Low-noise modular automotive air dryer

A technology of low-noise modules and air dryers, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of endangering human health, sharpness, loud exhaust sound, etc., and improve safety and service life Long, takes up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

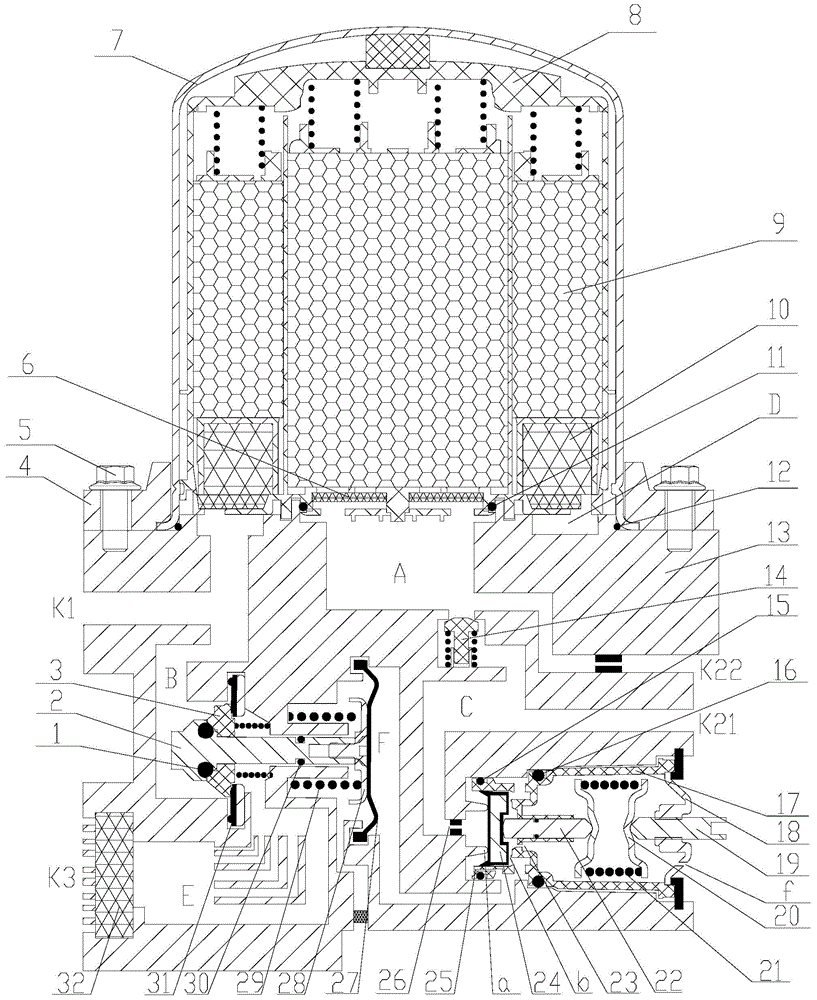

[0019] refer to figure 1 , a low-noise modular vehicle air dryer, comprising a valve body 13, a drying tank, a pilot control valve and an unloading valve, the drying tank, the pilot control valve and the unloading valve are respectively installed on the valve body, the The pilot control valve is a rubber piston pilot control valve, and the unloading valve is a diaphragm unloading valve. The drying tank is composed of a cylinder 7, an annular channel D, a drying tank liner 8, a molecular sieve 9, a filter membrane 6, and a compression ring 4, and passes through the second O-ring 11, the third O-ring 12 and the valve body 13 , The bolt 5 isolates and seals the connection. The pilot control valve consists of a fourth O-ring 15, a fifth O-ring 16, a pilot control valve body 17, an adjustment seat 18, a pressure regulating screw 19, a spring seat 20, a pressure regulating spring 21, a push rod 22 and a rubber piston Valve 24 constitutes. The unloading valve is composed of a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com