatic plant harvesting system and aquatic plant harvesting ship with scissors disconnecting device

A detachment device and aquatic weed technology, which is applied to harvesters, transportation and packaging, special-purpose ships, etc., can solve the problems of aquatic weed accumulation, abnormal transportation, and increased labor intensity of workers, so as to achieve high harvesting efficiency and reduce The effect of low labor intensity and simple structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

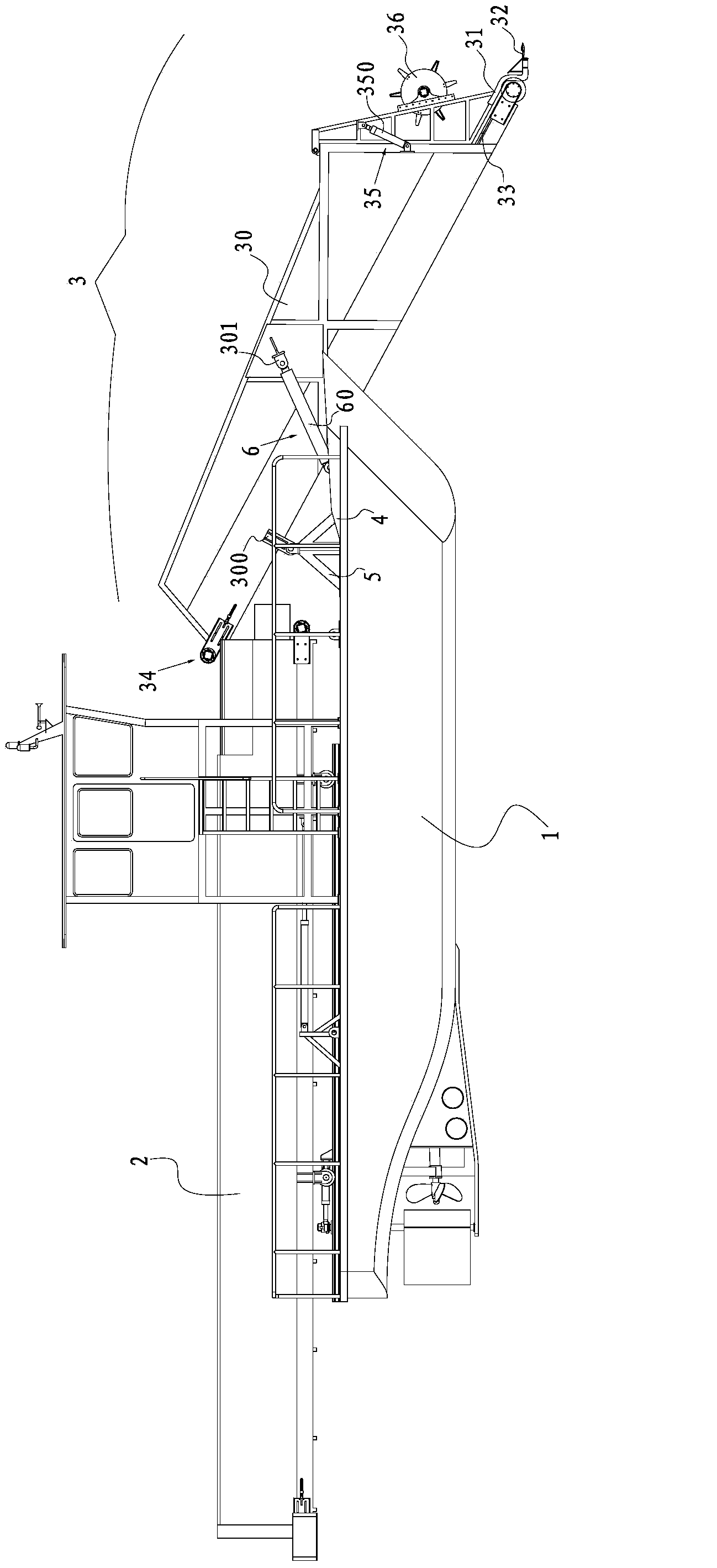

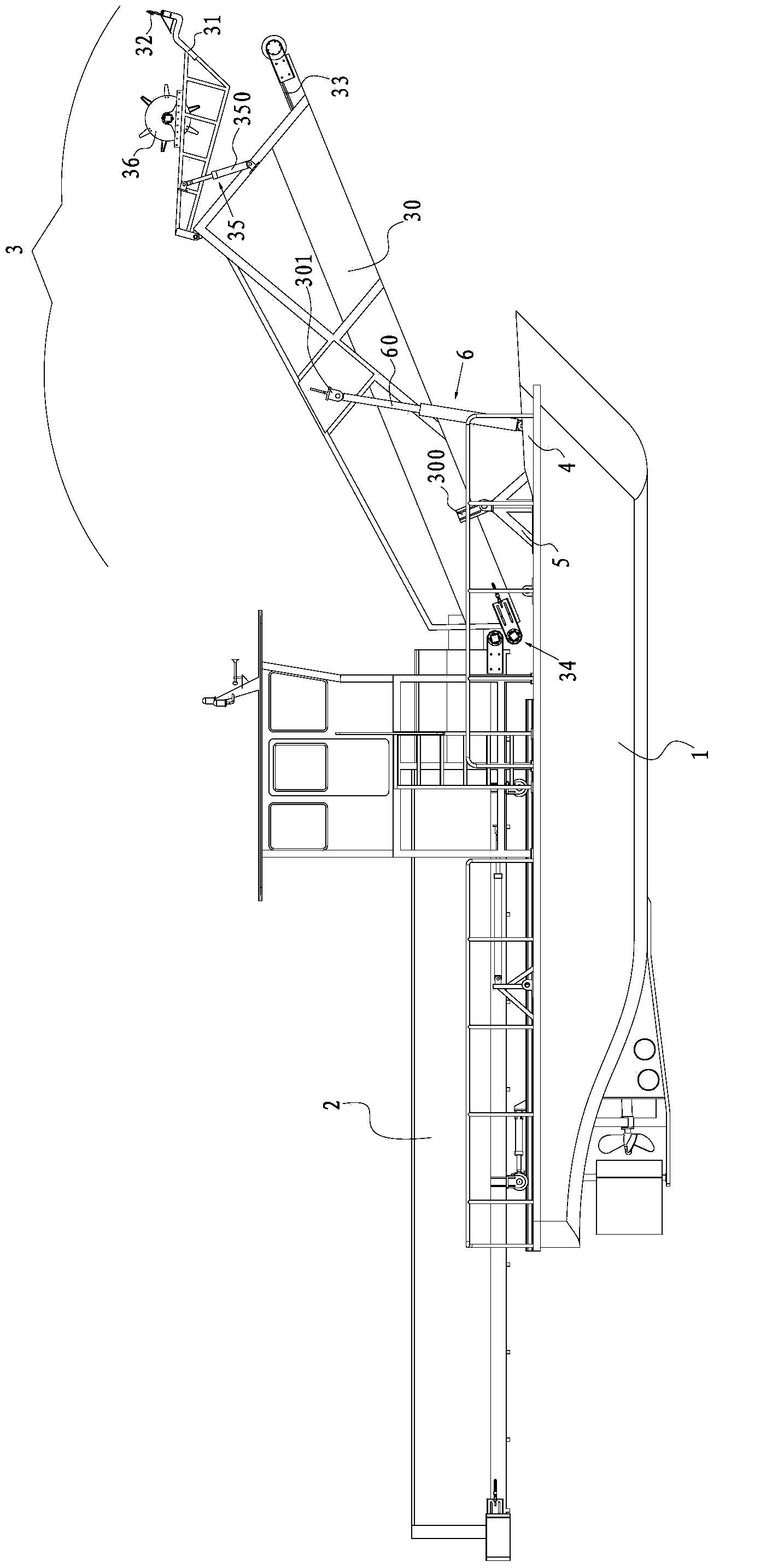

[0021] Such as Figures 1 to 4 As shown, the present embodiment provides aquatic plants harvesting ship, and it comprises hull 1 and hull propulsion device (can be implemented with reference to conventional technology, will not go into details hereinafter), the receiving bin 2 that can be arranged on hull 1 that can be adjusted freely, Waterweed Harvesting System 3.

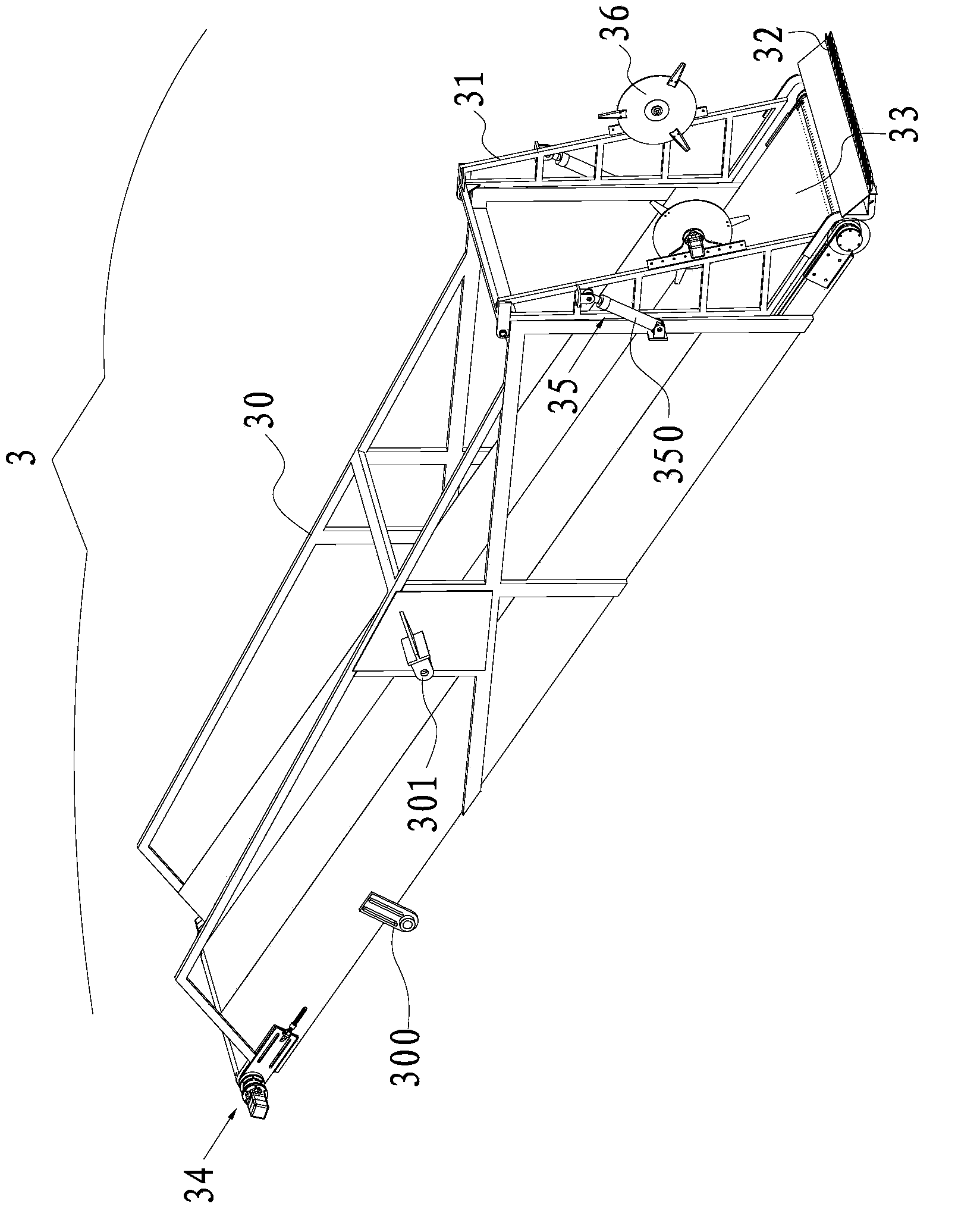

[0022] The above-mentioned aquatic plants harvesting system 3 comprises a harvesting support 30, a harvesting scissors frame 31 positioned at the front end of the harvesting support 30 and a harvesting scissors 32 positioned on the harvesting scissors frame 31, and a harvesting scissors frame 32 positioned at the rear of the harvesting scissors frame 31 and arranged on the harvesting frame 30. Conveyor mesh belt 33 and the first driving mechanism 34 that drives the conveyance mesh belt 33 to transfer aquatic plants, wherein the harvesting scissors frame 31 is arranged on the harvesting support 30 in rotation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com